Now RMG sector in Bangladesh developed day by day. Our garments products are very good in quality and for this reason the international market demand our products is very much high. Although worker salary range, worst environment and political situation create problem. For these cause in future the problems faces in regular basis. In the report analysis focus on develop the relation with ultimate Buyer. The focus will be long term relation and administrative and Production Procedure how to develop.

Introduction

ALFA KNIT FASHION LTD.. is a prominent developing knit garments company in Bangladesh. It started its journey from 2007 to complete knit garments industry with knit sewing machines, knit circular machines & 2 nos. of computerized embroidery machine at Shafipur, Gazipur, Bangladesh with 25000 sft. Floor area. Its management is a strong and highly qualified Personnel. The target of the company is to develop as a most prestigious garments company in Bangladesh. It is trying to carry on all or any of the Export of manufacturing any fabrics readymade garments of all sizes, grades, kinds and descriptions for the buyers abroad and inland.

To buy, sell, import, export, prepare and deal in merchandise, commodities and articles of all kinds and generally to carry on Export as merchants, importers and exporters of all goods including textiles, garments and allied materials of all sorts. To carry on Export of all sorts of garments and textile and sell locally and export to foreign countries and create local as well as foreign markets and appoint agents, commission agents and establish sales office, showrooms both at home and abroad for the expansion of markets of the products of the company.

Rationale of the Study

RMG sector is one of the most progressing sectors in Bangladesh. Now-a-days the Export of RMG sector grows rapidly in our country. Most of the Export people of our country are very much interested in this new Export sector. We know that our garments products are very good in quality and for this reason the international market demand our products. The other reason that’s why our products are very much appreciated in the world market that is its low cost. We know that the labors cost of our country is very cheaper than the other neighbors countries, so the Export people of our country can delivery a product at a lower price than the competitors other countries. Also this is a very profitable Export for the Export people and all of these reasons the future of the RMG sector in our country is very bright.

But there are some problems also stand in this profitable sector. If our country want do better in this sector its might has to solve those problems immediately. It is necessary that if our government and also the people who are involve in RMG sector make together and protect the problems as soon as possible if we want to alive this profitable sectors. Because today’s market is very competitive market. If we are late then you are sure that the other can take your position very quickly.

Scope of the Study:

The field of study has been for the first portion the Garments division activities. For the RMG sector analysis and make sure the Garments sector development with achieve Export from abroad.

Objective of the Report:

Broad Objectives:

The study was conducted to make an analysis of the RMG sector of Bangladesh. This report shows the today’s RMG situation in our country. How much it doing in present day and in the recent future and also the problems it faces in regular basis.

Specific Objectives:

The specific objective of the report is to know in details about the delinquent problems and prospects of the Bangladesh RMG sector. The Project has been directed by the following specific Objective:

- Develop the relation with ultimate Buyer. The focus will be long term

- Assessment the competitive the Global Market.

- Administrative and Production Procedure how to develop.

- Positive and negative atmosphere in RMG sector and what is the real solution.

- Quality assurance as per Buyer requirement. A good quality makes a good Export.

- Lastly, Influence the Buyer to our RMG Export.

Methodology

Area of Investigation:

I would use both primary and secondary data. In case of primary data I will refer to direct interviewing of the managements of the F8 FASION LTD Ltd. But in generally I use mostly the secondary data.

Source of Information:

Primary:

The primary data are collected from the experts who are involving with the RMG sector in a long period help me a lot.

Secondary:

The secondary data of the study are based on some of the important websites which are related with RMG sector. I am also using some journals and some books which are related mostly the RMG sector.

Analysis and Interpretation of the Data

In Bangladesh, agriculture has been the backbone of economy and chief source of income for the people. Government wants to decrease poverty by getting highest productivity from agriculture and achieve self-reliance in food production. Apart from agriculture, the country is much concerned about the growth of export division. Bangladesh have accelerated and changed her exports substantially from time to time. After Bangladesh came into being, jute and tea were the most export-oriented industries. But with the continual perils of flood, failing jute fiber prices and a considerable decline in world demand, the role of the jute sector to the country’s economy has deteriorated. After that, focus has been shifted to the function of production sector, especially in garment industry.

The shift from a rural, agrarian economy to an urban, industrial economy is integral to the process of economic development. Although policymakers in the least developed countries (LDCs) have, at various times, attempted to make agriculture the primary engine of economic growth and employment generation, this approach has not worked, not least because of the contributions of the Green Revolution, which has had the dual effect of increasing agricultural productivity in the LDCs and displacing the rural labor force at the same time. Led by the example of the East Asian economies, most LDCs now accept the need for greater industrialization as the fastest path to economic growth. In particular, countries such as Japan, Taiwan and South Korea have demonstrated that an export-oriented industrial strategy can not only raise per capita income and living standards in a relatively short time; it can also play a vital role in modernizing the economy and integrating it with the global economic system.

Bangladesh, one of the archetypal LDCs, has also been following the same route for the last 30 years. Once derided as a “basket-case” by Henry Kissinger (The Economist, 1996), the country stumbled across an economic opportunity in the late 1970s. New rules had come to govern the international trade in textiles and apparel, allowing low-cost suppliers to gain a foothold in American and European markets. Assisted by foreign partners, and largely unaided by the government, entrepreneurs seized the opportunity and exploited it to the fullest. Over a period of 30 years, the garments export sector has grown into a $6 billion industry that employs over a million people. In the process, it has boosted the overall economic growth of the country and raised the viability of other export-oriented sectors.

This essay analyzes the processes by which global trading rules came to help out a poor country like Bangladesh. It demonstrates the impact of the rule changes on the garments sector, and the response of the sector to multiple challenges and obstacles. It also discusses what steps Bangladesh should take in order to deal with the full liberalization of the international garments trade, which occurred in January 2005 and which could potentially threaten the country’s growth prospects. Finally, it details some of the recent developments that have occurred since liberalization took effect.

