The move to renewable energy necessitates effective techniques of storing significant volumes of electricity. Researchers at the Technical University of Munich (TUM) have devised a new approach that could significantly increase the lifespan of aqueous zinc-ion batteries. Instead of lasting a few thousand cycles, they could now withstand hundreds of thousands of charge and discharge cycles.

The key to this breakthrough is a unique protective layer applied to the batteries’ zinc anodes. This layer addresses earlier difficulties, such as the creation of needle-like zinc structures called zinc dendrites, as well as undesired chemical side reactions that cause hydrogen generation and corrosion.

The research team, led by Prof. Roland A. Fischer, Chair of Inorganic and Metal-Organic Chemistry at the TUM School of Natural Sciences, uses a unique material for this purpose: a porous organic polymer called TpBD-2F. This material forms a stable, ultra-thin, and highly ordered film on the zinc anode, allowing zinc ions to flow efficiently through nano-channels while keeping water away from the anode.

Zinc-ion batteries with this new protective layer could replace lithium-ion batteries in large-scale energy storage applications, such as in combination with solar or wind power plants. They last longer, are safer, and zinc is both cheaper and more readily available than lithium.

Da Lei

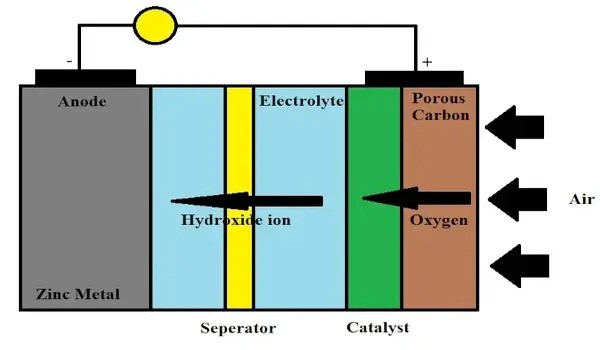

Extending the lifespan of zinc-based batteries is an area of active research, as zinc is a promising alternative to more expensive or toxic materials like lithium. Zinc batteries, particularly zinc-air and zinc-ion batteries, offer advantages such as low cost, high safety, and environmental friendliness. However, they face challenges like poor cycle life and issues with dendrite formation (for zinc-ion batteries) or capacity degradation (for zinc-air batteries). Researchers have made significant strides in improving the longevity of these batteries by addressing these challenges.

Zinc Batteries as a Cost-Effective Alternative to Lithium-Ion Batteries

Da Lei, Ph.D. student and lead author of the research published in Advanced Energy Materials, explains: “Zinc-ion batteries with this new protective layer could replace lithium-ion batteries in large-scale energy storage applications, such as in combination with solar or wind power plants. They last longer, are safer, and zinc is both cheaper and more readily available than lithium.” While lithium remains the first choice for mobile applications like electric vehicles and portable devices, its higher costs and environmental impact make it less attractive for large-scale energy storage.

Prof. Roland A. Fischer adds: “This is a genuinely outstanding research outcome. We demonstrated that Da Lei’s chemical technique is not only effective, but also manageable. As basic researchers, we are particularly interested in new scientific concepts, and we have uncovered one. We’ve already created a first prototype in the form of a button cell. I see no reason why our findings can’t be applied to broader applications. Now it’s up to engineers to take up the idea and create suitable manufacturing techniques.”