3D printing, also known as additive manufacturing, is a technique for producing three-dimensional objects by depositing successive layers of material. While the effectiveness of the filter will be determined by the design and materials used, 3D printing can be a useful tool for prototyping and manufacturing custom filters.

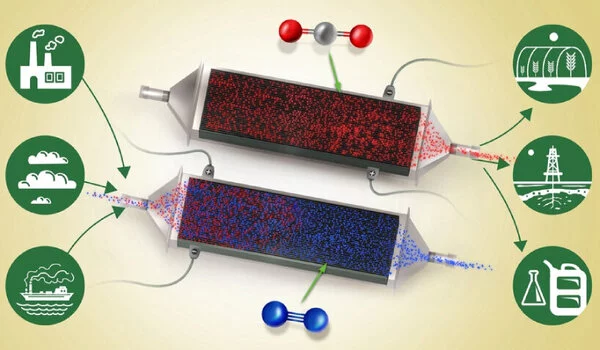

North Carolina State University researchers demonstrated that carbon dioxide capture filters can be made using 3D printing in a new study. They created a hydrogel material that can hold carbonic anhydrase, an enzyme that accelerates the reaction that converts carbon dioxide and water into bicarbonate.

According to the findings, which were published in the journal Gels, 3D printing could be a faster and more versatile method of creating filter designs.

“This manufacturing process, using 3D printing, makes everything faster and more precise,” said Jialong Shen, an assistant research professor of textile engineering, chemistry, and science at NC State. “You can make this functional material if you have access to a printer and raw materials.”

We formulated the hydrogel to be mechanically strong enough to be 3D printed as well as extruded into a continuous filament. Our design was inspired by our own cells, which have enzymes packed into compartmentalized spaces filled with a fluid. That kind of environment is ideal for assisting enzymes in their work.

Jialong Shen

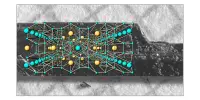

In the study, NC State Wilson College of Textiles researchers mixed a solution containing two different organic compounds – or the printing “ink” – and an enzyme called carbonic anhydrase. The researchers then used UV light to solidify the solution as they printed thread-like filaments of the hydrogel into a two-dimensional grid.

“We formulated the hydrogel to be mechanically strong enough to be 3D printed as well as extruded into a continuous filament,” Shen explained. “Our design was inspired by our own cells, which have enzymes packed into compartmentalized spaces filled with a fluid.” That kind of environment is ideal for assisting enzymes in their work.”

The researchers tested the properties of the material to understand how well it would bend and twist, and investigated the filter’s carbon capture performance. In a small-scale experiment, they found the filter captured 24% of the carbon dioxide in a gas mixture. While the capture rate is lower than what they’ve achieved in previous designs, the filter was less than an inch (2 centimeters) in diameter, and it could be made larger and in different modular shapes in order to stack them in a tall column. That could increase the capture efficiency, researchers said.

“We would need to make the filter larger in diameter or stack more filters on top of each other to get a higher capture rate,” Shen explained. “We don’t think that’s an issue; this was a small-scale initial test for ease of testing.”

The researchers also investigated the material’s filtration durability, discovering that it retained 52% of its initial carbon capture performance after more than 1,000 hours.

“This work is still in its early stages, but our findings indicate that there are new ways to make materials for carbon capture devices,” said Sonja Salmon, associate professor of textile engineering, chemistry, and science at NC State. “We’re offering a ray of hope for carbon capture.”