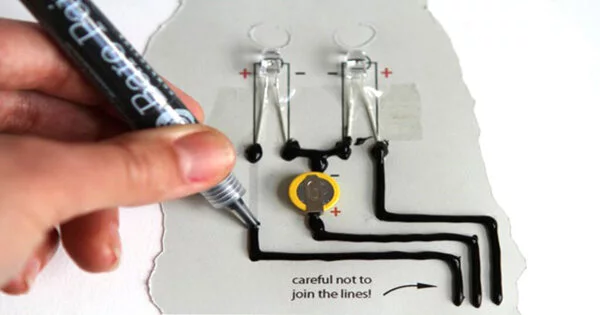

Conductive ink is a type of ink that produces a printed object that conducts electricity. It is used in a variety of applications where traditional circuitry would be too complex or impractical, such as printed electronics, flexible electronics, sensors, RFID (radio-frequency identification) tags, touchscreens, and others. Ink is typically infused with graphite or other conductive materials to produce it.

Conductive ink has the advantage of allowing you to create circuits or conductive traces on unusual substrates such as paper, fabric, plastic, or even curved surfaces. Because of the emergence of nanotechnology, there has been a growing interest in replacing metallic materials with nanomaterials. Graphene and carbon nanotube-based conductive ink, among other nanomaterials, are gaining popularity due to their high electrical conductivity and surface area.

Metals or metal alloys such as silver, copper, gold, or carbon-based materials such as graphite or carbon nanotubes can be used as conductive materials in these inks. These materials give the ink its conductive properties, which enable it to carry electrical current. The ink is frequently formulated to be compatible with printing techniques such as screen printing, inkjet printing, and even 3D printing, allowing for the creation of complex electronic patterns on various surfaces.

Recently, more emphasis has been placed on using eco-friendly conductive ink with water as a solvent rather than organic solvents, which are harmful to the environment. However, the high surface tension of water precludes its use. Various natural and synthetic surfactants are now used to reduce the surface tension of water and ensure uniform nanomaterials dispersibility for smooth printing and wide application.

Particle-based inks, which contain conductive particles suspended in a liquid carrier, and polymer-based inks, which contain conductive polymers dissolved in a solvent, are two types of conductive inks. The formulation of the ink is determined by the specific application as well as the desired conductivity, flexibility, and durability of the printed circuit.

One of the benefits of conductive inks is their adaptability. They allow for the creation of flexible and lightweight electronic devices, which are suitable for applications such as wearable technology, smart packaging, and others. It should be noted, however, that the conductivity of these inks may not be as high as that of traditional metal conductors, which may limit their use in certain high-performance applications.

Today, silver inks have a variety of applications, including printing RFID tags, which are used in modern transit tickets, as well as improvising or repairing circuits on printed circuit boards. Membranes with printed circuits in computer keyboards detect when a key is pressed. Windshield defrosters are also printed and consist of resistive traces applied to the glass.

Conductive inks have received a lot of attention and development in recent years as researchers and businesses look for new ways to incorporate electronics into various aspects of daily life.