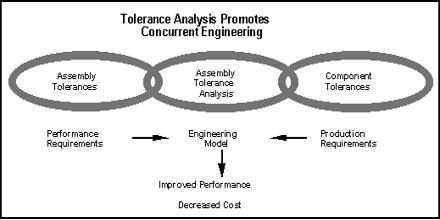

This article talks about Tolerance Analysis, which is a number of approaches used today in product design to understand how imperfections in parts as they are manufactured, and in assemblies as they are put together, affect the capability of a product to meet customer expectations. It is a way of understanding how sources of variation in part dimensions and assembly constraints propagate across parts and assemblies, and how that total variation affects the capability of a design to achieve its design requirements within the process capabilities of manufacturing organizations and supply chains. Tolerance Analysis methods may be used on other types of systems subject to accumulated variation, such as mechanical and electrical systems.

Tolerance Analysis