The tremendous success of readymade garment exports from Bangladesh over the last two decades has surpassed the most optimistic expectations. Today the apparel export sector is a multi-billion-dollar manufacturing and export industry in the country. The overall impact of the readymade garment exports is certainly one of the most significant social and economic developments in contemporary Bangladesh. With over one and a half million women workers employed in semi-skilled and skilled jobs producing clothing for exports, the development of the apparel export industry has had far-reaching implications for the society and economy of Bangladesh.

Garment Industry of Bangladesh

The RMG industry of Bangladesh has expanded dramatically over the last three decades. Traditionally, the jute industry dominated the industrial sector of the country until the 1970s. Since the early 1980s, the RMG industry has emerged as an important player in the economy of the country and has gradually replaced the jute industry. In Bangladesh the RMG sector is one of the most profitable sectors in recent years.

For this reason most of the people of our country are very much interested about this sector. As a result in now days in our country there are some successful RMG are introduce which can compute the foreign buying house in international market. They already bit some of the successful RMG in another country. It is a good sign for Bangladesh that The Fashion Designing profession has recently emerged as one of the most demandable careers among the youth. These young folks have their own creative style of dressing and belief in setting a trend rather than following a trend set by others. A career in fashion design not only involves meeting glamorous people and interacting with rich and famous but also gives an impetus to the creative flair of the people who possess a sense of style. But still Bangladesh is struggling to establish a standard in fashion design for international market.

The future of the Bangladeshi textile production lies in the development of high-value-added products, suitable for long-term export markets and for the local market in short-term. In order to develop such products, Bangladesh needs strengthening of its design potential. This should mainly be done through training Bangladeshi designers with the help of the foreign designers. This way, product development and training in the workplace will be combined, giving both short term and longer-term effects. This is a large sector supporting the newly established schools through training the designers for this industry should be considered as important investment for market sustainability.

For Bangladesh, the readymade garment export industry has been the proverbial goose that lays the golden eggs for over fifteen years now. The sector now dominates the modern economy in export earnings, secondary impact and employment generated. The events in 1998 serve to highlight the vulnerability of this industry to both internal and external shocks on the demand and supply side. Given the dominance of the sector in the overall modern economy of Bangladesh, this vulnerability should be a matter of some concern to the policymakers in Bangladesh. Although in gross terms the sector’s contributions to the country’s export earnings is around 74 percent, in net terms the share would be much less partially because the backward linkages in textile have been slow to develop. The dependence on a single sector, no matter how resilient or sturdy that sector is, is a matter of policy concern. We believe the policymakers in Bangladesh should work to reduce this dependence by moving quickly to develop the other export industries using the lessons learned from the success of apparel exports. Support for the apparel sector should not be reduced. In fact, another way to reduce the vulnerability is to diversify the product and the market mix. It is heartening to observe that the knit products are rapidly gaining share in overall garment exports as these products are sold in quota-free markets and reflect the strength of Bangladeshi producers in the fully competitive global apparel markets.

Preliminary data and informal evidence indicate that this sector seems to have weathered the devastating floods relatively well. The industry is one hundred percent export-oriented and therefore insulated from domestic demand shocks; however, it remains vulnerable to domestic supply shocks and the smooth functioning of the banking, transportation and other forward and backward linkage sectors of the economy. The Dhaka-Chittagong road remains the main transportation link connecting the production units, mostly situated in and around Dhaka and the port in Chittagong, where the raw material and the finished products are shipped in and out. Despite increased dependence on air transportation, trucks remain the main vehicles for transporting raw materials and finished products for Bangladesh garment exports. The floods disrupted the normal flow of traffic on this road.

Eventually, this road link was completely severed for several days when large sections of the road went under water for a few weeks during the latter phase of the floods. This delinking of the road connection between Dhaka and the port in Chittagong was as serious a threat as one can imagine for the garment exporters. The industry responded by calling upon the Bangladesh navy to help with trawlers and renting a plane from Thai Air that was used to directly fly garment consignments from the Dhaka airport to the Chittagong airport several times a day.

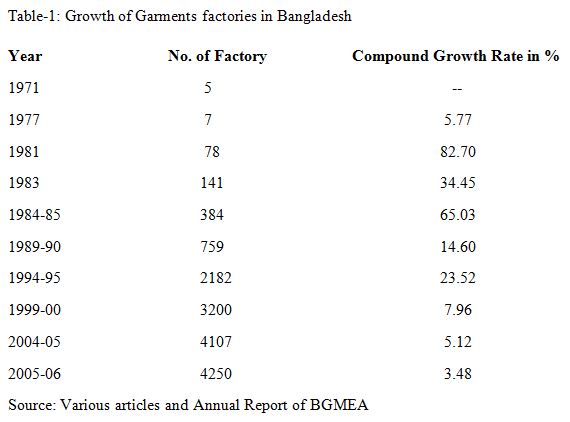

The Table-01 shows that the growth was very slow till 1977 and got momentum from 1977 to 2005-06 in terms of number of industry. But the compound growth rate was highest till 1981 and the rate was very good during 1989-90 to 1994-95 and thereafter i.e. 1994-95 to 2004-05, the industrial growth has been declined though the numbers of industries have been increased. The capacity as well as number of equipments is very good indicator to examine the actual position of the garment industry as well as size of the industry. In such a context, the following Table deals in this regard.

Table-2: Garments Industries with number of Machine

Year Garment Industry having No. of Machine Total

Up to 100 101 – 200 201 and over

2004 2253 (64) 726 (21) 531 (15) 3510 (100)

2005 2275 (62) 773 (21) 620 (17) 3668 (100)

Source: Annual Report of BGMEA. Figures in parentheses indicate percentage

From the Table 02 it is found that more than half of the total garment industries in Bangladesh have the number of machines upto 100 or less than 100 and very few industries have the machine more than 200. It indicates that the small scale industries have been dominated in the garment sector.

