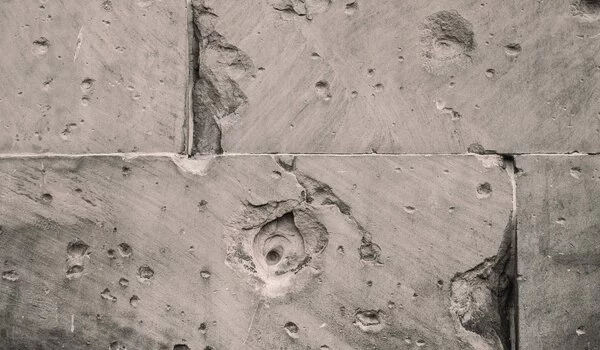

Carbon-negative concrete is a type of concrete that removes more carbon dioxide from the atmosphere during production than it emits. This is a significant step toward reducing the carbon footprint of the construction industry, which contributes significantly to global greenhouse gas emissions. A viable formula for a carbon-negative, environmentally friendly concrete that is nearly as strong as regular concrete has been developed at Washington State University.

In a proof-of-concept experiment, the researchers infused regular cement with environmentally friendly biochar, a type of charcoal made from organic waste that was previously strengthened with concrete wastewater. The biochar could absorb up to 23% of its weight in carbon dioxide from the air while maintaining a strength comparable to ordinary cement.

The study has the potential to significantly reduce carbon emissions from the concrete industry, which is one of the most energy- and carbon-intensive of all manufacturing industries. The research, which was led by doctoral student Zhipeng Li, was published in the journal Materials Letters.

We’re committed to finding novel ways to divert waste streams to beneficial uses in concrete; once we identify those waste streams, the next step is to see how we can wave the magic wand of chemistry and turn them into a resource.

Xianming Shi

“We’re very excited that this will contribute to the mission of zero-carbon built environment,” said Xianming Shi, a professor in WSU’s Department of Civil and Environmental Engineering and the paper’s corresponding author.

Every year, more than 4 billion tons of concrete are produced worldwide. Ordinary cement production necessitates high temperatures and the combustion of fuels. Because the limestone used in its production decomposes and emits carbon dioxide, cement production is thought to account for about 8% of total carbon emissions by human activities worldwide.

Researchers have tried adding biochar as a substitute in cement to make it more environmentally friendly and reduce its carbon footprint, but adding even 3% of biochar dramatically reduced the strength of the concrete. After treating biochar in the concrete washout wastewater, the WSU researchers were able to add up to 30% biochar to their cement mixture. The paste made of biochar-amended cement was able to reach a compressive strength after 28 days comparable to that of ordinary cement of about 4,000 pounds per square inch.

“We’re committed to finding novel ways to divert waste streams to beneficial uses in concrete; once we identify those waste streams, the next step is to see how we can wave the magic wand of chemistry and turn them into a resource,” Shi explained. “The trick really is in the interfacial engineering – how you engineer the interfaces in the concrete.”

The caustic concrete washout water is a potentially hazardous waste product of concrete production. According to Shi, the wastewater is very alkaline but also a good source of calcium. The calcium was used to induce the formation of calcite, which benefits the biochar and, eventually, the concrete that incorporates the biochar.

“Most other researchers were only able to add up to 3% biochar to replace cement, but we’re demonstrating the use of much higher dosages of biochar because we’ve figured out how to engineer the surface of the biochar,” he explained.

Because of the synergy between the highly alkaline wastewater with a high calcium content and the highly porous biochar, calcium carbonate precipitated onto or into the biochar, strengthening it and allowing for the capture of carbon dioxide from the air. The material is expected to continue sequestering carbon dioxide for the lifetime of the concrete, which is typically 30 years in pavement and 75 years in bridges.

The researchers have been working with the Office of Commercialization to protect their intellectual property and have filed a provisional patent application on their carbon-negative concrete work in order to commercialize it. The Washington Research Foundation recently awarded them a seed grant to produce more data for a variety of use cases. They are also actively seeking building and construction industry partners to scale up production for field demonstrations and licensing of this WSU technology.