1.1 INTRODUCTION:

MBA (Regular), department of Business Administration in the final examination introduced internship program under the supervision of respectable teachers. For in this research my selected organization is “Shaya Apparels Ltd”. Located at, Savar Dhaka, & for the selected research subject is merchandising system of Shaya Apparels Ltd. So I am paying special attention on merchandising system of the company. In Bangladesh, the future of garments industries is brighter in the era of globalization. Ultra modern technology are being used in the woven and knit garment industries in the out side world other than Bangladesh .To survive in the free market of the world, we have to use world standard latest technology in our ready made garment sector. The report will mainly focus on the merchandising system of Shaya Apparels Ltd, Dhaka. The study will cover the practice, procedures and technique followed by the merchandiser in the preparation of order to shipment in Shaya Apparels Ltd. Bangladesh is a developing country. The development and progress of the country largely depend on export performance. In case of Bangladesh, among the export sector, the ready-made garments are the main earning source of foreign currency. In the garment and textile industry, merchandisers have been playing a vital role for the execution of export orders. There are large numbers of merchandising personnel who are working in the garment and textile sector.

At last, the main goal of the research was to analyze the following subjects:

- The system of merchandising of Shaya Apparels Ltd

- Inefficiency or weakness of merchandising (if any).

- The present merchandising system of Bangladesh.

- Development of merchandising in Bangladesh.

- Skills and necessary recommendation for achieving organizational goal.

1.2 BACKGROUND OF THE STDUY:

In the without the practical knowledge, theoretical knowledge is valueless. From this reason department of Business administration of SoutheastUniversity, Banani, Dhaka, has introduced an internship program with a view to achieve practical knowledge associate with the different fields of business. So after academic education this internship program was great opportunity for me to see the real business world, acquire practical knowledge and to be a smarter world business professional. For this reason to do my internship in Shaya Apparels Ltd a garment industry I communicate with a forwarding letter that was issued by the Department of department of Business administration of Southeast University, Banani, Dhaka, with my curriculum vita. I am very much grateful to the authority of Bengal Leisure Wear Limited for giving me the opportunity of doing my internship in this organization

1.3 STATEMENT OF THE STUDY:

The study will disclose present scenario of merchandising system and Practices at Bengal Leisure Wear Ltd. The topic “Merchandising system of Shaya Apparels Ltd.” gave me an opportunity to have an exposure to the working environment and on the job experience in merchandising of Shaya Apparels Ltd. In Bangladesh we specially means by “Merchandising” the merchandising of garments. A merchandiser is the most important person in a garment. All works in garments factory under the direction of a merchandiser. So merchandising is a challenging profession in a garments factory or area. If a merchandiser cans shipment the product properly, the buyer will be pleased on him and will get more order from them. So development of the merchandising profession will develop the textile area of Bangladesh. So, I selected this study.

1.4 OBJECTIVES OF THE STUDY:

The main objectives of this study are scrutinize the merchandising system of Shaya Apparels Ltd Academic knowledge is not perfect, practical knowledge is essential with it. The objectives of the study are to gather knowledge through practical work. It will fulfill the experience through theoretical as well as practically. So it is essential to rapid development of merchandising of a company especially in garment Company. Garments industry is the most important area of earning foreign currency. The followings are the main objectives of the present study:

- To define and evaluate the merchandising system of Shaya Apparels Ltd.

- To observe the effectiveness of merchandising department.

- To find out some problems and limitations of merchandising of Shaya Apparels Ltd

- To compare practical merchandising system and with theoretical approach (Marketing).

- To suggest some possible measures to over come the problems.

1.5 SCOPE OF THE STUDY:

There are so many garments industries in Bangladesh. Shaya Apparels Ltd is one of them. It is a small garments industry compare than others. There are only three merchandiser works. There are above 450labors and 40 staff works here. Though the organization is not so big and all related department situated in one building so that I can easily identify the person who had hold the relevant information needed to my study and collect data from merchandisers and other staff

1.6 REVIEW OF RELATED LITERATURE:

I am the first person who has done internship on merchandising system of shaya apparels Ltd. But some other persons who have done internship on merchandising system of other company that are given below:

SheikhMd. Rasel (2009) in the study conducted on ELEGANT TEAM DEVELOPMENT LIMITED tried show that how this buying house conducted their present merchandising system and what steps have to take for the development of merchandising system of this company. Sheikh Rasel study covers only marketing merchandising. My study also covers production-merchandising system of the company.

1.7 RATIONALITY OF THE RESEARCH:

It appears that merchandising is the most important and essential part of garments industry. But unfortunately in Bangladesh, merchandising planning and controlling is reported to be unsound in case of private sector industrial undertaking. It indicates that merchandising planning and controlling is extremely poor in all garments sectors like Shaya Apparels Ltd. In Bangladesh which in has adversely affected quality of the individual units. So far our knowledge goes; there is no other study on the subject. The rationality of merchandising system is stated bellow:

1. To know properly about merchandising of Bengal Leisure wear ltd.

2. To improve product quality.

3. To reduce lead-time.

4. To develop or set-up Background linkage industry.

5. To improve productivity.

6. To develop infrastructure.

1.8 RESEARCH METHODOLOGY:

The objective of research is to portray accurately the characteristics of a particular individual, situation or a group. Research refers to the systematic method consisting of enunciating the problem, formulating a hypothesis, and collecting the facts or data, analyzing the facts and reaching certain conclusions either in the form of solutions towards the concerned problem or in certain generalizations for some theoretical formulation. Research is the process of gathering, recording and analyzing critical and relevant facts about any problem in any branch of human activity. It refers to a critical and searches into study and investigation of problem, a proposed course of action a hypothesis or a theory.

Research refers to a search for knowledge. In fact research is an art of scientific investigation. The research methodology comprises of all activity that carried on in connection with marketing management.

The purpose of research is to discover answer to question through the application of scientific procedures. The main aim of research is to fins out the truth which is hidden and which has not been discovered as yet.

In brief, the research process consists of five steps:

- Defining the problem and research objectives.

- Developing the research plan.

- Collecting the information.

- Analyzing the information.

- Presenting the findings.

The scientific method, methodologies, model building and cost benefit measures of value of information can create a good research.

a) Sources of Data:

Collection of facts (raw facts) is known as data. There are two types of data are available based on source. These are:

1. Primary Sources of Data.

2. Secondary Sources of Data.

1. PRIMARY DATA

The data collected for a purpose or when the researcher investigates a particular problem

at hand is known as primary data

Sources of primary data:

Primary data for this study collected through direct observation and personal interview with questionnaire.

2. SECONDARY DATA

When an investigator uses data, which have already been collected by others for another purpose, such data is called secondary data. This type of data is primary data for the agency that collected them for the first time, and become secondary data for someone else who uses these data for his own purpose.

Sources of Secondary Data:

The major data have been used in this study are basically are of primary data. Secondary data for this study was collected from the organization and several reports.

b) Data Collection Instrument:

Direct observation and personal interview with questionnaire is the main instrument to collect the data. Both primary and secondary data have been used for the purpose of the study. The primary data have been collected on the basis of prepared questionnaire. Some secondary data and information have also been collected from the organization and several reports.

1.9 LIMITATIONS OF THE RESEARCH:

Actually, I have not faced any kind of mentionable problem in my research at Shaya Apparelsl Ltd. Several levels of officers, employees helped me in several conditions.