Currently, there are more than 4,000 RMG firms in Bangladesh. More than 95 per cent of those firms are locally owned with the exception of a few foreign firms located in export processing zones (Gonzales, 2002). The RMG firms are located mainly in three main cities: the capital city Dhaka, the port city Chittagong and the industrial city Narayangonj. Bangladesh RMG firms vary in size. Based on Bangladesh Garment Manufacturers and Exporters Association (BGMEA) data, Mainuddin (2000) found that in 1997 more than 75 per cent of the firms employed a maximum of 400 employees each. Garment companies in Bangladesh form formal or informal groups. The grouping helps to share manufacturing activities, to diversify risks; horizontal as well as vertical coordination can be easily found in such group activities.

Ready-made garments manufactured in Bangladesh are divided mainly into two broad categories: woven and knit products. Shirts, T-shirts and trousers are the main woven products and undergarments, socks, stockings, T-shirts, sweaters and other casual and soft garments are the main knit products. Woven garment products still dominate the garment export earnings of the country. The share of knit garment products has been increasing since the early 1990s; such products currently account for more than 40 per cent of the country’s total RMG export earnings. Although various types of garments are manufactured in the country, only a few categories, such as shirts, T-shirts, trousers, jackets and sweaters, constitute the major production-share (BGMEA website; and Nath, 2001). Economies of scale for large-scale production and export-quota holdings in the corresponding categories are the principal reasons for such a narrow product concentration.

Contribution of the RMG Industry

Garments Industry occupies a unique position in the Bangladesh economy. It is the largest exporting industry in Bangladesh, which experienced phenomenal growth during last two decades. By taking advantage of an insulated market under the provision of Multi Fibre Agreement (MFA) of GATT, it attained a high profile in terms of foreign exchange earnings, exports, industrialization and contribution to GDP within a short span of time. The industry plays a key role in employment generation and in the provision of income to the poor. Nearly two million workers one directly and more than ten million inhabitants are indirectly associated with the industry. The sector has also played a significant role in the socio-economic development of the country. In such a context, the trend and growth of garments export and its contribution to total exports and GDP has been examined the following table shows the position.

Table-3: Growth and Trend of Garments Exports, and contribution to GDP (Amounts in Million USD)

Year Garment Export Total Export Share to Total Export Share to GDP in % in %

1984-85 116 934 12.42 —

1989-90 624 (40) 1924 (16) 32.43 (21) —

1994-95 2228 (29) 3473 (13) 64.15 (15) 5.87

1999-00 4349 (14) 5752 (11) 75.61 (3) 9.23 (9)

2004-05 6418 (8) 8655 (9) 74.15 (-1) 10.63 (3)

2005-06 7901 (23) 10526 (22) 75.06 (1) 12.64 (2)

Source: Economic Review of Bangladesh, BGMEA and Computation made by author. Figures in parentheses indicate compound growth rates (CGR) for the respective periods.

It is revealed from the Table 03 that the value of garment exports, share of garments export to total exports and contribution to GDP have been increased significantly during the period from 1984-85 to 2005-06. The total garments export in 2005-06 is more than 68 times compared to garments exports in 1984-85 whereas total country’s export for the same period has increased by 11 times. In terms of GDP, contribution of garments export is significant; it reaches 12.64 percent of GDP in 2005-06 which was only 5.87 percent in 1989-90. It is a clear indication of the contribution to the overall economy. It also plays a pivotal role to promote the development of linkage small scale industries. For instance, manufacturing of intermediate product such as dyeing, printing, zippers, labels has began to take a foothold on limited scale and is expected to grow significantly. Moreover it has helped the Export of basling, insurance, shipping, hotel, tourism and transportation. The sector also has created jobs for about two million people of which 70 percent are women who mostly come from rural areas. The sector opened up employment opportunities for many more individuals through direct and indirect economic activities, which eventually helps the country’s social development, woman empowerment and poverty alleviation. In such a way the economy of Bangladesh is getting favorably contribution from this industry.

One of the key advantages of the RMG industry is its cheap labor force, which provides a competitive edge over its competitors. The sector has created jobs for about two million people of which 70 percent are women who mostly come from rural areas. The sector opened up employment opportunities for many more individuals through direct and indirect economic activities, which eventually helps the country’s social development, woman empowerment and poverty alleviation.

Garments Product Portfolio and its Diversification

The specific character of products and level of industrial development indeed determines its variance of product diversification. In such a context, the product mix, product line as well as product diversification are very important strategies for any industry to develop its market by meeting the present market requirements. For the garments industry it is also very important because product diversification will call for developing capability for product development and product design especially in response to fast changes in fashion. The growth pattern of garments export can be categorized into two distinct phases. During the initial phase it was the woven category. Second phase is the emergence of knitwear products. On the other hand, an analysis of the product mix of the garments industry revealed that so far Bangladesh has been able to export very limited categories of products. In such a context, an attempt has been made to examine the growth and trend of product portfolio or categories of products exported from Bangladesh. The following Table deal with the value and quantity of different garment products export including their growth pattern from 1992-93 to 2005-06

Table-5: Pattern of Export Performance of Different Garments Products (Amount in Million USD)

Year Shirts Trousers Jackets T-Shirts Sweaters Others

1994-95 791 (36) 101 (5) 147 (7) 232 (10) N/A N/A

1999-00 1021 (23) 484 (11) 440 (10) 564 (13) 325 (8) 1515 (35)

2004-05 1053 (16) 1668 (26) 430 (7) 1350 (21) 893 (14) 1024 (16)

2005-06 1057 (13) 2165 (27) 390 (5) 1782 (23) 1044 (13) 1463 (19)

CGR (%) 2.67 32.13 9.28 20.36 21.47 —

Source: Garments Export Data, BGMEA and Export Promotion Bureau-EPB. Figures in parentheses indicate the share in percentage.CGR stands for Compound Growth Rate.

