Dielectric barrier discharges (DBDs) are plasmas generated in configurations with an insulating (dielectric) material between the electrodes which is responsible for a self-pulsing operation. DBD is the electrical discharge between two electrodes separated by an insulating dielectric barrier. DBDs are a typical example of nonthermal atmospheric or normal pressure gas discharges. Initially used for the generation of ozone, they have opened up many other fields of application. Originally called silent (inaudible) discharge and also known as ozone production discharge or partial discharge, it was first reported by Ernst Werner von Siemens in 1857. The use of dielectric barrier discharge (DBD) to produce cold plasma showed a potential industrial application at low cost and convenience.

Dielectric-barrier discharge (DBD) is a typical example of nonthermal atmospheric or normal pressure gas discharges. Initially used for the generation of ozone, they have opened up many other fields of application.

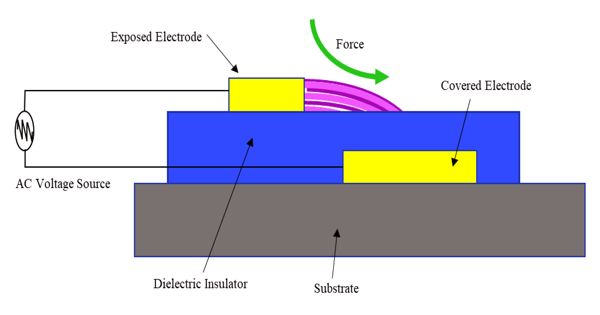

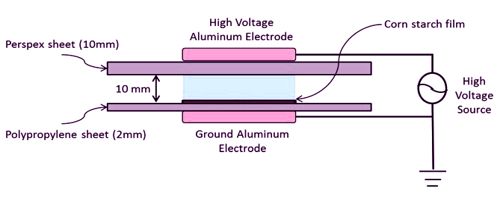

On right, the schematic diagram shows a typical construction of a DBD wherein one of the two electrodes is covered with a dielectric barrier material. The most important characteristic of DBDs is that non-equilibrium plasma conditions can be provided at elevated pressure, for example, atmospheric pressure. The lines between the dielectric and the electrode are representative of the discharge filaments, which are normally visible to the naked eye. Below this, the photograph shows an atmospheric DBD discharge occurring in between two steel electrode plates, each covered with a dielectric (mica) sheet. The filaments are columns of conducting plasma, and the foot of each filament is representative of the surface accumulated charge. The flexibility of DBD configurations with respect to geometrical shape, operating medium and operating parameters is remarkable. However, this technology seems to accelerate oxidative pathways; for this reason, further studies to investigate the use of antioxidants in combination with cold plasma as “hurdle technology” to minimize this negative effect are suggested.

Dielectric barrier discharge atmospheric air plasma treatment of high amylose corn starch films

Process

The process normally uses high voltage alternating current, ranging from lower RF to microwave frequencies. However, other methods were developed to extend the frequency range all the way down to DC. Dielectric barrier discharge microplasma is a nonthermal plasma discharge at atmospheric pressure which due to the micrometer size dielectric layer between the grounded and high-voltage energized electrodes enables to drive the device at less than 1 kV. One method was to use a high resistivity layer to cover one of the electrodes. This is known as the resistive barrier discharge. Microplasma is an economical and ecological alternative for conventional technologies used for NOx removal, indoor air cleaning, surface treatment of polymers, biomedical applications such as transdermal drug delivery, or as an actuator. Another technique using a semiconductor layer of gallium arsenide (GaAs) to replace the dielectric layer, enables these devices to be driven by a DC voltage between 580 V and 740 V.