Though, I have faced a few problems, which I should mention to depend on the research.

The followings are some problems:

- The officers of several departments failed to give me enough time for their business.

- The merchandisers of they are always busy, so they could not sufficient records, facts and figures are not available.

- Usually Company is not willing to provide their actual data of financial statement because of their security such as they did not provide costing sheet to me.

- Personal barriers like inability to understand some official terms; office decorum etc. creates a few problems to me.

- The activities of a merchandiser are not documentarily arranged in this organization.

- The activities of merchandiser bear from factory to factory.

- It is not possible to learn about merchandising within 60 days.

- Lack of available of reburied data.

- There is no dyeing and printing and embroidering section in this organization. For this reason I did not have enough data about these topics.

2.1 INTRODUCTION OF SHAYA APPARELSLTD:

The Shaya Apparels ltd is one of the qualities ready-made garments industry in Bangladesh located Savar, Dhaka. It came into being in 2007 at cost of Tk.20 million and launched production in early 2008.

Two partners, in 2007 and production started at 2008 incorporated Shaya Apparels ltd. in Bangladesh as a private limited company. By dint of the stewardship, sincere intention to win the hearts and minds of the populace, taking the right strategy with quality and price, four knitwear products achieved on upsurge in consumer demand within a short span of time. The company, as a result, expanded by adding Euro based most sophisticated machinery. The total cost of the project now stands at Tk.20 million. Shaya Apparels ltd. occupies a huge position in the textile world of Bangladesh and its heart and mind-pacifying fragrance has spread over the foreign territories as well. Now the project is fulfilling the long cherished desire of the people of our country by supplying international quality garments and textile products within the competitive range of price.

Their international standard production unit is equipped with modern quality control procedure and microbiological lab with latest technology and a group of top professionals. All of the Garments are marketed under the brand name of “Bengal Leisure Wear”. Each stage of production undergoes rigorous testing and quality control process. The finished products are again tested to ensure the desired standard of quality before placing products in the market. The raw materials and active ingredients of products of Four knitwear Ltd. are imported from reputed manufactures of ,Canada , Italy, France, Germany, Spain, Sweden, England and USA. Quality comes first keeping this principle in mind; it aims at producing guaranteed international quality garments for quality conscious people of home and abroad.

2 THE PROFILE OF SHAYA APPARELS LTD:

Head Office : Shaya apparels ltd,

Hatem ali complex, Hemayetpur ,singair Road

,savar ,Dhaka

Factory : Hatem ali complex, Hemayetpur ,singair Road

,savar ,Dhaka, Status : Private Limited Company By shares

Incorporation No :

Contact Number : Tel:+88-027741498

Web:www.shaya-apparels.com

Contact Person : AKhter Hossain Liton(Managing Director)

MD. Aminul Islam dola(Director Marketing & Finance)

Name of the Banker : Bangladesh Krishi Bank

Banani corporate Branch

Production Space : 18000squire feet in three floors.

Fabric suppliers :.Faiasl Spinning Mills ltd

Saiham Textile Mills ltd

Nrg Home tex Ltd Export Outlets : Germany, France, and Turkey. South Africa,

Canada.

Authorized Capital in Taka : 30,000,000.00

Paid-up Capital in Taka : 20,000,000.00

Number of partners : Five

Stock Exchange Listing : No

Power Supply : Industrial 440 volt electric supply from Govt.

source. In addition to that, standby generator with

full capacity of the factory (120 KVA) brand FG

Wilson, UK.

Number of workers : 450 Female and male skilled workers at different

Categories.

Production Capacity : Monthly production capacity is 3,00,000pieces of Fleece Jackets or 80,000pieces of polo shirt or

2.3 OBJECTIVES OF SHAYA APPARELS LTD:

To manufactures and sell high quality clothes products to the people of all age group within affordable price. “No compromise with Quality” is the key policy of the Top Management. They believe that, they are reasonable and accountable to all concerned with whom they deal; namely: their employees, their business associates, their consumers and their buyers

Product OF SHAYA APPARELS LIMITED:

- Basic T-shirt

- Polo Shirt

- Fleece Jacket,

- Pajama

- Tank Top

- Trouser w/Seam pocket

2.4 ORGAN GRAM OF THE COMPANY:

6 MACRO ENVIRONMENT SITUATION OF THE COMPANY:

To develop a well relevant and rational Merchandising strategy a merchandise manager has to analysis the macro environmental forces may be a major variable for marketing activity. Remaining the rapid changing global picture Shaya Apparels ltd. must monitor six major forces such as:

Demographic Economic

- Natural

- Technological

- Political/legal

- Cultural etc.

In the aspect o Shaya Apparels ltd f. the main macro environment forces are to be discussed as bellow.

2.6.1 Demographic Environment:

Demography is the study of human population in terms of soiree, density, location, age sex, race, occupation and other information. The demography environment is major interest to marketers because it involves people and people make up the markets.

2.6.2 Economic Environment:

The economic environment consists of factors that effect available buyer relation and World economic situation. Total buying situation depends on current economic position of the world and prices of product and credit policy. The economic environment o Shaya Apparels ltd f. is better than other. The Company is accepting the challenge posed by a changing world economy use of the opportunities.

2.6.3 Natural Environment:

The natural environment involves natural resources that are needed as input use by marketers of which are effected by marketing Shaya Apparels ltd. use of various types of chemical and raw materials which has natural impact.

2.6.4 Technological Environment:

Technology is the most significant factor in the Shaya Apparels ltd. Shaya Apparels ltd. is the most modern garments Company in the Asia pacific region. The garments company use of the most advanced and high tech equipment from world’s leading manufactures. Shaya Apparels ltd. has used very latest and computerized modern technology. Technological environment support other machine of this company are-

The company has a completely self sufficient infrastructure with the complete power steam refrigeration, compressed air and water requirements for operation generated in house

- Chemical and water waste is cleaned in a modern effluent treatment plant complying with the most stringent international standards.

2.6.5 Political and legal Environment:

Merchandising division is strongly affected by the development of political and legal environment. The environment is composed of laws, government’s agencies and pressure groups that influence and limit various organizational and individuals.

2.6.6 Cultural Environment:

Cultural environment is made up of institutions and other forces that affected society’s basic value, perceptions, preference and behavior.

Cultural factors are important for Shaya Apparels ltd. products because the cultural factors affect on garments goods.

2.7 VARIOUSDEPARTMENTS OF SHAYA APPARELS LTD:

1. Merchandising Department:

This department is very much important for every garment industries. Merchandiser is a data bus between buyer and seller. Merchandising department perform the activities from collecting order to reaches the product on buyer. This department is responsible for providing all the raw materials needed for all kinds of garments products.

2. Accounts Department:

All the accounts of the organization are controlled by the accounts and administration department. Accountant record all the accounts, calculate profits or losses, prepared financial report

3. Commercial Department:

Total transportation activities, i.e. Import-export, L/C open, or any other banking activities performed by commercial department. Commercials manager cover all the activities.

5. Human Resource Department:

This department is very much important managing staff and employee of the company. It looks after the problem and opportunities of the company’s employee.