From the Table 05, it is evident that the highest compound growth rate has been found in Trousers 32.13 percent, followed by T-shirts 20.36 percent, Jackets 9.28 percent, and T-Shirt 2.67 percent respectively during the period of 1994-95 to 2005-06. The rate of Sweater is also significant during the period of 1999-2000 to 2005-06. It is observed that the share of Trousers and T-Shirt in the total garment export is increasing. On the other hand, the share of shirts and Jackets is declining trend. The Figures indicate that Bangladesh has concentrated in the production and export of Trousers, T-Shirts and Sweater. This mean’s that there is a scope and actually need for structural change in product mix.

Exporting Condition of Garments Industry

The Ready-Made Garments (RMG) industry occupies a unique position in the Bangladesh economy. It is the largest exporting industry in Bangladesh, which experienced phenomenal growth during the last 20 years. By taking advantage of an insulated market under the provision of Multi Fibre Agreement (MFA) of GATT, it attained a high profile in terms of foreign exchange earnings, exports, industrialization and contribution to GDP within a short span of time. The industry plays a key role in employment generation and in the provision of income to the poor. Nearly two million workers are directly and more than ten million inhabitants are indirectly associated with the industry. Over the past twenty years, the number of manufacturing units has grown from 180 to over 3600. The sector has also played a significant role in the socio-economic development of the country.

The Agreement on Textile and Clothing (ATC) introduced in 1994, aimed at bringing textiles and clothing within the domain of WTO rules by abolishing all quotas by the end of 2004. It provides an adjustment period of 10 years, so that countries affected by the MFA could take the necessary steps to adjust to the new trading environment. Liberalization of trade following the Uruguay Round agreement presents opportunities as well as challenges for a developing country like Bangladesh in RMG sector. In the Post-Uruguay Round period, traditional instruments of trade policy such as tariffs, quotas, and subsidies will become less feasible and less relevant. In a liberalized trade regime, competition among textiles and clothing exporting countries is likely to become intense. The objective of this paper is to identify the prospects of RMG industry after the MFA phase out by analyzing the current scenario along with different policy measures and the available options in order to be more competitive in the new regime.

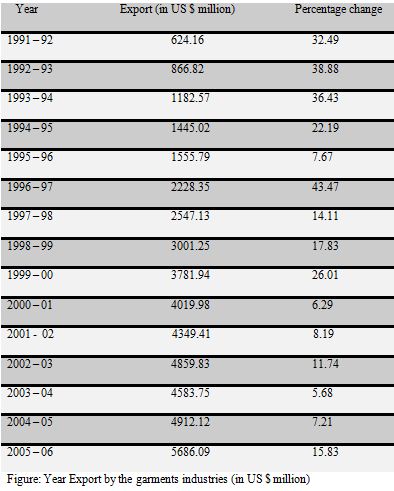

The export made by Garments Industries of Bangladesh is improving year after year except some of the year. Strike, layout, shutdown of company, political problem, economic problem, inflation etc. are the prime cause of decreasing export in this important sector. But above it, Readymade Garments Industries is the leading sector in export sector.

Position of Bangladesh is exporting product in USA is not very satisfactory but this situation is better than any other condition of the previous time. But if our Government take some essential law and break out the wall of biasness then the position of Bangladesh in Garments sector would be hope to better.

Findings of Study

The international trade of textiles is highly competitive. Skill, design and quality are essential. But, equally important is the need to assess national and international demands and integrate them into the production process. There is no doubt that very few of the Bangladeshi designers know the international markets. There is a unison cry in Bangladesh saying that they need help from foreign designers to make their products marketable internationally. This is even more the case if the products are going to be developed into high-value niche products.

There are very few designers in the garment industry or in crafts with a degree in design. The ones that do have a design education are educated abroad – many in India and some in the West. Some of the designers working in the craft Exportes have an education from Institute of Fine Arts, University of Dhaka. Although this educational background in combination with experience from the craft Exportes, in many cases seem to work well, some say that a lot of people in the trade do not understand the difference between an artist and a designer, “Design is planning step by step and the artists do not know how to do that.” Others say that the creativity exists, but the understanding of the market is lacking. Designers, of whatever level of training, who can work for a domestic market, are undoubtedly in advantageous position.

The practice of trial and error is certainly of value and a lot less costly. The exposure to shifting trends allows a designer to develop a sense of the market and, in time, the ability to predict market trends and design with confidence to meet the demands. If a designer is required to design for a foreign rather than local market, then certain skills are not able to develop in a full and relevant way.

The problem is the same for designers either in industry or crafts. In many respects, they are being asked to design for ‘virtual’ situations only. After all, very few of the designers in these Exportes will ever get the chance to visit the markets they design for, let alone be able to spend time enough in them to really develop an understanding of the nuances of a situation. Accordingly, western designers can best help with the designs for the export markets of Bangladesh. However, as the local market is changing rapidly due to increased buying power of internationally-oriented middle class, the products designed for the export market may very well have a future in the local market.

The garment industry of Bangladesh has been the key export division and a main source of foreign exchange for the last 25 years. National labor laws do not apply in the EPZs, leaving BEPZA in full control over work conditions, wages and benefits. Garment factories in Bangladesh provide employment to 40 percent of industrial workers. But without the proper laws the worker are demanding their various wants and as a result conflict is began with the industry.

Low working salary is another vital fact which makes the labor conflict. Worker made strike, layout to capture their demand. Some time bonus and the overtime salary are the important cause of crisis. Insufficient government policy about this sector is a great problem in Garments Company.

There are some other problems which are associated with this sector. Those are- lack of marketing tactics, absence of easily on-hand middle management, a small number of manufacturing methods, lack of training organizations for industrial workers, supervisors and managers, autocratic approach of nearly all the investors, fewer process units for textiles and garments, sluggish backward or forward blending procedure, incompetent ports, entry/exit complicated and loading/unloading takes much time, time-consuming custom clearance etc.

