Although hydrogen is abundant on Earth, it is usually always found as part of another component, such as water (H2O) or methane (CH4), and it must be split into pure hydrogen (H2) for use in fuel cell electric cars. Through an electrochemical mechanism, hydrogen fuel interacts with oxygen from the air in a fuel cell, producing power and water.

According to a study conducted by scientists at the National Renewable Energy Laboratory, perovskite materials have the potential to play a key role in a process for producing hydrogen in a renewable manner (NREL).

Hydrogen has developed as an essential carrier for storing renewable energy, as a substitute for fossil fuels used in transportation, ammonia manufacturing, and other industrial applications. The ability to accomplish the Department of Energy’s Hydrogen Energy Earthshot — a recently stated target of reducing the cost of clean hydrogen by 80 percent to $1 per kilogram in a decade — is critical to the successful use of hydrogen as a fuel.

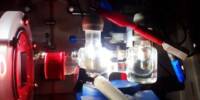

The NREL scientists investigated a new water-splitting technology known as solar thermochemical hydrogen (STCH) production, which has the potential to be more energy efficient than the regularly used electrolysis approach. To split water into hydrogen and oxygen, electrolysis requires power. STCH relies on a two-step chemical process in which metal oxides are exposed to temperatures greater than 1,400 degrees Celsius and then re-oxidized with steam at lower temperatures to produce hydrogen.

It’s certainly a very challenging field, and it has a lot of research questions still unanswered, mainly on the materials perspective. System and Technoeconomic Analysis of Solar Thermochemical Hydrogen Production.

Zhiwen Ma

“It’s certainly a very challenging field, and it has a lot of research questions still unanswered, mainly on the materials perspective,” said Zhiwen Ma, a senior engineer at NREL and lead author of a new paper, “System and Technoeconomic Analysis of Solar Thermochemical Hydrogen Production,” which appears in the journal Renewable Energy. His co-authors, all from NREL, are Patrick Davenport and Genevieve Saur.

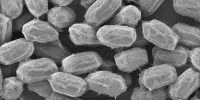

The report adds to existing materials discovery research by examining system-level design and techno-economic analysis for incorporating potential materials into a solar-fuel platform and helping the Department of Energy’s HydroGEN initiative. Machine learning, defect calculations, and experimental work were used in the HydroGEN initiative to generate novel perovskite materials. The researchers must identify perovskites that can withstand the high temperatures while meeting performance objectives.

This paper is part of a portfolio of techno-economic analyses focusing on hydrogen generation methods, each with its own set of benefits and drawbacks. Electrolysis, for example, is commercially accessible, and the requisite electricity can be generated using photovoltaics (PV). However, the PV cells utilized only catch a portion of the sunlight spectrum. STCH makes use of the entire spectrum. STCH is able to create the chemical reaction due to the concentrated solar thermal power.

Hydrogen generation is critical in any industrialized culture since hydrogen is required for many critical chemical reactions. In 2020, around 87 million tons of hydrogen were produced worldwide for a variety of uses, including oil refining, the manufacturing of ammonia (NH3) (through the Haber process) and methanol (CH3OH) (by carbon monoxide [CO] reduction), and as a transportation fuel. In 2017, the hydrogen generation industry was anticipated to be worth $115.25 billion.

There are numerous problems in developing an infrastructure for hydrogen distribution and delivery to thousands of future individual fuelling stations. Because hydrogen has less energy per unit volume than all other fuels, transporting, storing, and distributing it to the point of consumption costs more per gasoline gallon equivalent. The initial capital expenses of constructing a new hydrogen pipeline network are considerable, and the characteristics of hydrogen bring unique problems to pipeline materials and compressor design. However, because hydrogen can be made from a wide range of resources, regional or even local hydrogen production can maximize the use of local resources while reducing distribution issues.

The experts stated that active research to identify the optimal materials for the STCH process is vital to the success of this method of hydrogen production. “The material has not necessarily been discovered,” Saur explained, “but the purpose of our analysis is to establish some bounds for where we believe the costs will be if the materials match some of the aims and expectations that the research community expects.”