5. Production Department:

Under production department there are various sections that are given below:

A. Knitting and dyeing section:

It’s a process of fabric manufacture by converting yarn into loop form and than these enter lock/intermesh/inerloop together, which from a structure is called knitting structure/knitting fabric

Classifications of knitted structure are given below:

- Weft knitted structure

A. Circular knitting

a. Small dia m/c

b. Large dia: 1. Fabric for clothing

2. Single jersey

3. Rib category

4. Double jersey

5. La-coste

B. Flatbed knitting

a. Hand Driven: 1. Driven manually

2. Can product limit design?

3. Low volume production

4. Integrated garment not possible

b. Power Driven: 1. Driven by power

2. Can produce

3. Unlimited

4. High volume Production

5. Integrated Garment possible

- Warp Knitted

A. Tricot

B. Rachel: 1. Mesh fabric

2. Mosquito

3. Laces

4. Power net

B. Cutting section:

QUALITY CONTROL DEPARTMENT:

This department always cares on quality. This dept. control by the Q.C. Managers. They verify the quality as the buyer indicates their order. They audit all the process, pre-production to packing & final audit. Q.C.process is indicated previous.

C. Sewing section:

Tools & equipment of sewing section are given below:

1. Rack for cut fabric keeping (for every line)

2. Desk for trims keeping (with lock for every line)

3. Issue register (one for every line)

4. Attendance Register (one for every line)

5. Drawing / Marking table (Three for every line)

6. Supporting table for bigger components operation (as per required)

7. Desk (one for every operator)

8. Basket (five to six for each line)

9. Shoe bag (one for each operator & helper)

10. Toilet Card (one for every line)

11. First Aid Box (for every floor)

12. Fire extinguisher (at every corner of the factory)

13. Hammer

14. Z punch plunk

15. Big scissors

16. Small Scissors / clipper (for every operator & helper)

17. Are puncher / gimlet

18. Hand needles

19. Bodkin

20. Manila board /paper board

21. Tailor chalk

22. Pencil

D. Wash room

E. Iron section

F. Finishing section

G. Store section

2.8 SCHEDULE OF FIXED ASSETS OF Shaya Apparels ltd. (AS ON 30.6.2010):

| Particulars | Cost ( Taka) |

| 1. Land | 4,447,000 |

| 2. Plant & machinery | 6,324,715+3,569,777 (new) |

| 3. Renovation of Factory | 35,037.00 |

| 4.Fire Extinguisher | 132,858.00 |

| 5. Installation and Erecting | 1,176,353.00 |

| 6. OfficeBuilding | 1,217,772.00 |

| 7. Office Equipment | 830,907.00 |

| 8. Furniture & Fixture | 1,447,720.00 |

| 9. Vehicles | 10,000 |

| Total | |

Source: Annual Report of Shaya Apparels ltd. (2011).

2.9 FACILITIES F OR STAFFS AND EMPLOYEES FROM SHAYA APPARELS LTD.

Shaya Apparels ltd. is one of the profitable companies in Bangladesh. In view of acute un-employment situation of the country Shaya Apparels ltd. give following benefits to all level of staffs and employees every year:

- Appoint young, energetic and fresh individual. Shaya Apparels ltd had taken bold decision to appoint young, energetic and fresh individual to solve un- employment problem from this poor country.

- Overtime facilities: In this organization the employees work 6 days in a week. Work starts from 8 am to 5 pm. The work is performed at one shift. For that there is a scope to work after 5 pm to 8 pm. In this over time period employees get double wage. It is a legal source for the employees to earn extra. There is also a break time for launch for one hour.

- Festival bonus: Every employee gets festival bonus in two Eid (salary or wage). Beside this they also get another bonus for extra production and part of profit.

- Mental refreshment: Every year all level of employee gets the benefit of yearly picnic and sports and cultural program.

- Training facilities: Shaya Apparels ltd. budgeted an amount for the skill development of their selected staffs and employees.

- Transportation facilities: Every staff of four knit wear limited get transport facilities in office work purpose

- Residential facilities: The organization has residential facilities for employees. They get house rent in time of salary. Though there prevails unhealthy atmospheres, but it is better than other ownership house.

- Medical facilities: There is a medical facility to all employee of the company. In this company doctor teams come to factory directly for medical support.

- First aid facilities: Shaya Apparels ltd has a primary medical for facing any kind of unfortunate accident, which cost a part of budget every year

- Research and development facilities: There are a budget for research and development of Shaya Apparels ltd. each year. So, any one can get an opportunity to research for his/her skill.

- Prayer facility: At the time of prayer the Muslim employee have the place for prayer but others have no facility.

2.10 MAJOR BUYERS OFSHAYA APPARELS LTD:

| Buyer Name | Country Origin |

| BERNARDI | ITALY |

| PUNTOCENTRAL SA | SPAIN |

| HELENS | SWEDEN |

| VAN DILLEN ASIATEX GMBH | GERMANY |

| TAPE A L OEIL / MIM | FRANCE |

| EURODIF | FRANCE |

| ZERO SPORTS | CANADA |

| UNIVERTEX | FRANCE |

2.11 MAJOR RAW MATERIALS OF SHAYA APPARELS LTD:

1. Fabric

2. Threat yarn

3. Level

4. Cartons

5. Folders

6. Strikers

7. Eye late

8. Button

9. Zipper

10.Sewing thered

2.12 LIST OF MACHINERY:

Brand new machines directly imported from manufacturers. The numbers of machine are 175 Pcs.

LIST OF MACHINERIES:

| |||||

COMPANY NAME | MACHINE NAME | MACHINE TYPE | ORIGIN | QNTY | |

SIRUBA | Over lock | 4 Thread | TAIWAN | 37 | sets |

PEGASUS | Over lock | 4 Thread | JAPAN | 9 | sets |

SIRUBA | Plain Machine | TAWAN | 28 | sets | |

SIRUBA | Plain Machine | Computerized | TAWAN | 2 | sets |

FDM | Plain Machine | Computerized | CHINA | 16 | sets |

BROTHER | Plain Machine | Computerized | JAPAN | 8 | sets |

SIRUBA | Flat lock | Slider Bed | TAWAN | 12 | sets |

SIRUBA | Flat lock | Flat Bed | TAWAN | 2 | sets |

SIRUBA | Flat lock | Piping Set & Flat Bed Set | TAWAN | 5 | sets |

PEGASUS | Flat lock | Slider Bed | JAPAN | 4 | sets |

PEGASUS | Flat lock | Piping Set | JAPAN | 3 | sets |

JUKI | Flat lock | Slider Bed | JAPAN | 1 | sets |

KANSAI | PMD- 4 Needle | 4 Needle | JAPAN | 1 | sets |

KANSAI | Smock Machine | 25 Needle+ 9 Cam | JAPAN | 1 | sets |

SIRUBA | Picketing Machine | Double | TAWAN | 1 | sets |

MAX | Zigzag Machine | CHINA | 1 | sets | |

SIRUBA | Back Tape Machine | 2 Needle Chain Stitch | TAWAN | 1 | sets |

BROTHER | Button Stitch Machine | Computerized | JAPAN | 1 | sets |

BROTHER | Hole Stitch Machine | Computerized | JAPAN | 1 | sets |

MAX | Eyelet Hole Machine | CHINA | 2 | sets | |

MAX | Rib Cutting Machine | CHINA | 1 | sets | |

MAX | Fusing Machine | Computerized | CHINA | 1 | Pc |

Label Cutting Machine | LOCAL | 1 | set | ||

JUKI | Smocking Machine | 25 needle | Japan | 1 | set |

OSIMA | Thread Sucking Machine | CHINA | 1 | set | |

K.M CUTTING | Cutting Machine | JAPAN | 2 | sets | |

AUTOWIN | Re-Coning Machine | CHINA | 1 | set | |

MAX | Iron Vacuum Table | CHINA | 10 | sets | |

STEAM IRON | Iron | CHINA | 12 | sets | |

MODERN | 100 KG GAS BOILER | BANGLADESH | 2 | sets | |

Exhaust Fan | BANGLADESH | 4 | sets | ||

Cutting Table | BANGLADESH | 2 | sets | ||

CUMMINS | GAS GENARATOR-120 KVA | ARGENTINA | 1 | Set | |

Chapter-Three

3.1 CONCEPT OF MERCHANDISING:

The term “merchandising” is well known to the person specially involved in garments trade. The term merchandising has been derived from the term “merchandise”. Merchandise means goods that are bought and sold. The term merchandiser may be defined as the person who merchandises the goods especially for export purposes. Garments merchandising means buying raw materials and accessories, producing required garments, maintaining required quality level and exporting the garments within schedule time frame.

