In electrical and electronics engineering, wetting current is the minimal electric current required to break through the surface layer resistance of a contact. It is a phrase used in electrical and electronic engineering, specifically in relation to relay and switch contacts. It is often much lower than the contact’s nominal maximum current rating. It refers to the minimal current required to run through a relay or switch to enable reliable switching, often known as “wetting” the contacts.

A thin film of oxidation, or an otherwise passivated layer, forms in most conditions, particularly those with high humidity, and, coupled with surface roughness, adds to contact resistance at an interface.

Providing a sufficient amount of wetting current is a crucial step in designing systems that use delicate switches with small contact pressure as sensor inputs. Failing to do this might result in switches remaining electrically “open” when pressed, due to contact oxidation.

Why it is Important

When relay or switch contacts are closed, a thin coating of insulating material may form owing to oxidation or contamination. This coating can inhibit proper electrical contact between the contacts, resulting in inconsistent operation or increased contact resistance.

The wetting current aids in the breakdown of this insulating coating, ensuring that when the contacts are closed, they form a reliable electrical connection. Without adequate wetting current, the contacts may fail to conduct effectively, resulting in high contact resistance, arcing, or even contact welding.

Importance in Relays

In relays, especially those used in low-level signal applications, wetting current is crucial to ensure that the contacts make a reliable connection when the relay is energized. Failure to achieve sufficient wetting current can result in signal distortion, loss of signal, or malfunction of the circuit the relay is controlling.

Factors Affecting Wetting Current

- Contact Material: Different contact materials have varying levels of susceptibility to oxidation and contamination, affecting the amount of wetting current needed.

- Contact Force: The force with which the contacts are pressed together can influence the wetting current. Higher contact force can help break through the insulating film more effectively.

- Contact Geometry: The shape and surface finish of the contacts can also influence wetting current requirements. Smooth, flat surfaces generally require less wetting current compared to rough or pitted surfaces.

- Environmental Factors: Factors like temperature, humidity, and the presence of contaminants in the environment can also affect the rate of oxidation and contamination, thereby influencing wetting current requirements.

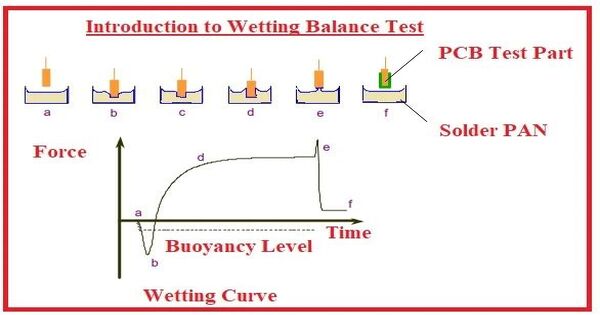

Testing Wetting Current

Wetting current can be measured using specialized equipment, which can determine the minimal current required to reliably switch the contacts. This testing is required throughout the design and production of relays and switches to assure their dependability under varying conditions.

In conclusion, wetting current is an important parameter in electrical and electronics engineering, particularly in the design and functioning of relays and switches. Understanding and regulating wetting currents can improve the reliability and durability of electrical contacts in a variety of applications.