There are several findings, which will explain the reasons why Bangladesh is struggling in international market:

Scarcity of Raw Materials:

There is no alternative of ample supply of raw materials in order to become self sufficient in any industry. The raw materials of the garment industry of Bangladesh is foreign dependent. Bangladesh has to import raw materials of garments from abroad in order to process it in Bangladesh. About 70% of garment export income has to be spent for the raw materials. Moreover, the export and import policy of Bangladesh is very weak. So, the scarcity of raw materials for the garment industry’ in Bangladesh is a great threat.

Fail to delivery the product on the date:

This is one of the most common problems for almost all the RMG in the world to delivery the products on the date and in our country its percent is high. Delivery the products on the date is very important for the RMG Export the buyer who give the order have their own Export strategy and when miss the delivery on the specific date their work schedule will hamper and it makes very bad impression for RMG company and also the country. In our country it is happen mostly because of many unusual factors like -hortal, labor strike, vehicle strike etc. and in our country we see those factors a lot. So these are very big problems for the RMG Export.

Restriction of tariff and cotta system:

Sometimes tariff and cotta system create some problems for our country. Because our country is a developing country and the RMG sector is a new sector. In the cotta system we can delivery just a certain quantity of garment products. So if we wish to produce more or we have the capability to produce more garments products it is not possible because we can’t sell our product in the international market because of the cotta system.

Increase the price of raw material:

We know that the prices of raw materials are increasing day by day in inside the country and also the international market. Because of the increasing of the price of raw materials the cost of production of the garments products are also increases. So if the production cost increases the price of the finish goods also increase and because of that we can’t offer the buyer at a lower price in any garments products and for this reason there is a chance for our Garments companies to loose their position in the international market and in this situation any body can take the chance to hold their place.

Security of foreign buyer:

This is very important for the Garments Export to ensure the security for the foreign buyers because they come here to buy the garments products with a lot of money. So if they feel unsecured to come in this country we can’t sell our product in abroad and if fail to sell them we can not survive the market. For this reason the seller of our country should ensure any kinds of security they needs and also provide them other facilities what they needs. But in our country sometime the seller doesn’t careful about this site. If they find any lack in their security they can move to other country. So we have to alert in this particular area.

Lack of training programs:

The service providers do not have any relevant training and education in this particular sector. They are generally with 10-12 years of general education and learn designing while in job. But in this area train persons are very much needed who have a lot of knowledge in this area. But it is a matter of sorrow that in our country there is a lack of those types of institutions where they can train themselves as a skill and knowledgeable persons. But if we look in the others countries in the world we can see that they have a lot of institutions where they can train the persons who are interested in this sector. For this reasons they doing better in this sector.

Lack of creativity:

We already discuss that there is a lack of institutions in our country who can train the employees to grow their creativity in this sector. Creativity is so important because in every time the competitor tries to introduce new designs products in the market to use their creativity. So if we fail to show our creativity in our designs we can’t touch the market. There is little creativity as the customer normally comes with his/her own idea about the design but this is not enough for the RMG sector.

Maintain the quality of product:

Maintain the quality is very important in this sector. We already know that the international market is very much competitive and in this market if any body wants to survive he might have to maintain the good quality. If anybody fails to maintain the quality as much as high it is very tuff for them to stay in the market. If any company fails to prove its continuous quality it if sure that it might through from the market because any buyer can’t believe the company and as a result they cannot take any order from them. Sometimes our RMG sectors fail to maintain the quality and it is not a good symptom for our Garments Export.

Political Instability:

Bangladesh is not a stable country politically. Political instability is a great threat for any industry of our country. Frequent strikes and hartals are great obstacles for the growth of any industry. The production cost increases and productivity decreases because of frequent hartals and strikes. Garment producers cannot keep their contract with buyers because of hartals and strikes. Hartals and strikes have become a common phenomenon of Bangladesh.

Secondary Problems are –

01.Middle man affect

02. Sluggish Export linkage

03. Unloading(RM) takes time

04. Time consuming schedule

05. Communication gap

06. Dependency on foreign market

07. Trade block

08. Credit problem

Real threat of the foreign markets:

There is the real threat of the foreign markets entering in full swing with their capital as well as commodities and render millions of our people jobless. At the same time, it would throw unlimited opportunities for our better-organized Export houses. In other words, for those who are able to withstand the demands of open competition already. The quota regime will end and countries can freely import or export with reduced custom duties. The poor and the weak will certainly face the music. Governments have given their nod to GATT agreements, without sufficient analysis of the implications, mainly because it was a law for the future. And our politicians, who always fight for the present, can conveniently give away anything of the future. All the more if it is an issue of the weaker section.

There is yet another sentiment, which leads the country into the trap of the affluent. It is the inner deception and the bold announcements that we too are rich and advanced. “Second to none in the world.” While the judgment is often made based on the premier institutions of the Government, and the star trading houses of the upper society, the challenges of the lower middle classes are easily forgotten. Even the new textile policy threatens to go along the line of deregulation and deservation. If the Government is able to provide every handloom weaver with a power-loom unit with necessary training and infra-structure, well and good. We do not deny that the power looms have an economic edge over the traditional ones.

But the real question is, “Are our people prepared to take on the new technology?” That they can’t compete with the traditional loom is amply clear. Nor have they made sufficient fortunes to move to the next level on their own. In this context deregulation without adequate support to switch over the technology will only ruin the lives of 20 lakes weavers in the country. The technology up gradation fund could be used only if the entire machinery is modernized and if machines with above 16000 revolutions per minute (rpm) are installed in the place of the old.

The small spinners have come up vehemently against such tough conditions. They have argued that all the textile units are not meant for the export materials and that a vast population of India still needs clothes of ordinary material and not a highly mechanized and costly fiber. They demand for reasonable modernization within their existing units and the TUF funds should not close the door for them, in the madness after globalization and instant modernization.