3.2 MAJOR RESPONSIBILITIES OF A MERCHANDISER ARE GIVEN BELOW:

1. Order sourcing/supplies

2. Negotiation

3. Production

4. Calculating Yarn/Fabric consumption

5. Calculating costing of the product

6. Monitoring Quality aspect

7. Product development

8. Liaison with Buyers Customers & Factory

9. Factory Scheduling

3.3 QUALITY OF A MERCHANDISER:

From the above definitions we can assume that a person involved in garments merchandising needs a wide range of knowledge and skill.

a). Good command of English and adequate knowledge of technical terms for accurate and efficient communication.

b) Good knowledge of yarn , fabric , dyeing, printing, finishing , dyeing color fastness, garments production etc.

c) Clear conception of the usual potential quality problems in the garments

manufacturing.

d) Good knowledge of the usual raw materials inspection systems and garments inspection systems.

e) Knowledge of the quota system used in each of the producing countries , duty rate , custom regulation, shipping and banking documentation etc.

3.4 FUNCTION OF A MERCHANDISER :

When an export order is placed to a merchandiser, he has to schedule the following main function to execute the export order perfectly in time

1. Fabric requirement calculations.

2. Accessories requirements calculation

3. Sources of fabrics

4. Possible date of arrival of fabrics And accessories in the garments factory

5. Costing

6. Garments production planning

7. Pre shipment inspection schedule

8. Shipment document

All the main functions, mentioned above are important but the procurement of fabric and

accessories are most important as because there are many technical parameters involved,

specially in this area, in most cases collection of fabric for the garments is a major problem. To procure a fabric, we should clearly specify the technical specification of the

fabric during placing a fabric supply order.

3.5 WHAT BUYERS LIKE OR DISLIKE IN A MERCHANDISER?

** What buyers like in a merchandiser?

1. Good presentation: Calculator, Paper, and Scale etc.

2. Manner: Manner should be polite, good Behavior, Smart talking

3. Time Awareness: You should be punctual & sincere

4. Knowledge: About product, your company & about buyers

5. Sensibility To the needs: Lessening, understanding

6. Appearance: Smart Dress, Formal dress, and casual dress

** What buyers dislike?

1. Poor sales presentation

2. Unacceptable manner

3. Time wasting

4. Un-smart appearance

5. Poor knowledge

3.6 PURPOSE OF MERCHANDISING:

1. To collect order from the buyer.

2. To shipment the order in time.

3. To follow up the working of worker.

4. To determine the actual price of the product.

5. To improve the quality of the product.

6. To increase the goodwill of the textile.

7. To seek new buyers.

3.7 MERCHANDISING MANAGEMENT:

Merchandising management constitutes the most significant part of textile companies. A company starts their activities by starting the activities of a merchandiser. When a company receives an email from buyer, then the activities of a merchandiser start and a merchandiser always look after all activities from production to shipment.

1. Receive email of the buyer or buying house

2. Determine the actual price of the product

3. Send sample of the product

4. Ensure a good quality of product

5. Follow up the production process.

6. Monitoring the payment.

3.8 OBJECTIVES OF MERCHANDISING:

Efficient Management of merchandising should ultimately result in the maximization of sales of products. In order to minimize cost

Stated differently that the objectives of merchandising management consist of two counter-balancing parts: –

- To maintain merchandising system for efficient and smooth production and sales operations.

- To maintain a minimum cost to maximize profitability.

These two conflicting objectives of merchandising management can also be expressed in terms of cost and benefits associated with inventory. That the industry should minimize cost of product for increasing more sales and more profit.

Chapter-Four

THE MERCHANDISING ACTIVITIES OF SHAYA APPARELS LTD

4.1 FORECASTING:

It is an important term for merchandising. At first a merchandiser has to decide in what type product he will produce. There are various products in textile sector. After deciding the product then he will start for order sourcing.

4.2 SOURCING OF BUYERS & ORDERS:

One of the prime jobs of merchandisers is sourcing international buyers and orders from them. Sourcing buyers and orders is not an easy job. It requires skill, experience, acquaintance & intelligence. There are hundreds and thousands of buyers sourcing fashion products from throughout the globe. So sourcing takes place in two ways.

- Buyers sourcing fashion products for their clients and markets.

- On the other hand factories endeavor to source right buyers and right products for their organization.

This match making is not so easy and comfortable matter. A factory has must adequate working experience, good management system, safety and security system, workers welfare system and compliance to get orders from foreign buyers. So prior to providing orders, buyers check the vendor factory whether the concerned factory is right one to deliver them the goods they require. The general rules that are followed by Bengal Leisure Wear Ltd. are as given below:

- Compliance test

- Streamlining all sorts of management systems in the factory.

- Safety & security of the facilities and personnel.

- Working sub-contracts for the buyers.

These checks and test gradually move from company to buyers and merchandisers of the Bengal Leisure Wear Ltd. Submit catalogs, brochures, samples to the buyer due to grow the confidence of concerned buyer about quality of the factory. Once the buyer is satisfied with the different aspects of the factory, it may start providing orders to the factory.

In order to be successful in sourcing buyers, the following attributes are very important:

1.High quality product.

2.Shipment on time.

3.Short lead time.

4.Full buyer’s satisfaction.

5.Employee empowerment.

6.orporate social responsibility

7.All this attributes may lead to sourcing reputed buyers

8.A list of famous buyers operating in Bangladesh is given below_

LIST OF INTERNATIONAL BUYERS

| BUYERS | THEIR PRODUCTS |

| NIKE | Sports wear, jacket, wind breaker etc. |

| Adidas | Sports wear, athletic shoes, jacket etc. |

| JC Penny | Miscellaneous fashion products. |

| Reebok | Sports wear, sports shoes, active wear etc. |

| Lee, Levi’s Strauss | Jeans and sports wear. |

| Wrangler | Jeans and sports wear. |

| Bugle boy | Jeans and sports wear. |

| Guess | Jeans and sports wear. |

| Fruit of Loom | Underwear, daywear etc. |

| Playtex | Bra, shape wear etc. |

| London Fog | Outer wear, Rain wear etc. |

| Nordstorm | Men’s wear. |

| Stafford | Men’s wear. |

| Claiborne | Sport’s wear. |

| The Gap | Sport’s wear. |

| Christian Dior | Tailored clothing. |

| Hart Marx | Custom ordered clothing. |

| Arrow | Shirts, neck wear, sweater, underwear etc. |

| Pendleton | Shirts, neck wear, sweater, underwear etc. |

| Champion | Children’s wear. |

| Tommy Hilfiger | Children’s wear. |

| Walt Disney6 | Children’s wear. |

| Eber | Children’s wear. |

| Carter’s | Children’s wear. |

| Espirit | Children’s wear. |

| Osh Kosh B’ Ghosh | Children’s wear. |

| Wall Mart | Divergent garment product. |

| K Mart | Divergent garment product. |

| Cabela | Sportswear, etc. |

4.3 Negotiations to the Buyers:

One of the most important competencies of a merchandiser is his ability to successfully negotiate with a buyer or a supplier. With these skills he generally secures a successful order from a buyer at right price and other terms and conditions on one hand. On the other hand he is able to place order to a right supplier At a right cost and delivery schedule. The most important topics of negotiations are generally fixing the price of the product. But the other issues include order volume, lead time, delivery and payment terms.

