Crystalline silicon is a material commonly used in the production of electronic devices such as solar cells, integrated circuits, and computer chips. It refers to the crystalline forms of silicon, either polycrystalline silicon (poly-Si, which is made up of small crystals) or monocrystalline silicon (mono-Si, a continuous crystal). It is a semiconductor material, which means that it can conduct electricity under certain conditions but not others, making it an essential component in electronic circuits. The dominant semiconducting material used in photovoltaic technology for the production of solar cells is crystalline silicon. To generate solar power from sunlight, these cells are assembled into solar panels as part of a photovoltaic system.

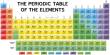

Crystalline silicon is a form of silicon that has a regular, repeating atomic structure, like a three-dimensional lattice. It is composed of atoms with four valence electrons, which means they can form covalent bonds with up to four other atoms. These bonds create the crystal lattice structure, which gives crystalline silicon its unique electrical properties.

In electronics, crystalline silicon is the monocrystalline form of silicon that is used to make microchips. This silicon has far fewer impurities than is required for solar cells. Chemical purification to produce Hyper-pure Polysilicon is followed by a recrystallization process to grow monocrystalline silicon in the production of semiconductor-grade silicon. After that, the cylindrical boules are cut into wafers for further processing.

Solar cells made of crystalline silicon are commonly referred to as conventional, traditional, or first generation solar cells because they were developed in the 1950s and have remained the most common type to this day. They are sometimes referred to as wafer-based solar cells because they are made from 160-190 m thick solar wafers (slices from bulks of solar grade silicon).

Solar cells made of c-Si are single-junction cells that are more efficient than their competitors, which are second-generation thin-film solar cells, the most important of which are CdTe, CIGS, and amorphous silicon (a-Si). Amorphous silicon is an allotropic variant of silicon, and the term “amorphous” refers to its non-crystalline form.

There are two types of crystalline silicon: monocrystalline and polycrystalline. Monocrystalline silicon is made from a single crystal, while polycrystalline silicon is made up of many small crystals. Monocrystalline silicon is generally considered to be of higher quality, but it is more expensive to produce.

In the solar industry, crystalline silicon is the most commonly used material for solar cells. Solar panels made from crystalline silicon can convert sunlight into electricity with high efficiency, making them an important component in the transition to renewable energy.