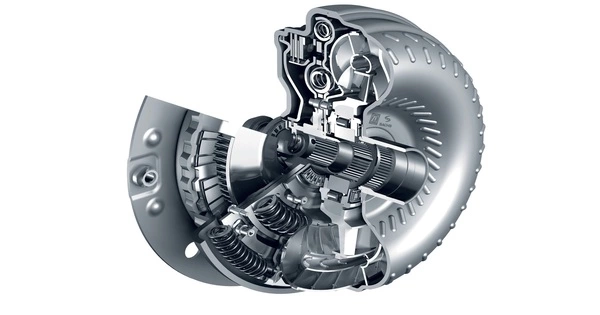

A torque converter is a form of fluid coupling that transfers rotating power from a prime mover to a rotating driven load. It is a form of fluid coupling used in automatic transmissions and other power transmission systems to transfer power from the engine to the transmission and then to the vehicle’s wheels. The torque converter transfers the power supply to the load in a vehicle with an automatic transmission.

It is commonly found between the engine’s flexplate and the transmission. The mechanical clutch is the analogous location in a manual transmission. It is a vital component in vehicles equipped with automatic gearboxes, and its major duty is to keep the engine running while the vehicle is stopped or moving slowly, such as when idling at a stop sign or crawling in heavy traffic.

A torque converter’s main feature is its ability to increase torque when the output rotational speed is so low that the fluid coming off the curved vanes of the turbine is deflected off the stator while it is locked against its one-way clutch, providing the equivalent of a reduction gear.

Here’s how a torque converter works:

- Fluid Coupling: The torque converter consists of two main parts – the impeller (driven by the engine) and the turbine (connected to the transmission input). These parts are submerged in transmission fluid. The impeller is connected to the engine’s crankshaft, so it rotates as the engine runs.

- Fluid Motion: When the engine is running, the impeller starts to spin and creates a flow of transmission fluid. This fluid flow is directed towards the turbine.

- Torque Multiplication: When the fluid from the impeller strikes the turbine, it causes it to spin. A torque converter’s main feature is its ability to double torque, allowing the engine to transfer more power to the transmission, especially in low-speed or high-load conditions. This torque multiplication is important for starting a large vehicle from a stop.

- Lockup: A lockup clutch in some modern torque converters can engage at greater speeds. When the lockup clutch is engaged, it mechanically links the impeller and the turbine, preventing fluid coupling. This improves overall transmission efficiency and minimizes heat generation, resulting in increased fuel efficiency.

- Smooth Transitions: The torque converter also enables for smooth gear transfers as the transmission shifts. The amount of torque multiplied when the transmission shifts gears can vary to provide smooth and continuous power delivery.

Overall, a torque converter in an automatic transmission has various benefits, including the ability to keep the engine running at idle, increased torque distribution at low speeds, and smooth gear changes. However, it does introduce some inefficiency due to the fluid coupling, which is why modern automatic transmissions often incorporate lockup clutches to minimize this inefficiency when driving at higher speeds.