4.3.1 Definition of negotiation:

The negotiation, also called bargaining, is a process of communication and trading of ideas between two parties by which they make a series of demands and compromises so as to come to a desired point of mutual acceptance so that both parties benefit from the transaction of business. It is a series of communication and discussion, which may go very hard but running in a friendly environment so as to come to a mutually beneficial position. The function of negotiation is not to push the other party to defeat rather to work out a win-win solution so that both parties can transect business with profit.

4.3.2 Why do we negotiate? :

We negotiate with a buyer or supplier for the following reasons

- We want to secure an order from the buyer or place an order to a supplier.

- We need to fix a cost/price of the product for mutual benefit.

- We require lowering the cost or increase price of the product.

- We need to fix production and shipment plan.

- We must determine payment terms and conditions mutually profitable or acceptable.

4.3.3 The negotiation process:

Of late, negotiation has become a science business open become successful or a failure due to the success or failure of the negotiation technique. So a buyer or merchandiser or supplier must be aware of the steps necessary for a successful negotiation.

We must adequately know the requirements of both the parties: A merchandiser must well understand the requirements of the buyer, his organization & supplier. The buyer has intended retail selling price in his mind. So merchandiser must have sufficient knowledge of garments construction & standard time of product. He may put forward suggestions so as to bridge up cost price and buyers target price, lead time, delivery schedules etc. are issues which a merchandiser can use for fruitful negotiation. The status negotiation often shows up in facial expressions, body languages and verbal reactions, which a merchandiser must well observe for successful outcome of discussion. Merchandisers must listen to and observe the negotiating parties so as to trade benefits own favor.

2. Merchandisers must adequately prepare for the negotiation: Merchandiser must properly prepare for meeting & trading the negotiation. There should be an agenda & time frame for the meeting. Merchandiser must be fully aware of garment item to be negotiated, product price, order quantity, leading time, freight, garments construction, fabric consumption, cutting, making, charges for printing, embroidery, standard time for the garment etc. so that he is fluent about all aspects of negotiation. Full preparations from the side of the merchandisers about al aspects help come to a successful outcome very quickly. Merchandiser as a negotiator must have maximum & minimum position in respect of the order, its price, delivery schedule, order volume etc.

3. Discuss the offer: During discussion merchandiser must identify the position of the buyer in respect of the offer and if necessary sets his boundary for farther negotiation. It is very mush expected that different aspects of the offer may change during the course of the negotiation.

4. Further discussion: at the stage each party weight proposals of the other party. Merchandiser must care fully observe the tone and wording of the buyer, his facial expression and body language interest or disinterest and where the final boundary of the buyer lies.

5. Final or revised offer: this is the final stage of negotiation when details of the offer are worked out. The details may include construction and specifications of the garment, order, size, order quantity, leading time, freight, garments construction, fabric consumption, cutting, making, charges for printing, embroidery, standard time, payment terms etc. the buyer makes final offer and the merchandiser as a negotiator must ensure that the offer is profitable for his company.

6. Making an agreement: Merchandise must make their best efforts so that negotiations culminate into real agreements financially beneficial to his company. As soon as negotiation succeeds the buyer communicates details to the manufacturing company represented by the merchandiser. This detail takes the form of a master L/C, P.O shit or work sheet.

4.4 RECIVING ORDERS FROM BUYER:

Companies normally receive order from buyer through worksheet. A worksheet is a document where every details of the specific garment product are included. As soon as the worksheet at hand the manufacturing company may go for booking order for fabrics, trims, accessories as well as making production and shipment plants.

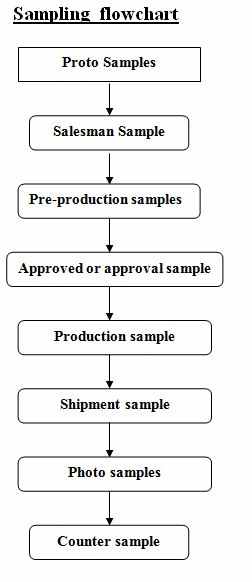

4.5 SAMPLING PROCEDURE:

4.5.1 Definition of Sample:

A few items or goods taken from a large number of similar goods are called samples of that large number of goods. If there is a stick of same types & origin of apples, we may call that stick as population or lot size.

In the garments trade the following samples find to be used:

1. Proto Samples: These are sample developed during the preliminary stages of product development. They are made by similar but not always exact fabrics & trims.

2. Salesman Sample: These are the samples used by the buyer for promotion or sales of their product. Salesman sample are generated from approved proto sample. Salesman samples may be produced from fabric & trims of only one style & color. Proto & salesman samples may or may not be produced by the vendor factory. Buyers get them generated by their own product development cell or by any of their vendor factory.

Pre-production samples: Preproduction samples are produced by the vendor factory as per instruction of the buyer. They are produced prior to the commencement of production.

Approved or approval sample: Upon approval of the pre production samples by the buyer, they will be sealed and tagged with comments if necessary. One set is kept under buyer’s disposal and two sets are sent to the vendor. The approved pre production samples are called approved samples. They are made by the vendor factory.

Production sample: Representative samples taken from a production line on random basis by buyer’s representative is called production sample. Production sample speak out the quality level of the product to the buyer.

6. Shipment sample: A shipment sample is sent to the buyer at the time of buyer at the time of shipment.

7. Photo samples: There is another category of samples called photo samples. This samples are photograph for making brochures, catalogs, etc. for distribution to stores and for end-users

.8. Counter sample: Some times we require approved samples in different departments but we have only one approved sample. We may reproduce a number of samples against the available the approved sample. A sample reproduced from a sample is called counter sample.

4.6 QUICK RESPONSE MATERIAL SOURCING:

4.6.1 Source Fabric:

After receiving the enquiry a merchandiser have to find from where fabric can be found as per buyers requirement. There are two sources of fabric.

1. Local source

2. Foreign source.

Both local and foreign it needs to open a L/C. In textile sector generally back-to- back L/C is used to collect Fabrics.

4.6.2 Prepare Lab Dip:

It is an important part of sampling. If buyer wants color size product then he need to send them to textile mills for proper coloring. Lotus Kamal knitwear ltd prepares lab-dip sample for Apparels Ltd due to supply that fabric.

After that lab test is send to the buyer for approve. For an example Letter that is send to lab is given below-

Date:

To

Mr. Babul

Knit Concern Ltd.

