Screen-printing is a cost-effective method for producing large quantities of wearable electronics because it is a simple and efficient process that can be easily automated. It involves applying a conductive ink or paste through a stencil or mesh screen onto a substrate, such as fabric or plastic, to create electrical circuits and components. This method can reduce the cost of wearable electronics by reducing the need for expensive equipment and labor, and by allowing for the use of lower-cost materials. Additionally, screen-printing can be used to create flexible and stretchable electronics, which can improve the comfort and functionality of wearable devices.

A new study shows that electrodes can be created with only screen printing, resulting in a stretchable, durable circuit pattern that can be transferred to fabric and worn directly on human skin. These wearable electronics can be used to monitor patients’ health in hospitals or at home. Current commercial manufacturing of wearable electronics necessitates costly clean room processes. While some processes include screen printing, this new method relies entirely on screen printing, which can make manufacturing flexible, wearable electronics much easier and less expensive.

According to new research, the glittering, serpentine structures that power wearable electronics can be created using the same technology that is used to print rock concert t-shirts. The study, led by researchers at Washington State University, demonstrates that electrodes can be made using only screen printing, resulting in a stretchable, durable circuit pattern that can be transferred to fabric and worn directly on human skin. These wearable electronics can be used to monitor patients’ health in hospitals or at home.

We wanted to make flexible, wearable electronics in a way that is much easier, more convenient and lower cost. That’s why we focused on screen printing: it’s easy to use. It has a simple setup, and it is suitable for mass production.

Jong-Hoon Kim

“We wanted to make flexible, wearable electronics in a way that is much easier, more convenient and lower cost,” said corresponding author Jong-Hoon Kim, associate professor at the WSU Vancouver’s School of Engineering and Computer Science. “That’s why we focused on screen printing: it’s easy to use. It has a simple setup, and it is suitable for mass production.”

Current commercial manufacturing of wearable electronics necessitates costly clean room processes. While some companies use screen printing for parts of the process, this new method is entirely based on screen printing, which benefits manufacturers and, ultimately, consumers.

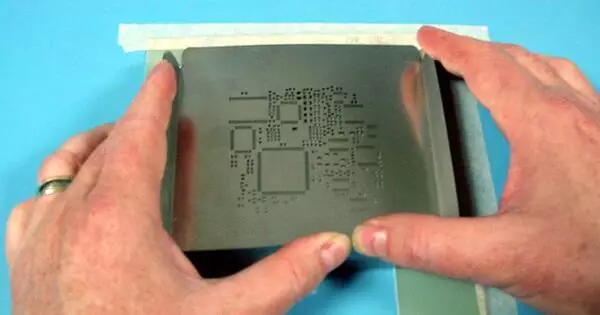

Kim and his colleagues detail the electrode screen-printing process in the study, which was published in the journal ACS Applied Materials and Interfaces, and show how the resulting electrodes can be used for electrocardiogram monitoring, also known as ECG.

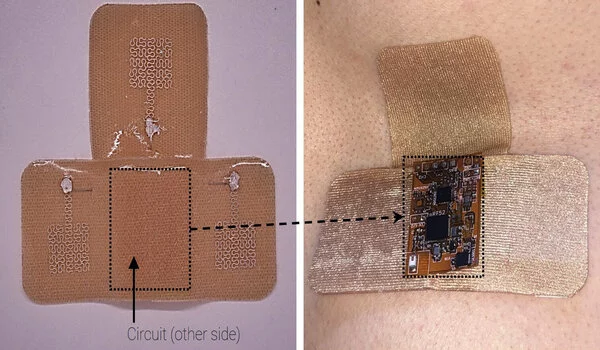

They used a multi-step process to layer polymer and metal inks to create snake-like structures of the electrode. While the resulting thin pattern appears delicate, the electrodes are not fragile. The study showed they could be stretched by 30% and bend to 180 degrees.

Multiple electrodes are printed on a pre-treated glass slide, allowing them to be easily peeled off and transferred to fabric or other material. After printing the electrodes, the researchers transferred them to an adhesive fabric, which was then worn directly on the skin by volunteers. The wireless electrodes accurately recorded heart and respiratory rates and transmitted the data to a mobile phone.

While this study focused on ECG monitoring, Kim explained that the screen-printing process can be used to create electrodes for a variety of applications, including those that serve similar functions to smartwatches or fitness trackers. Kim’s lab is currently working on expanding this technology to print different electrodes as well as entire electronic chips and, potentially, entire circuit boards.