Introduction

Bangladesh’s garment industry is growing by leaps and bounds. Our country’s GDP has increased as a result of garment products. To be honest, this industry is significant in Bangladesh. Garment products have been one of the most important goods for importing in foreign countries. A large amount of foreign currency instead of these products has caused a radical change in Bangladesh’s growing economy. That’s all right. Bangladesh’s economy is being pushed by ready-made garments (RMG). Bangladesh exports RMG goods worth around 30,000 crore taka. This accounts for 75% of total export revenue.

Depending on the RMG sector, there are numerous small and large textile industries. Aside from cartons, buttons, strings, and similar industries, various types of trade and commerce such as a bank, insurance companies, transports, C & F, ports, and shipping are established. This industry directly employs approximately 25 lakh workers, 80 percent of whom are women. Another ten lakh people are employed in the textile and garment industries. As a result, approximately 1 crore people are directly and indirectly dependent on this industry. Of course, the majority of them are dragging a heavy load of family mouths with them.

Prospect of RMG Sector

RMG industry owners are scared right now. According to one International Trade Commission (ITC) report, China has taken the most appropriate position in the quota-free world since 2004. The following country will be India. Buyers in the United States will consider Bangladesh and Pakistan to be the top exporting countries for strategic reasons.

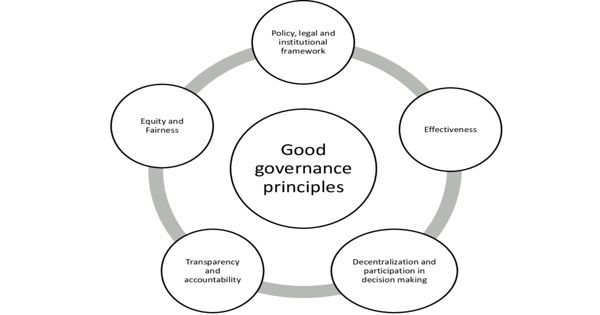

Since 2004, the developed, developing, and least developed countries (LDCs) have been competing the most. It is important to note that both developed and developing countries are among our main competitors. If we want to stand against all odds, we have to emphasize competitive price, quality standard of goods, time of serving goods, labor laws of the country and international labor law, bilateral and regional treaties, and so forth.

Bangladesh’s RMG sector is reliant on clothing imports due to a lack of a textile industry. Furthermore, the port charge is relatively higher than in other countries, and bank interest, commission, and other rates are also higher. Import and export of goods are delayed due to hartals, strikes, and other similar political causes. Goods transport is also expensive. If the government and associated business organizations worked together to solve the problems listed above, Bangladesh would have hardened and stabilized its position by 2005.

In today’s world, there is an air of bilateral and regional treaties. Bangladesh should try as well. In the meantime, has established good relations with ASEAN countries in preparation for the post-MFN period. Countries from BIMSTEC and the D-8 are also getting closer. This is a positive sign for Bangladesh’s RMG sector, as Australia, Japan, and other countries have expressed interest in investing in this sector. Norway, Canada, and New Zealand have granted the United States duty-free access to these countries. Except for EU countries, our RMG export is not particularly high. As a result, the countries that provided us with duty-free access should be evaluated as a new market with no lingering effects.

However, the recent Rana Plaza slide in Savar is a heinous blow to duty-free access to the United States. On April 23, 2013, Rana Plaza, which housed four garment factories, collapsed. The 9-story complex with 3222 workers (according to BGMEA) is now under ground; several traceless workers (approximately 800) have been leveled to the ground and about 2500 (excluding 400 dead bodies) have been rescued, with many of them still having addresses. Seeing such infrastructural flaws in our RMG sector, buyers from global markets have almost turned their backs on us. Dan Mazina, the US High Commissioner in Bangladesh, has already stated that Bangladesh may face a GSP problem as a result of this haphazard condition. Of course, he has also assured us that he will plead for us to the US buyers’ association, and it is a matter of hope for victimized Bangladesh.

It is also a source of great hope that the National Coordination Council (NCC) on textile and ready-made industries has recommended the establishment of Central Bonded Warehouses (CBWs) in export processing zones as well as a Tk. 3000 crore fund to meet the challenges of post-MFA. The high-powered committee also suggested that a textile zone be established with a ready infrastructure, similar to EPZs. More prescriptions include allowing the import of fabrics, grey yarn, dyestuff, garment machinery, and accessories via back-to-back letters of credit (L / Cs) and the re-export of unsold items from CBWs. If this suggestion is implemented, the day’s demand will be met. Again, the prospect of the RMG sector is directly involved with the solvency of the garment workers who are pertinent to be mentioned here.

Life of the Garment Workers

For a bright prospect of the RMG sector, the condition of the workers must be called into question. The workers do not know day and night. Most of them have been going on working almost standing all time. Besides overtime duty is compulsory. For the integral work in the confine of the stuffy factory, a worker becomes sickly. He/she often suffers from dyspepsia, anemia, and the like. He/she has to remain standing for most of her/his duty. As a result, he/she feels his/her legs heavy for deposited blood in them. He/she becomes fade. He /she has no uniform. They are simply dressed. Their dressing is a combination of patched clothes. They are an early riser. They usually get up at 5 a.m. and run to the workplace with a tiffin box in their hands. They usually live in very unhygienic slum areas.

Their drinking water is impure. Most of the workers are female. A lot of child laborers are employed in these factories. Many divorcees are working here. Female workers are sexually being harassed now and then. These are the negative sides for a garments worker. Above all, they are ill-paid instead of rib-breaking labor. Someone is still paid only 1500 taka per month whereas the minimum salary has been fixed Tk. 3000/month. Despite the flourishing period of the garment industry, they are drooping for continuous work day by day. But their pecuniary condition is unchanged. Again, Savar’s tragedy has appeared to them as another plague. Lots of fresh lives and fresh dreams have been buried under the ground. Lots of kinsmen (parents, spouse, sister, brother, daughter, son, beloved, and others) of the wounded, survivors, dead, and traceless have gathered around the ravaged Rana Plaza.

In the stinking of dead bodies in the air, they are questing back their darling persons in a pensive or vacant mood. Prime Minister and opposition leader including other political figures and general people are wordless; they are dumbfounded now. But alas! the main culprits behind this tragic note are still out of reach; they are also missing voluntarily. The untimely dropouts will never come again under this sun, their kinsmen will never wait for them to come. At last, the deprived rebounded by the wall behind have begun to rise, though very late. Now they know how to revolt against the capitalist owners, and such sign bids fair of the bright future of the RMG sector of the country. Of course, the govt. the side has come forward to compensate the destitute of the RMG sector.

Conclusion

Undoubtedly, hope and fear are at work in the weak minds of Bangladesh’s poor commoners, where 30 percent of the total population is unemployed, 40 percent live below the poverty line, and workers are neglected by owners. Again, fires in the garment industry are on the rise. Meanwhile, many garment workers have died in fires in various garment factories. Someone believes it is happening out of displeasure. Nonetheless, the mentality to overcome difficult obstacles, 25 years of experience, and cheap labor all point to a bright future for Bangladesh’s RMG sector.