Sub: Lab Dip Programmed

Buyer Name: Info-united

Art:-Zob-3

Fabrics- 65%Cotton, 35%Polyester, S/J 180 GSM

| SL# | Color name | Pantone/Shade | Fabrics | Remarks |

| 01 | Orange | 158C |

4.6.3 Gets approval of Lab dip:

Lab Dip confirmation & may be fitting & workmanship changes:

1) Start with dyeing the fabric (if necessary start tests bulk)

2) Sending preproduction samples or size set in original fabric with all already Confirmed details.

4.6. 4 Trims & Accessories Sourcing:

For preparing a product a company needs various types of trims and accessories. These are very much important for garments product, Such as tag, pin, scope tape etc. so it is the duty of a merchandiser to sourcing accessories before start production.

4.7 PLACING ORDER TO SUPPLIER:

4.7.1 Ordering for fabrics and other materials:

In the fashion industry it is of utmost importance that material for the garments must be arranged on the floor of the factory in right quality, right quantity and right time so that

Production may commence on designated schedule. In Bangladeshi apparel industries arranging inputs in right time is probably the most serious challenge that most of the factories are unable to do. All other problems as such as disruption of production, failure of production, and shipment schedule, escalation of lead time emanate from the problem of failure in securing materials on time.

4.7.2 How to place for fabrics:

Order for materials is placed to supplier through a negotiated instrument or through a back to back L/C. This instrument must comprise comprehensive specification of fabrics and other materials. Besides, approved material samples, if possible, should also be supplied to the supplier for accuracy and right follow up. The instrument/contract should also include a clause on in-process and pre-shipment inspection of goods so that no faulty goods can be shipped.

Specification to be provided to the supplier regarding woven fabric:

- Sample approved by the buyer(if possible);

- Fabric construction,

- Fiber content and yarn count,

- Type of yarn (ring spun, open end, combed, carded etc.);

- Fabric width,

- Type of looms (shuttle loom, shuttle less looms) in which fabric should be produced;

- Type of dye to be used,

- Standard of color fastness,

- Piece length size: Piece length with no seam (such as 80% of rolls should be more than50 meters long with no seam),

- Fabric finish: type and level of fabric finish as specified by buyer;

- Packing: Type of fabric packing should be specific such as, rolled on tube and each roll in an untearable poly & poly bags to be packed in 3-ply cartons.

- Labeling & Marketing: sometimes suppliers are instructed to stamp or mark both ends of fabric with company stamp, yardage of the fabric rolls on outside paper labels. Beside they are instructed to affix a paper label to one end of fabric roll to show the following: style, color name or color code, roll and yardage, etc.

4.8 SWATCH MAKING & APPROVAL:

Swatch is a presentation of all the materials is (Fabric & Accessories) used for any specific style/order. Usually small piece of fabric and each piece of accessories are attached in board paper in a systematic manner. Swatch is very important for production line to make the correct construction of a garment and QC department ensures it. Swatch is also being called trim card.

4.9 CONSUMPTION

4.9.1 Fabric Consumption:

The quality of fabric required to produce a garment is known as fabric consumption. In the garments industries, fabric consumption often refers to fabric requirement per dozen of garments rather than a unit garment. Knowledge of fabric consumption is very important at the time of securing order from the buyer otherwise quoting price for the order will be an impossible task.

Fabric consumption of Knitted T-Shirts:

Sketch of a T-shirt with some measurement is given below:

Size Specification for Knitted T-Shirt:

| Code | Measuring Position | S | M | L | XL |

A | ½ Cheat | 48 | 52 | 56 | 60 |

B | ½ Bottom | 46 | 50 | 54 | 58 |

C | Front Length From Shoulder | 66 | 68 | 70 | 72 |

D | Shoulder to Shoulder | 39 | 42 | 45 | 48 |

E | Shoulder Slant to be Graded | 4.5 | |||

F | Sleeve Length | 22 | 23 | 24 | 25 |

G | ½ Armhole | 21 | 22 | 23 | 24 |

H | ½ Biceps | 18 | 19 | 20 | 21 |

I | Sleeve Head to the Graded | 13.5 | |||

J | ½ Bottom Sleeve | 15.5 | 16.5 | 17.5 | 18.5 |

K | Neck Width | 16 | 17 | 18 | 19 |

L | Neck Drop CF | 9.5 | 10 | 10.5 | 11 |

M | Neck Drop CB | 2 | 2 | 2 | 2 |

N | ½ Minimum Extended Neckline | 30 | 30 | 30 | 30 |

Example:

A T-shirt has a body length of 80 cm & body width of 55 cm. It has sleeve length of 25 cm. Fabric GSM is 180. Then calculation of Fabric consumption :

Area of garment = Body Area + Sleeve Area

= (Body length + Sleeve length) Í Body width Í2

= (80 + 25) Í55 Í2

= 11,550 sq. cm + wastage 18%

= 13,629 sq. cm

= 1.3629 sq. m

Weight of fabric = 1.3629 Í180 ÷ 1000 = 0.2453 kg per piece × 12 = 2.94 kg per dozen.

Thus fabric consumption per dozen = 2.94 kgs.

Note: 180 GSM means that 1 sq. m fabric weights 180 gm.

4.9.2 THREAD CONSUMPTION FOR PRODUCTION OF GARMENTS:

Garments production requires different types of stitches and seams. They influence thread consumption to a large extend. A table is shown below giving thread consumption per centimeter of seam for different stitch types.

List of thread consumption under different stitch type

| Sl | Stitch type | code | Thread consumptionPer cm of seam | # of Needles | Needle,Thread & Looper thread ratio |

| 1 | Chain Stitch | 101 | 4.0 | 1 | 1:0 |

| 2 | Lock Stitch | 301 | 2.5 | 1 | 1:1 |

| 3 | Zigzag lock Stitch | 304 | 7.0 | 1 | 1:1 |

| 4 | Double chain Stitch | 402 | 5.5 | 1 | 1:3 |

| 5 | 2-thread over edge Stitch | 503 | 12.0 | 1 | 1.2:1 |

| 6 | 3-thread over edge Stitch | 504 | 15.0 | 1 | 1:5 |

| 7 | 4-thread mock safety stitch | 512 | 18.0 | 2 | 1:3.3 |

| 8 | 5-thread safety stitch | 516 | 20.0 | 2 | 1:1.34 |

| 9 | 4-thread covering stitch | 602 | 25.0 | 2 | 1:3.3 |

| 10 | 9- thread covering stitch | 606 | 32.0 | 4 | 1:3.5 |

4.9.3 MAKING MATERISL CONSUMPTION:

During the meaningful order negotiation process, concerned merchandiser must make an approximate material bill and costing. This should be updated as soon as order has been successfully negotiated and secured. Making material bill is an important function of merchandiser working with a garment factory.

Material bill is the detailed list of raw materials required to produce and ship a full consignment of buyer’s order for garments. Material consumption is required for detailed costing as well as for negotiating a placing order to supplier for purchase of raw material.

