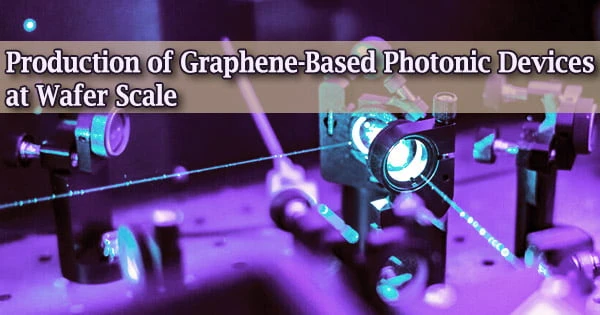

More than ever, the globe needs dependable communications. The size, cost, and particularly the power consumption of conventional equipment, which is directly tied to greenhouse gas emissions, are all constrained.

This could change with the introduction of graphene, revolutionizing broadband. Researchers from the Graphene Flagship have now developed a wafer-scale fabrication method that enables automation and large-scale production. This method relies on preset graphene single-crystal templates to enable integration onto silicon wafers.

This project, which appeared in the journal ACS Nano, is a fantastic illustration of the kind of cooperation that the Graphene Flagship ecosystem fosters. Many Graphene Flagship partner organizations, including CNIT and the Istituto Italiano di Tecnologia (IIT) in Italy, the Cambridge Graphene Centre at the University of Cambridge in the United Kingdom, and Graphene Flagship Associated Member and spin-off CamGraphIC, were expected to participate.

The construction of the graphene photonics integrated circuits was also done by researchers at the Tecip Institute in Italy and the third party with Graphene Flagship ties, INPHOTEC.

The Graphene Flagship promotes collaboration between academics and major industry to build high-technology ready prototypes and products, until they may achieve market exploitation, through the Wafer-scale Integration Work Package and Spearhead Projects like Metrograph.

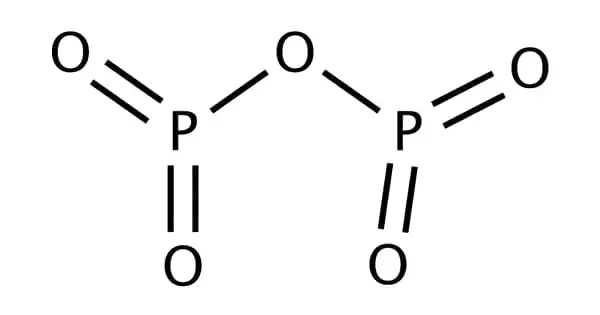

The use of single-crystal graphene arrays makes it possible to fabricate new materials.

“Traditionally, when aiming at wafer-scale integration, one grows a wafer-sized layer of graphene and then transfers it onto silicon,” explains Camilla Coletti, coordinator of IIT’s Graphene Labs, who co-led the study. “Transferring an atom-thick layer of graphene over wafers while maintaining its integrity and quality is challenging,” she adds.

“The crystal seeding, growth, and transfer technique adopted in this work ensure wafer-scale high-mobility graphene exactly where is needed: a great advantage for the scalable fabrication of photonic devices like modulators,” continues Coletti.

Traditionally, when aiming at wafer-scale integration, one grows a wafer-sized layer of graphene and then transfers it onto silicon. Transferring an atom-thick layer of graphene over wafers while maintaining its integrity and quality is challenging.

Camilla Coletti

Over 28 billion connected devices are predicted to exist in the world by 2023, the majority of which would require 5G. New technologies will be needed to meet these demanding specifications.

“Silicon and germanium alone have limitations; however, graphene provides many advantages,” says Marco Romagnoli from Graphene Flagship partner CNIT, linked third party INPHOTEC, and associated member CamGraphiC, who co-led the study.

“This methodology allows us to obtain over 12,000 graphene crystals in one wafer, matching the exact configuration and disposition we need for graphene-enabled photonic devices,” he adds.

The technology is also compatible with current automated fabrication technologies, which will hasten its adoption and use in the industry.

In another publication in Nature Communications, researchers from Graphene Flagship partners CNIT, Istituto Italiano di Tecnologia (IIT), in Italy, Nokia including their teams in Italy and Germany, Graphene Flagship-linked third party INPHOTEC and researchers at Tecip, used this approach to demonstrate a practical implementation:

“We used our technique to design high-speed graphene photodetectors,” says Coletti. “Together, these advances will accelerate the commercial implementation of graphene-based photonic devices,” she adds.

Photonic devices with graphene as a component have various benefits. Ultra-broadband communications are made possible by the light they absorb, which ranges from ultraviolet to far-infrared. The ultra-high carrier mobility of graphene devices allows for data transfer that is faster than the best ethernet networks and surpasses the 100 gigabits per second limit.

To offer more environmentally friendly solutions, it is essential to lower the energy requirements of data and telecommunications. Information and communication technologies currently account for about 4% of total greenhouse gas emissions, which is comparable to the aviation industry’s carbon footprint, which is expected to rise to around 14% by 2040.

“In graphene, almost all the energy of light can be converted into electric signals, which massively reduces power consumption and maximizes efficiency,” adds Romagnoli.

Frank Koppens, Graphene Flagship Leader for Photonics and Optoelectronics, says:

“This is the first time that high-quality graphene has been integrated on the wafer scale. The work shows direct relevance by revealing high-yield and high-speed absorption modulators. These impressive achievements bring commercialization of graphene devices into 5G communications very close.”

Andrea C. Ferrari, Science and Technology Officer of the Graphene Flagship and Chair of its Management Panel added:

“This work is a major milestone for the Graphene Flagship. A close collaboration between academic and industrial partners has finally developed a wafer-scale process for graphene integration. The Graphene Foundry is no more a distant goal, but it starts today.”