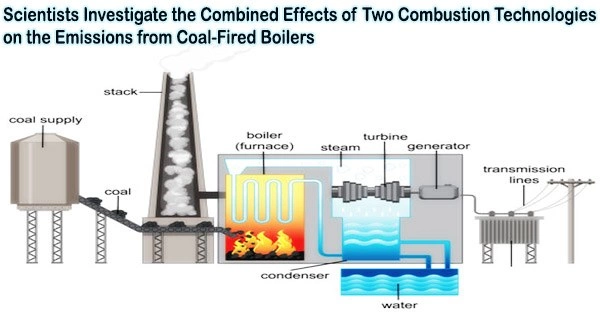

To meet the demand for electricity generation around the world, coal-fired power stations have long been in operation. On this front, it goes without saying that there are environmental and human health issues to be addressed. Even though there are constant efforts to switch to renewable energy sources, coal-fired power stations might still be there for a while.

In light of this, it is important to investigate ways to increase the efficiency of these coal-fired boilers while reducing their negative effects on the environment, specifically their production of acid rain, greenhouse gas emissions, and photochemical smog.

Various combustion techniques, including air a staging and swirl flow, have been suggested to achieve this. Uncertainty persists over the effectiveness of these devices in minimizing pollution emissions while maximizing burnout performance.

Now, in a recent study made available online on 31st December 2022 and to be published in Volume 268, Issue 1 of the journal Energy on 1st April 2023, an international team of researchers led by Prof. Gyungmin Choi of Pusan National University, Korea analyzed the effectiveness of combining swirl flow and air staging in improving the combustion performance and reducing pollution.

“The exhaust tube vortex (ETV) structure accompanying the swirl flow improves flame stability and combustion performance, but has the disadvantage of generating a large amount of NOx emissions. In contrast, air staging technology creates a fuel-rich environment in the primary combustion zone, which has a positive effect on NOx reduction but negatively affects combustion performance,” explains Prof. Choi. “Therefore, if these two technologies are appropriately combined and applied in real life, a synergistic effect that reduces the emission of air pollutants as well as improves combustion performance can be expected.”

As a result, the team studied the combined effects of various swirl configurations and air staging within a 16-kWth retrofitted down-fired pulverized coal boiler using both simulations and experiments.

The exhaust tube vortex (ETV) structure accompanying the swirl flow improves flame stability and combustion performance, but has the disadvantage of generating a large amount of NOx emissions. In contrast, air staging technology creates a fuel-rich environment in the primary combustion zone, which has a positive effect on NOx reduction but negatively affects combustion performance.

Professor Gyungmin Choi

The swirl burner, the boiler, and the exhaust pipe made up the coal boiler’s three parts. Staged air was split into two sides and injected tangentially into the boiler for staged combustion.

Liquified petroleum (LPG) gas was used for preheating and flame stabilization. The temperature was measured using thermocouples for each setting, and the staged-air and LPG flow rates were controlled. A multi-gas analyzer was also used to measure the quantity of gas-phase species.

To determine which of the two swirl configurations, co-swirling and counter-swirling flames, is more advantageous in terms of lowering pollutant emissions, air staging with the two swirl configurations was tested.

Due to the establishment of the inner circulation zone and the ETV two crucial elements for optimizing the design of coal-fired boilers the coal particles in the co-swirling burner, where the air and fuel cycled in the same sense, were dispersed uniformly.

The team also noticed that the co-swirling setup had an even burnout zone, which guaranteed complete fuel combustion and decreased gas species emissions. Additionally, it made it easier for more chemical energy to be converted into thermal energy, increasing the combustion efficiency.

Co-swirling was preferable to counter-swirling because counter-swirling burners had uneven coal particle dispersion, uneven burnout, and increased NOx emissions. Additionally, the team showed that air staging technology reduced the environmental costs from $0.003 to $0.015 per day.

Overall, the knowledge gained from this study could be very helpful in addressing the environmental issues and health risks associated with coal-fired power plants.

“We have identified and studied the structure and flame of the ETV for the first time, and will continue researching and striving to utilize it in the combustion-based industry,” concludes an optimistic Prof. Choi.