Competitiveness of the Bangladesh RMG Industry

The United States was the main export destination for Bangladeshi RMG products in the early 1990s followed by the European Union, but the European Union has surpassed the United States over time. These two destinations generate more than 90 per cent of the total RMG export earnings of Bangladesh. The shares of other importers, such as Australia, Canada, China, Japan and the Russian Federation as well as countries in the Middle East, in the total RMG export earnings of Bangladesh are minimal. This section of the paper focuses on surface-level competitive performance of the Bangladesh RMG industry in the United States and the European Union markets only. In addition, the performance of China and India along with Bangladesh as RMG suppliers to international markets is also considered for comparative analysis.

(a) Export competitiveness in the United States market

Bangladesh has experienced some product diversification in its export of garments to the United States market in recent years compared with the early 1990s. However, the country’s performance in upgrading its products is not significant with regard to the United States market. The country experienced a sharp increase in the export of garment products to the United States market in the 1990s, but faced declines in export earnings from that country in 2002 and 2003, followed by slow increases since 2004. The exports of India also increased rapidly in the 1990s, although that country experienced comparatively slow progress in the last few years. However, the RMG exports of China to the United States have increased at a startling rate over the years. For example, the textile and garment export earnings of China, India and Bangladesh from the United States were $3.6 billion, $0.8 billion and $0.4 billion respectively in 1990, and increased to $22.4 billion, $4.6 billion and $2.5 billion respectively in 2005. Such rapid expansion in the exports of China represents a major challenge to other exporters.

(b) Export competitiveness in the European Union market

Bangladesh has experienced both quantitative and qualitative changes in exporting garment products to the European Union market during the period 1996-2005. The textile and garment export earnings of Bangladesh from the European Union increased from 1.2 billion euros in 1996 to 3.7 billion euros in 2005. For India and China, the corresponding earnings increased from 3 billion and 5.3 billion euros in 1996 to 5.3 billion and 21.1 billion euros in 2005 respectively. Garment products generate the major share of Bangladesh’s export earnings from the European Union. However, both textile and garment products in China and India contribute to the export earnings from the European Union. For example, garment products on average generated more than a 95 per cent share of the total textile and garment exports to the European Union from Bangladesh during the period 1996-2005. The corresponding shares for India and China stand at below 75 per cent and 80-90 per cent respectively.The top five product groups contributed 76 per cent of the total garment export earnings of Bangladesh from the European Union in 1996, and that share increased to 82 per cent in 2005. The corresponding changes for India and China were from shares of 62 per cent and 34 per cent in 1996 to 54 per cent and 45 per cent in 2005 respectively. This trend demonstrates that product diversification in Bangladesh is lower than that of India and China in exporting garments products to the European Union market. Knit garments from Bangladesh have gained remarkable access to the European Union market during the period 1996-2005

Duty- and quota-free access of garment products manufactured under “two-stage local transformation” (yarn to fabrics and fabrics to garment) have accelerated the exports of knit garment products from Bangladesh to the European Union. As the knit textile subsector is relatively less capital intensive and requires relatively simple technologies, it managed to undergo rapid expansion, benefiting from the European Union Generalized System of Preferences. The woven part of the category has failed to utilize that facility owing to a lack of sufficient backward linkages. In contrast to the European Union, both knit and non-knit products have entered the United States market simultaneously.

Unethical Perspective of garment Export in Bangladesh:

- High thermal problem that cause for many sick

- High dust cause for launch cancer

- Low pay for large work

- Child labor break the humanity

- Overrule the ILO concept about the worker.

- Bound environment causes for mental sickness to the worker.

- Problem relating to quality control for produce quality-full product & unethical movement of the organization.

- Most of the production cases Bangladeshis industry failure in making alternative inventory plan for wrong perception.

- Lack of accurate and appropriate goods of inventory because of unethical movement.

- Lack of low experience about production and manufacturing system because of there is no training for it.

Challenge of Globalization

Bangladesh faces the challenge of achieving accelerated economic growth and alleviating the massive poverty that afflicts nearly two-fifths of its 135 million people. To meet this challenge, market-oriented liberalizing policy reforms were initiated in the mid-1980s and were pursued much more vigorously in the 1990s. These reforms were particularly aimed at moving towards an open economic regime and integrating with the global economy.

During the 1990s, notable progress was made in economic performance. Along with maintaining economic stabilization with a significantly reduced and declining dependence on foreign aid, the economy appeared to begin a transition from stabilization to growth. The average annual growth in per capita income had steadily accelerated from about 1.6 per cent per annum in the first half of the 1980s to 3.6 percent by the latter half of the 1990s. This improved performance owed itself both to a slowdown in population growth and a sustained increase in the rate of GDP growth, which averaged 5.2 percent annually during the second half of the 1990s. During this time, progress in the human development indicators was even more impressive. Bangladesh was in fact among the top performing countries in the 1990s, when measured by its improvement in the Human Development Index (HDI) as estimated by the United Nations Development Project (UNDP). In terms of the increase in the value of HDI between 1990 and 2001, Bangladesh is surpassed only by China and Cape Verde.

While most low-income countries depend largely on the export of primary commodities, Bangladesh has made the transition from being primarily a jute-exporting country to a garment-exporting one. This transition has been dictated by the country’s resource endowment, characterized by extreme land scarcity and a very high population density, making economic growth dependent on the export of labor-intensive manufactures.

In the wake of the 2001 global recession, Bangladesh’s reliance on foreign countries as a market for exports and as a source of remittances has become obvious. If Bangladesh is to become less vulnerable to the economic fortunes of others, it will need to strengthen its domestic economy, creating jobs and markets at home. A strong domestic sector and an improved overall investment environment will provide a more stable source of income – like what the garment industry has provided so far – and will rekindle and sustain Bangladesh’s economic growth.

Prospects of the RMG Industry

Despite many difficulties faced by the RMG industry over the past years, it continued to show its robust performance and competitive strength. The resilience and bold trend in this MFA phase-out period partly reflects the imposition of ‘safeguard quotas’ by US and similar restrictions by EU administration on China up to 2008, which has been the largest supplier of textiles and apparel to USA. Other factors like price competitiveness, enhanced GSP facility, market and product diversification, cheap labor, increased backward integration, high level of investment, and government support are among the key factors that helped the country to continue the momentum in export earnings in the apparel sector. Some of these elements are reviewed below.

