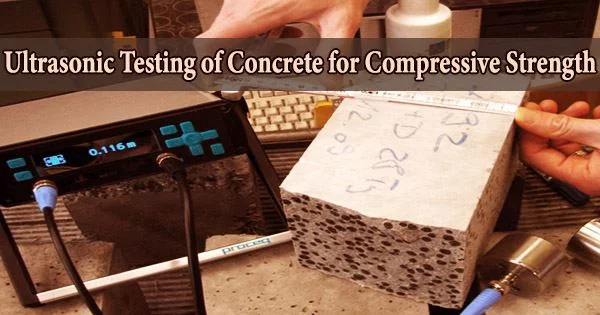

A non-destructive test to evaluate the homogeneity and integrity of concrete is ultrasonic testing, also known as an ultrasonic pulse velocity (UPV) test. By monitoring the speed and attenuation of an ultrasonic pulse travelling through the part being tested, UPV testing truly determines the integrity and quality of structural concrete or stone (up to 6 feet thick).

With this ultrasonic test on concrete, following can be assessed:

- Concrete’s strength is qualitatively assessed, graded at various points along structural members, and plotted.

- Any discontinuity in cross section like cracks, cover concrete delamination etc.

- Depth of surface cracks.

In comparison to high velocity areas, lesser velocity areas often have less density and strength. Tomographic images of flaws can be produced using data gathered along several test lines.

Ultrasonic Testing of Concrete

An electro-acoustical transducer kept in touch with one surface of the concrete member being tested generates an ultrasonic pulse of 50 to 54 kHz, and an identical transducer in contact with the surface at the other end measures the travel time, T.

With the path length L, (i.e. the distance between the two probes) and time of travel T, the pulse velocity (V=L/T) is calculated.

The pulse velocity increases with concrete’s elastic modulus, density, and integrity. The density and elastic characteristics of the material being examined influence the ultrasonic pulse velocity.

Though pulse velocity is related with crushing strength of concrete, yet no statistical correlation can be applied.

The pulse velocity in concrete may be influenced by:

- Path length

- Lateral dimension of the specimen tested

- Presence of reinforcement steel

- Moisture content of the concrete

The influence of path length will be negligible provided it is not less than 100mm when 20mm size aggregate is used or less than 150mm for 40mm size aggregate.

Pulse velocity will not be influenced by the shape of the specimen, provided its least lateral dimension (i.e. its dimension measured at right angles to the pulse path) is not less than the wavelength of the pulse vibrations.

For pulse of 50Hz frequency, this corresponds to a least lateral dimension of about 80mm. the velocity of pulses in steel bar is generally higher than they are in concrete. Because of this, measurements of pulse velocities near reinforcing steel may be excessive and unrepresentative of the concrete.

If the reinforcement runs in a direction that is perpendicular to the pulse route and the amount of steel is minimal in comparison to the length of the path, the influence of the reinforcement is often minimal. The pulse velocity may be slightly yet significantly influenced by the moisture content of the concrete.

In general, the velocity is increased with increased moisture content, the influence being more marked for lower quality concrete.

Measurement of pulse velocities at points on a regular grid on the surface of a concrete structure provides a reliable method of assessing the homogeneity of the concrete.

The size of the grid chosen will depend on the size of the structure and the amount of variability encountered.

Detection of Defects with Ultrasonic Test on Concrete

Any air-filled fracture or void that is directly between the transducers will block the direct ultrasonic beam if the void has a projected area that is greater than the area of the transducer faces because there is a negligible transmission of energy across the concrete-air interface.

The first pulse to arrive at the receiving transducer will have been directed around the periphery of the defect and the time will be longer than in similar concrete with no defect.

Estimating the depth of cracks

An estimate of the depth of a crack visible at the surface can be obtained by the transit times across the crack for two different arrangements of the transducers placed on the surface.

One suitable arrangement is one in which the transmitting and receiving transducers are placed on opposite sides of the crack and distant from it. Two values of X are chosen, one being twice that of the other, and the transmit times corresponding to these are measured.

An equation may be derived by assuming that the plane of the crack is perpendicular to the concrete surface and that the concrete in the vicinity of the crack is of reasonably uniform quality. It is important that the distance X be measured accurately and that very good coupling is developed between the transducers and the concrete surface. The method is valid provided the crack is not filled with water.

Procedure for Ultrasonic Pulse Velocity

Preparing for use: Before switching on the ‘V’ meter, the transducers should be connected to the sockets marked “TRAN” and ” REC”.

The ‘V’ meter may be operated with either:

- The internal battery,

- An external battery or

- The A.C line.

Set reference: A reference bar is provided to check the instrument zero. The pulse time for the bar is engraved on it. Apply a smear of grease to the transducer faces before placing it on the opposite ends of the bar. Adjust the ‘SET REF’ control until the reference bar transit time is obtained on the instrument read-out.

Range selection: For maximum accuracy, it is recommended that the 0.1 microsecond range be selected for path length upto 400mm.

Pulse velocity: Having determined the most suitable test points on the material to be tested, make careful measurement of the path length ‘L’. Apply couplant to the surfaces of the transducers and press it hard onto the surface of the material.

Do not move the transducers while a reading is being taken, as this can generate noise signals and errors in measurements. Continue holding the transducers onto the surface of the material until a consistent reading appears on the display, which is the time in microsecond for the ultrasonic pulse to travel the distance ‘L’.

The mean value of the display readings should be taken when the units digit hunts between two values.

Pulse velocity=(Path length/Travel time)

Separation of transducer leads: It is advisable to prevent the two transducer leads from coming into close contact with each other when the transit time measurements are being taken.

If this is not done, the receiver lead might pick-up unwanted signals from the transmitter lead and this would result in an incorrect display of the transit time.