Rapid thermal processing (RTP) is a semiconductor manufacturing technique used to quickly heat and cool material in a controlled environment. It is a semiconductor manufacturing process that rapidly raises silicon wafer temperatures above 1,000°C for a few seconds. It is used to modify the properties of semiconductor materials for use in electronic devices. RTP typically involves heating a material to a high temperature for a very short period of time, usually just a few seconds or less, and then rapidly cooling it back down. Wafer temperatures must be gradually reduced during cooling to avoid dislocations and wafer breakage caused by thermal shock.

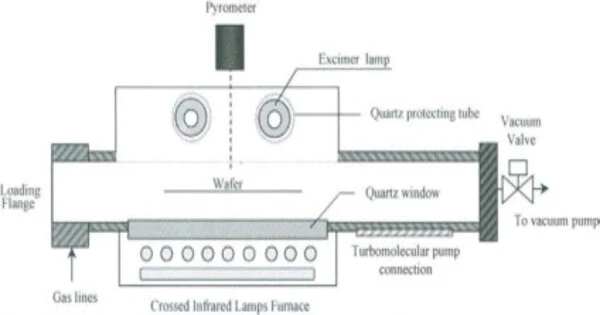

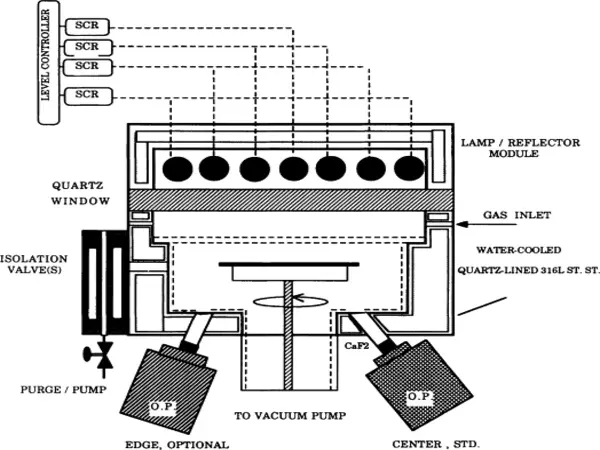

High-intensity lamps or lasers are frequently used to achieve such rapid heating rates. These processes are used in a wide range of semiconductor manufacturing applications, including dopant activation, thermal oxidation, metal reflow, and chemical vapor deposition. RTP is typically carried out using specialized equipment that can heat the material quickly and uniformly. This equipment typically uses a powerful light source, such as a flash lamp, to rapidly heat the material. The material is then quickly cooled using a process such as quenching or cooling with gas.

Advantages

RTP has a number of advantages over other thermal processing techniques. For example, it can be used to selectively modify the properties of specific areas of material without affecting other areas. This makes it particularly useful for fabricating complex semiconductor devices.

Temperature control

Accurate measurement and control of wafer temperature is one of the most difficult challenges in rapid thermal processing. Monitoring the ambient temperature with a thermocouple has only recently become possible because the high-temperature ramp rates prevent the wafer from reaching thermal equilibrium with the process chamber. In situ pyrometry is used in one temperature control strategy to achieve real-time control. Iron is melted for welding purposes.

Rapid thermal anneal

Rapid thermal anneal (RTA) is a process used in semiconductor device fabrication that involves heating a single wafer at a time to affect its electrical properties. Different heat treatments are created for different effects. Wafers can be heated to activate dopants, change film-to-film or film-to-wafer substrate interfaces, densify deposited films, change states of grown films, repair ion implantation damage, and move or drive dopants from one film to another or from a film to the wafer substrate.

Rapid thermal anneals are carried out by equipment that heats a single wafer at a time via lamp-based heating, a hot chuck, or a hot plate to which a wafer is brought close. They are shorter in duration than furnace anneals, processing each wafer in several minutes. To achieve short annealing times and high throughput, temperature and process uniformity, temperature measurement and control, and wafer stress are all sacrificed.

Applications

RTP is used in a variety of applications, including the fabrication of integrated circuits, solar cells, and other electronic devices. It is an important tool for the semiconductor industry and is widely used in research and development.