Market Diversification

Bangladeshi RMG products are mainly destined to the US and EU. Back in 1996-97, Bangladesh was the 7th and 5th largest apparel exporter to the USA and European Union respectively. The industry was successful in exploring the opportunities in markets away from EU and US. In FY07, a successful turnaround was observed in exports to third countries, which having a negative growth in FY06 rose three-fold in FY07, which helped to record 23.1 percent overall export growth in the RMG sector. It is anticipated that the trend of market diversification will continue and this will help to maintain the growth momentum of export earnings. At the same time a recent WTO review points out that Bangladesh has not been able to exploit fully the duty free access to EU that it enjoys. While this is pointed out to be due to stringent rules of origin (ROO) criteria, the relative stagnation in exports to EU requires further analysis.

Product Diversification

The growth pattern of RMG exports can be categorized into two distinct phases. During the initial phase it was the woven category, which contributed the most. Second phase is the emergence of knitwear products that powered the recent double digit (year-on-year) growth starting in FY04. In the globalized economy and ever-changing fashion world, product diversification is the key to continuous Export success. Starting with a few items, the entrepreneurs of the RMG sector have also been able to diversify the product base ranging from ordinary shirts, T-shirts, trousers, shorts, pajamas, ladies and children’s wear to sophisticated high value items like quality suits, branded jeans, jackets, sweaters, embroidered wear etc. It is clear that value addition accrues mostly in the designer items, and the sooner local entrepreneurs can catch on to this trend the brighter be the RMG future.

Backward Integration

RMG industry in Bangladesh has already proved itself to be a resilient industry and can be a catalyst for further industrialization in the country. However, this vital industry still depends heavily on imported fabrics. After the liberalization of the quota regime some of the major textile suppliers Thailand, India, China, Hong Kong, Indonesia and Taiwan increased their own RMG exports.

If Bangladesh wants to enjoy increased market access created by the global open market economy it has no alternative but to produce textile items competitively at home through the establishment of backward linkage with the RMG industry. To some extent the industry has foreseen the need and has embarked on its own capacity building.

Flow of Investment

It is plausible that domestic entrepreneurs alone may not be able to develop the textile industry by establishing modern mills with adequate capacity to meet the growing RMG demand. It is important to have significant flow of investment both in terms of finance and technology. Figure 3 indicates that the investment outlook in this sector is encouraging, although the uncertainties before the MFA phase-out period caused a sluggish investment scenario. In part the momentum in the post-MFA phase-out period is indicative of the efforts underway towards capacity building through backward integration. This is evident in the pace of lending to the RMG sector and in the rising import share of RMG related machinery. However further progress would be necessary to improve and sustain competitiveness on a global scale.

Policy Regime of Government

Government of Bangladesh has played an active role in designing policy support to the RMG sector that includes back-to-back L/C, bonded warehouse, cash incentives, export credit guarantee scheme, tax holiday and related facilities. At present government operates a cash compensation scheme through which domestic suppliers to export-oriented RMG units receive a cash payment equivalent to 5 percent of the net FOB value of exported garments. At the same time, income tax rate for textile manufacturers were reduced to 15 percent from its earlier level for the period up to June 30, 2008. The reduced tax rates and other facilities are likely to have a positive impact on the RMG sector.

Infrastructural Impediments

The existence of sound infrastructural facilities is a prerequisite for economic development. In Bangladesh, continuing growth of the RMG sector is dependent on the development of a strong backward linkage in order to reduce the lead time. However, other factors constraining competitiveness of Bangladesh’s RMG exports included the absence of adequate physical infrastructure and utilities.

Labor Productivity

The productive efficiency of labor is more important determinant for gaining comparative advantage than the physical abundance of labor. In Bangladesh, the garment workers are mostly women with little education and training. The employment of an uneven number of unskilled labors by the garment factories results in low productivity and comparatively more expensive apparels. Bangladesh labor productivity is known to be lower when it compared with of Sri Lanka, South Korea and Hong Kong. Bangladesh must look for ways to improve the productivity of its labor force if it wants to compete regionally if not globally. Because of cheap labor if our country makes the labor productivity in the apex position, then we think the future of this sector is highly optimistic.

Research and Training

The country has no dedicated research institute related to the apparel sector. RMG is highly fashion oriented and constant market research is necessary to become successful in the Export. BGMEA has already established an institute which offers bachelor’s degree in fashion designing and BKMEA is planning on setting up a research and training institute. These and related initiatives need encouragement possibly intermediated by donor-assisted technology and knowledge transfer. A facilitating public sector role can be very relevant here.

Supportive Government Policy

In contrast to the public sector-led import-substituting industrialization strategy pursued during the first few years after independence, the industrialization philosophy of the government changed rather dramatically from the late 1970s when the emphasis was on export-oriented growth to be spearheaded by the private sector. Towards this end, various policy reforms were implemented in the 1980s and 1990s. Some of these reformed policies contributed considerably to the growth of the RMG industry in Bangladesh.

During the 1980s, a number of incentives were introduced to encourage export activities. Some of them were new like the Bonded Warehouse Facility (BWF), while others like the Export Performance License (XPL) Scheme 37 were already in operation and were improved upon. Also, rebates were given on import duties and indirect taxes, there were tax reductions on export income, and export financing was arranged. Under the XPL scheme, exporters of non-traditional products received import licenses for specific products over and above their normal percentage allotment based on the f.o.b. value of their exports.

Under the Duty Drawback System, exporters of manufactured goods were entitled to get refund of duties and taxes paid on imported inputs used in export production, and also all excise duties paid on exported finished goods. For certain fast-moving items such as RMG, a notional system of duty payments was adopted in 1982-83. Under this system, exporters were exempted from paying duties and taxes on imports used in export production at the time of importation, but were required to keep records of raw and 21packaging materials imported. The duties and taxes payable on the imports were kept in a suspense account. Liabilities to pay the amounts in suspense were removed on proof of exports.

