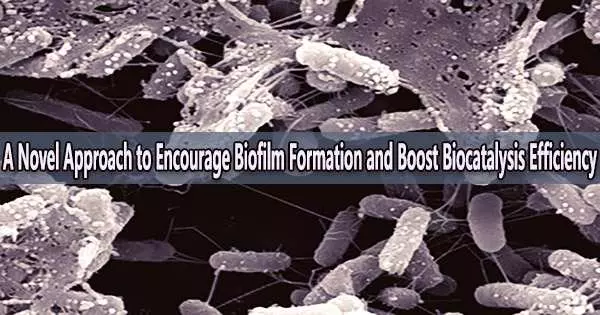

A report from Birmingham scientists that was just published in Materials Horizons describes a novel technique for improving biocatalysis efficiency.

In order to create goods that cannot be produced through chemical synthesis, biocatalysis uses enzymes, organisms, or microbes to catalyze chemical processes in sectors like the food and chemical ones. On a large scale, it can create medications, fine chemicals, or food additives.

The fact that the most frequently used microbes, such as probiotics and non-pathogenic strains of Escherichia coli, are not always adept at forming biofilms growth-promoting ecosystems that create a protective microenvironment around communities of microbes, boost their resilience, and thereby increase productivity represents a significant challenge in biocatalysis.

This problem is normally solved by genetic engineering, but researchers Dr. Tim Overton from the university’s School of Chemical Engineering, and Dr. Francisco Fernández Trillo from the School of Chemistry, both of whom are members of the Institute of Microbiology and Infection, set out to create an alternative method to bypass this costly and time-consuming process.

The E. coli bacterium, one of the most extensively studied microorganisms, is frequently utilized in biocatalysis. The researchers discovered a library of synthetic polymers and evaluated them for their capacity to cause biofilm development in E. coli.

This screening used a strain of E. coli (MC4100) that is widely used in fundamental science to study genes and proteins and is known to be poor at forming biofilms, and compared it to another E. coli strain PHL644, an isogenic strain obtained through evolution that is a good biofilm former.

We explored a broad chemical space and identified the best performing chemistries and polymers that increase the biocatalytic activity of E. coli, a workhorse in biotechnology. This has resulted in a small library of synthetic polymers that increase biofilm formation when used as simple additives to microbial culture. To the best of our knowledge, currently there are no methods that provide this simplicity and versatility when promoting biofilms for beneficial bacteria.

Dr. Francisco Fernández Trillo

This screening revealed the chemistries that are best suited to stimulating biofilm formation. Mildly cationic polymers were surpassed by hydrophobic polymers, while the comparable aliphatic polymers were significantly outperformed by aromatic and heteroaromatic derivatives.

When both strains were cultured in the presence of these polymers, the researchers continued to monitor their biomass and biocatalytic activity and discovered that MC4100 was on par with PHL644 in both areas.

Further studies examined how the polymers stimulate these profound increases in activity. In this case, the research showed that the polymers precipitate in solution and function as coagulants, causing flocculation, a natural process that causes bacteria to build biofilms, to be stimulated.

Dr. Fernandez-Trillo said: “We explored a broad chemical space and identified the best performing chemistries and polymers that increase the biocatalytic activity of E. coli, a workhorse in biotechnology. This has resulted in a small library of synthetic polymers that increase biofilm formation when used as simple additives to microbial culture. To the best of our knowledge, currently there are no methods that provide this simplicity and versatility when promoting biofilms for beneficial bacteria.”

“These synthetic polymers may bypass the need to introduce the traits for biofilm formation through gene editing, which is costly, time-consuming, non-reversible and requires a skilled person in microbiology to implement it. We believe this approach has an impact beyond biofilms for biocatalysis. A similar strategy could be employed to identify candidate polymers for other microorganisms such as probiotics or yeasts, and develop new applications in food science, agriculture, bioremediation or health.”

The technology and polymer additives are the subject of a patent application by University of Birmingham Enterprise, which is now looking for business partners for licensing.

Dr. Fernandez-Trillo is now at the Universidade da Coruña, Spain.