4.10 COSTING:

Costing means resources expended in production of product or garment. It is urgent to make a detailed costing of garments, because this is to be quoted to be buyer. A sample of costing sheet is given below:

Garment Costing Sheet (T-shirt)

| Style#: | P.O #: | Season | ||||||||||||||||||||||||||||||||||||||||

| Name of item | Description | Supplier | Quantity | Unit price | CostTK | |||||||||||||||||||||||||||||||||||||

| Fabric | 100% cotton | MilleniumTextile | 1.75 m | TK 70/m | 122.50 | |||||||||||||||||||||||||||||||||||||

| Interlining | Fusible | Stock | 16 cm | 20.00 | ||||||||||||||||||||||||||||||||||||||

| Sewing thread | Polyester | Costs BD Ltd | 150 m | 5.00 | ||||||||||||||||||||||||||||||||||||||

| Button | 18 ligne Poly | Tex Acc Ltd | 14 pcs | 2.50 | ||||||||||||||||||||||||||||||||||||||

| Care Label | Woven | 1 | 1.00 | |||||||||||||||||||||||||||||||||||||||

| Main Label | Woven | 1 | 0.75 | |||||||||||||||||||||||||||||||||||||||

| Size Label | Woven | 1 | 0.75 | |||||||||||||||||||||||||||||||||||||||

| Back broad | 12” ×18” | 1 | 2.00 | |||||||||||||||||||||||||||||||||||||||

| Neck broad | 1”× 18-20” | 1 | 1.00 | |||||||||||||||||||||||||||||||||||||||

| Gum tape | 1 | 0.50 | ||||||||||||||||||||||||||||||||||||||||

| Tissue paper | 1 | 0.50 | ||||||||||||||||||||||||||||||||||||||||

| Collar insert | Plastic | 1 | 0.75 | |||||||||||||||||||||||||||||||||||||||

| Price ticket | 1 | 1.50 | ||||||||||||||||||||||||||||||||||||||||

| Hang tag | 1 | 1.50 | ||||||||||||||||||||||||||||||||||||||||

| Poly bag | 1 | 2.50 | ||||||||||||||||||||||||||||||||||||||||

| Inner carton | 5 ply | 2.00 | ||||||||||||||||||||||||||||||||||||||||

| Outer Carton | 7 ply | 4.50 | ||||||||||||||||||||||||||||||||||||||||

| 169.50 | ||||||||||||||||||||||||||||||||||||||||||

Direct Labor Cost:

| Cost of materials | 169.50 | ||||||||||||||||||||||||||||||||||||||||

| Direct labor cost | 50.82 | |||||||||||||||||||||||||||||||||||||||||

| General & Admin overhead | 43.66 | |||||||||||||||||||||||||||||||||||||||||

| Total Cost | 263.73 | |||||||||||||||||||||||||||||||||||||||||

| Profit @ 15% | 39.56 | |||||||||||||||||||||||||||||||||||||||||

| Total: | 302.99 | |||||||||||||||||||||||||||||||||||||||||

| Selling price | 300.00 | |||||||||||||||||||||||||||||||||||||||||

4.11 Fabric finishing:

Fabric just coming out from oven or knitting machine can not be immediately used for dyeing or making garments. They need to be farther treated for the following reasons:

- They remain crude and coarse and do not have appropriate finish required of them.

- They have a tendency to shrink, to a very large extent, if not properly treated.

- Many grey-goods contain a large amount of sizing and starching materials which need to be got rid of before use.

- Besides, fabrics need to have better appearance before their dyed

- Fabrics need to under go different types of finishing treatment in order to incorporate divergent finishing requirements.

Types of fabric finishes:

- Preshrinking

- Sanforizing

- softening

- mercerizing and singeing

- water repellant

- resin finish

- skewing finish

- permanent press finish

- chintz finish

- water proof

- peach skin

- soil release

- fire retardant

4.12 Production system and layout:

Making machinery layout in different ways is a relevant to all types of production system. In the garments industry different production system dictates a different moods of machinery layout.

4.12.1 Defining layout:

Layout is actually an aggregation of work stations in which cut-pieces flow from machine to machine (operator to operator) and are sewn together and assembled into the desired dresses. Thus it is important to note that apparel or is parts flow from operator to operator in a layout.

4.12.2 Symbols and nations used for sketching a layout:

| Sl. no | Machine | Symbol | Sl. no | Item | Symbol |

| 1 | Lockstitch machine | 5 | Chute | ||

| 2 | Special Machine | 6 | Side Table | ||

| 3 | Iron & Manual Work | 7 | Operating | ||

| 4 | Press Work |

4.12.3 Classification of layouts:

Juki research institute classifies preliminary layouts into three categories:

- Layout by process

- Layout by group

- Layout by model

4.13 Garments Wash:

It is most important factor in textile sector. In different stages of production, various spot we found in products that are needed to wash. Various spot we found in products that are given below:

1. Oil spot

2. Dirty spot

3. Print spot

4. Fabrics spot

5. Etc

There are different types of garments wash used now a day. They are:

- Normal wash

- Pigment wash

- Bleach wash

- Stone wash

- Acid wash

- Enzyme wash

- Caustic wash

- Garment wash and over dye

- Whitening

4.14 Printing:

Printing is referred to as controlled placement of color, design, motive, pattern etc. on a fabric. Printing finds popular application both in knitting and woven garments. With printing, garments look colorful smart and beautiful.

The colorant is fast prepared in the form of a paste and applied on the fabric in various ways:

- Direct printing.

- Discharge printing.

- resist printing

- Transfer printing

- Flock printing

- Warp printing

- Pigment printing

- Lacquer printing

- Manual printing

- Roller printing

- Screen printing

14.15 Embroidery:

Embroidery is a decorative work created on apparel in order to enhance good look. It has now become very popular and widely used. Most of the order received generally has one or another type of embroidery work. Modern embroidery machines are fully automatic. Multi head embroidery machines are now more popular and used. All works are controlled and these machines attain high efficiency and productivity. Here a nine-needled embroidery machine is displayed.

14.16 PAYMENT MONITORING:

After getting order from buyer A L/C have to open by the buyer .L/C means Letter of Credit. It is a conditional undertaking of payment. It is a document issued by a bank on behalf of an applicant undertaking to make payment to a beneficial up to a stated amount of moneys within a prescribed time limit and design stipulated documents.

Types of L/C:

- Revocable L/C: This type of credit can be amendment or cancel by the applicant without only prior notice to the beneficial. Here all risks are involves for the seller but buyer has more flexible.

- Irrevocable L/C: This type of credit ca be amendment or cancel only to the agreement of all parties concern.

- Irrevocable & Confirmed L/C: This type of credit involves the undertaking of the advising bank in addition to that of issuing bank .It means that issuing bank request a 2nd bank to add its own confirmation to the credit .So that the confirmation bank is responsible to make payment if the issuing bank to pay the beneficiary.

- Transferable L/C: This type of L/C that is transferable as per the need.

- Back-to-Back L/C: This type of L/C can be against a valid expert L/C. Master L/C. It is so much popular in textile area.

** If we open a L/C then need some things that are given below:

1. Trade license

2. Memorandum Certificate

3. Membership certificate

4. IRC

5. TIN

6. Bond license

7. Insurance

8. Factory Insurance

9. Agreement with the house owner

** L/C Export Document:

1. C.O

2. Inspection Certificate

3. U .D

4. G.S.P

Benefits of L/c

Sellers End:

1. Without having cash payment

2. Guaranteed business without investing any cash involvement

3. Risk free

Buyers end:

1. Guaranteed business without investing any cash involvement

2. Without having cash payment

3. Risk free

4. Same with quality product. The buyer should be ensured that he would get the quality product.

Get The Feed Back:

*** The above flow-charts just an example. Buyer-to-Buyer it can be different.

14.17 Freight calculation:

International orders for garments are placed in FOB prices. So obviously freight is paid by the buyers at the port of destination. But still merchandiser or shipper must know how to calculate sea or air freight.