The discussion in this section clearly points to the positive contribution made by policy reforms to the growth of the RMG industry in Bangladesh. In particular, two policies– the SBW facility and the back-to-back L/C system- led to significant reduction in cost of producing garments and enhanced competitiveness of Bangladesh’s garments exports. It also allowed garment manufacturers to earn more profit which, when necessary, could be used to overcome difficulties arising from weak governance. Furthermore, poor governance, reflected in the leakage of duty-free imported fabrics in the domestic market, paradoxically enough also helped the garment manufacturers to earn extra ‘profit’ and thereby enabled them to absorb the ‘high cost of doing Exportes – a fall out of bad governance.

Suggestion

In order to sustain the smooth growth and development of the garment industry of Bangladesh, Government should play a key role to offer a good export policy. Otherwise the production, employment, earning of foreign currency and economic development of the country will be affected seriously. Some recommendations have been offered to face the problems of the garment industry of Bangladesh. Regarding the problem of RMG sector I’ve identified some recommendation for the betterment of this sector. The recommendations are as follows:

- The Government of Bangladesh should play a key role for the expansion of the market of garment by diversified items for manufacture and export. It is very important fact that there are many items in the RMG product lines which Bangladeshi entrepreneurs have not yet started production. Leather items, life jackets, gloves, bags etc. are among few such items. Among other items are umbrella, nylon school bags and jackets, ice sport kits and wears, staffed toys, high competitive market fashion garments are examples. There are numerous such items not yet touched by our entrepreneurs.

- Government also have some responsibility to improve the situation by providing- proper policy to protect the garments industries, solve the license problem, quickly loading facility in the port, providing proper environment for the work, keep the industry free from all kind of political problem and the biasness. Credit must be provided when the industry fall in need.

- All out efforts would be made and steps taken for production and export of high priced readymade garments in the light of the prevailing market demand. Immediate steps shall be taken to establish a Fashion Institute pending establishment of the Fashion Institute measures will be taken, under special arrangements, to extend expert services to match the actual demand. Liberal credit may be considered for capacity building and hiring technology for producer of high quality garments.

- Make sure that they can deliver the products by the due date. Because it increases the goodwill of the companies. If for any reasons the garments companies fail to delivery the products on the date it might hamper its goodwill and if the goodwill of a companies are hamper it is not possible for them to survive in the international market. Because when they fail to delivery the goods on the date the buyer might faces some loss because they already schedule their work with other companies and for this reasons the buyer might face some losses. They have to pay demurrage for this unusual situation. So in next time they obviously try to avoid this situation and as a result the failure company cannot take any order form them.

- We know that because of the increasing of the price of raw materials the cost of production of the garments products are also increases. So if the production cost increases the price of the finish goods also increase and because of that we can’t offer the buyer at a lower price in any garments products and for this reason there is a chance for our RMG companies to loose their position in the international market and in this situation any body can take the chance to hold their place. In this case the RMG companies can produce the raw materials in domestically. We know that the main raw material of this sector is cotton. So if it can produce domestically the cost of production can be minimizing.

- It is a big problem for our country that there is small number of qualified product designers available in RMG sector but it is so important for our RMG Export. Because we know there is a lot of competition in the international market and in their every country want to introduce new products with new design. We know that today’s world is very much style sensitive and the style changes very rapidly. For this reason to solve this problem our government can start some training center where the employee can improve their skill and also the RMG companies can establish that kinds of center personally or they can send some persons outside of the country because of training.

- To ensure any kinds of the security of the foreign buyers the RMG companies have to take any necessary steps which the buyer say them. For this purpose they can rent a house of a hotel which is safety for them and ensure all the basic facilities. Sometimes they can rent some vehicles for their easy transportation. They can provide them delicious foods what they like to eat.

- Our Garments Industries can improve their position in the world map by reducing the overall problems. Such as management labor conflict, proper management policy, efficiency of the manager, maintainable time schedule for the product, proper strategic plan etc.

To be an upper position holder in the world Garments Sector there is no way except follow the above recommendations. We hope by maintaining proper management and policy strategies our country will take the apex position in future.

Suggestions Regarding Fire Safety

We need to remember that when there is a fire, the first thing one should do is to run away from it. And this is what everyone does in such a situation. But the situation become dangerous and tragic when the escape doorways and gates are found locked. Precautionary should need to be adopted are given below:

1. Building should be constructed with fire resisting materials

2. Adequate exits and proper escape routes should be designed

3. Protection against fire and smoke should be ensured

4. Electrical wiring must be properly designed, installed and maintained

5. Escape routes should be lighted at all times, kept clear be indicated by signs

6. Regular fire drills should be held

7. Doors should be protected and should open along the direction of escape

8. Doors should not open on the steps and sufficient space should be provided.

9. Smoke/Fire alarm systems must be installed

10. Adequate number of extinguishers should be provided

11. Prior relationship with local Fire services should be established

Conclusion

The Ready-Made Garments (RMG) industry occupies a unique position in the Bangladesh economy. It is the largest exporting industry in Bangladesh, which experienced phenomenal growth during the last 25 years. By taking advantage of an insulated market under the provision of Multi Fibre Agreement (MFA) of GATT, it attained a high profile in terms of foreign exchange earnings, exports, industrialization and contribution to GDP within a short span of time. The industry plays a key role in employment generation and in the provision of income to the poor. To remain competitive in the post-MFA phase, Bangladesh needs to remove all the structural impediments in the transportation facilities, telecommunication network, and power supply, management of seaport, utility services and in the law and order situation. The government and the RMG sector would have to jointly work together to maintain competitiveness in the global RMG market. Given the remarkable entrepreneurial initiatives and the dedication of its workforce, Bangladesh can look forward to advancing its share of the global RMG market.