Densified coal is the product of the Coldry Process coal upgrading technology that removes moisture from low-rank coals such as sub-bituminous and lignite/brown coal. It is a technology that has been developed for transforming run-of-mine brown coals into a dense, dry, hard product. The densification process raises the calorific value of low-rank coal to equal or exceed that of many export-grade black coals. The densified coal has an advantage over black coal in that dependant upon the coal stock selected the mineral content can be quite low.

Coke is made by heating coal without air. The liquids and vapors are driven off leaving coke. Raw coal is attritioned in batch or continuous kneaders to a mean particle size of approximately 10 μm. This size reduction releases the water naturally occurring within the porous coal structure, such that a paste-like material results. Densified coal resulting from the Coldry Process is regarded as a black coal equivalent or replacement for black coal. The process is more general and has been applied to other feedstocks — peat and some lignites as well as brown coals have been found suitable. The need to reduce carbon emissions has encouraged more research into the use of biomass energy in place of coal.

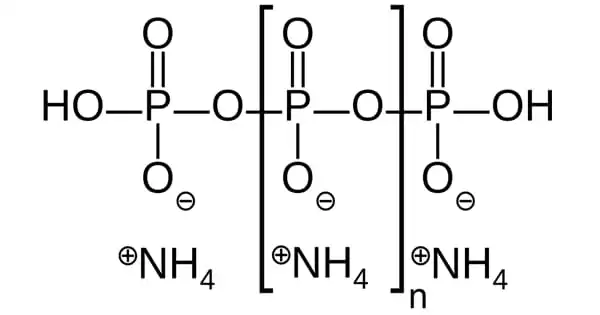

Fig: Coldry technology for low-rank coal drying

The Coldry Process is a patented coal upgrading technology being developed in Victoria, Australia by Environmental Clean Technologies Limited based on ‘brown coal densification’. It has been developed specifically to improve low-rank brown coal (lignite) and some forms of sub-bituminous coal by removing the majority of the naturally occurring moisture content; harden and densify the coal; raise the calorific value of the coal; and transform the coal into a stable (lower spontaneous combustion risk), exportable black coal equivalent product for use by black coal-fired power generators to produce electricity or as a feedstock for downstream processes such as coal-to-gas, oil, and other high-value chemicals. A hard, low-moisture content briquette-equivalent product is produced by the evaporative removal of water at or near ambient atmospheric drying conditions.

Advantages

The advantages of this densified brown coal process are that a hard, dense, fuel product can be manufactured from raw brown coal of high initial water content without the need for, or prolonged, expensive drying conditions at elevated temperatures. The main advantages are:

- simplified mechanical handling and feeding

- uniform combustion in boilers

- reduced dust production

- reduced possibility of spontaneous combustion in storage

- simplified storage and handling infrastructure, lowering capital requirements at the combustion plant

- reduced cost of transportation due to increased energy density.