Containers are specially designed well build strong vassals to hold cargo for delivery by ship. There are three types of containers in use:

- 20’ containers

- 40’ containers

- 40’ Hi Q containers

Chapter-Five

FINDINGS & ANALYSIS

5.1 FINDINGS OF MERCHANDISING DEPARMENT OF SHAYA APPARELS LTD:

It appears that merchandising management is one of the key areas of garments sector. But unfortunately, in Bangladesh merchandising management planning and controlling is reported to be unsound I indicates that merchandising management planning and controlling is extremely poor in entire garments sector in Bangladesh, which in turns, has adversely affected the getting order from abroad. In practice, I see some problems when I investigate merchandising management system in Shaya apparels ltd Lack of proper communication of different level of department.

- Failed to follow merchandising management technique like buyer attention technique, sampling techniques, order delivery techniques etc. for what that reason it failed some time to determine target order quantit

- All the people are very helpful at Shaya Apparels ltd. Again some people use find they are agree to help me but did not agree to teach.

- There is no specific training and research department in Shaya Apparels ltd for internally develop employees and workers.

- Company should evaluate not only the responsibility of the merchandiser but also the efficiency of the merchandiser.

- In this company they (merchandiser) do not keep any record in the computer for further needed. They keep record only for present need.

- Pricing is the most important for better merchandising, but I do get a clear idea how they determine price. They are interest to know this to their junior merchandiser.

- Merchandiser still use old model computer for their communication.

- There is a no permanent marketing merchandiser of this company. Without marketing merchandiser a garments company do not get order from buyers.

- So it is very much necessary to control the discipline.

5.2. SWOT ANALYSIS OF THE COMPANY:

The SWOT analysis having identified the company’s internal strength and weakness as well as external opportunities and threats. We need to consider by previous marketing and other related analysis an overall picture has revealed of Shaya apparels ltd . It can develop new function business of corporate strategies to accomplish this change. A SWOT analysis is shown in the below:

5.2.1 Strength of the company:

Strength is the power of a company by using it a company may achieve the competitive advantage “.Shaya apparels ltd is a well reputed company in the textile industries of the country”. It is an enormous activity in the textile industry.

Here the existing strength of the company is mentioned as below:

- No loan from any bank

- A large amount of Assets.

- A well known reputed brand name.

- Good quality of product

- Well environment

- Management competence.

- Sound marketing skills.

- Good material management system.

- Availability of efficient and qualified human resources world latest.

- Appropriate organizational style.

- Appropriate control system.

- Good financial management.

- It has in-house power generation capacity is 150 kilowatts.

- Roads leading to the complex have been built by are maintained by Bengal Leisure wear Ltd

- Tube wells ensure an abundant flow of water.

5.2.2 Weakness of the company:

Weakness is the internal and existing limitation of a company for which it is unable to be many competitive advantages. Some weaknesses of the Shaya apparels ltd are –

- Lack of proper promotional program.

- Top management always pressure on lower management.

- Too much labor turnover rate

- Depends on fully foreign order.

- Developing people skill assessing process requirement text time.

- Integration of section output & input still need further co-ordination among the section.

- Poor security in store.

- Small capital

- Old model computer system that is very slow to work.

- No security in use of computer.

- So much Salary discrimination.

5.2.3 Opportunity of the company:

An inventorying opportunity is an area of seller head in which a company can perform profitable. The opportunities identified for the Bengal Leisure wear Ltd. are as follows:

Company can expand its product line by introducing differentiation or introducing new product.

- The good will and demand of these kinds of products are increasing data by day especially in the European market.

- Greater possibility to product diversification with quality.

- Supervisor and foreign technician live on site to provide 24-hour coverage.

5.2.4 Threats of the company:

Threat is an external obstacle or a barrier for which a company can’t achieve its predetermined goals. The major threats of this company are as follows:

It is mainly depend on own capital. It does not get any tax advantages.

- Govt. has given G.S.P (Generalized system of performance) facilities. But these facilities will continue only to 30th June 2005.

- Political unrest or instability is the threat of this company. Because of Hartal and political violence. Production is hampered and it cannot supply the product at the right time.

- Increasing foreign company’s domination.

- And most important threat war to one country to others.

RECOMMENDATION & CONCLUSION

6.1 RECOMMENDATION:

Garments sector plays a very important role to earn foreign exchange to our country. A large amount of foreign money comes from the exporting of Garments. However a large number of workers maintain there live on this sector, specially the women. So, government should take special nursing in textile sector. Some points are given to overcome the problems of merchandising of this sector:

The authority should gather adequate knowledge about merchandising.

- They should follow appropriate merchandising technique.

- Adequate training facilities provided for personnel for development. Should follow a specific inventory costing method, in the context of rising trend in raw materials price.

- They should determine yearly inventory cost like ordering cost, carrying cost acquisition cost separately.

- For purchasing raw materials, Shaya Apparels ltd. should follow acquisition procedure strictly.

- Shaya Apparels ltd. should analyze the balance sheet through various ratios for determining efficiency, profit-earning capacity, financial solvency etc.

- Shaya Apparels ltd. should develop merchandising system and strictly. They should determine optimum level of inventory.

- Sound communication should be established between managing directors to merchandiser. Steps to be taken to increase fire service equipment are to face any kind of accident.

- Cost control system must be implemented at every stage in the organization.

- Most of the officer has to motive to teach every employees and researcher of their own inspiration.

- A specific department for training and research, which will provide adequate training and research facilities for personnel for development.

- Every department will communicate their problem with other department of the company.

- Medical facilities should be improved.

- Effective personnel management should be set up.

- Proper steps should be taken to stop power failure.

- Various motivations will be provided to workers for sound production.

- Shaya Apparels ltd. should modernize their equipment for inventory.

- They should computerize their every level of inventory

6.2 CONCLUSION:

Today’s garments fully depend on merchandising. A good merchandiser can develop the quality of product and increase the sales of the product. Merchandising is a big job and is a complex one. It is so much important in our garments industry. The study “Merchandising system of Shaya apparels ltd.” revealed that garments of Bangladesh are fully depending on merchandising. . It may an honorable professional for educated persons. For developing garment sector merchandising management system will have to focuses on modern system. For the development of merchandising there are many factors involved. Merchandising plays an important role. The result of the study showing that there is lot of step for shaya apparels Ltd. to improve their merchandising management has certain implications for the business community as well as national merchandising planners. The study “Merchandising Management of Shaya apparels ltd. revealed that Merchandiser is most valuable human resources for the progress of the organization. For the development of these valuable resources there are many factors involved. To increase the productivity of an organization effectively, efficient merchandiser will have to develop. Preparation of future business managers should provide for the development of managerial skills relating to merchandiser function. Colleges and universities offering business administration curriculum would do well to evaluate their courses as they relate to the findings of this study. This direct study indicates the potential utility that could be derived from undertaking more comprehensive investigations covering only merchandising management of Bengal Leisure wear Ltd. There are consequent developments of newer knowledge can definitely contribut increase the efficiency of business management and this, in turn, will increase the satisfaction of all interested buyer parties, which will be the ultimate goal of business

increase the efficiency of business management and this, in turn, will increase the satisfaction of all interested buyer parties, which will be the ultimate goal of business