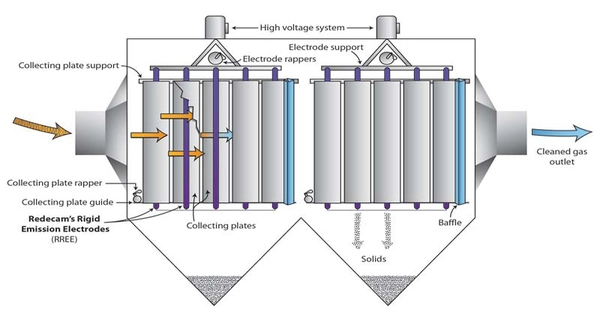

An electrostatic precipitator (ESP) is a device that reduces air pollution by eliminating particulate matter (dust and ash) from industrial and power plant exhaust streams. It is a filterless device that eliminates tiny particles, such as dust and smoke, from a flowing gas by utilizing the force of an induced electrostatic charge, which only slightly impedes gas passage through the unit. It is often used in industries that produce large amounts of airborne particles, such as coal-fired power plants, cement plants, steel mills, and other manufacturing facilities.

Unlike wet scrubbers, which apply energy directly to the moving fluid medium, an ESP applies energy solely to the particulate matter being collected, making it very efficient in energy usage (in the form of electricity).

Here’s how an Electrostatic Precipitator typically works:

- Particle Charging: The exhaust gas containing particulate matter is passed through a series of electrodes. In the first section, the gas passes through a region where high-voltage electrodes apply a strong electric field. This electric field charges the particles in the gas stream.

- Particle Collection: After being charged, the particles then pass through a collector section with oppositely charged plates (collecting electrodes). The charged particles are attracted to and deposited onto these plates due to the electrostatic forces.

- Particle Removal: Periodically, the collected particles on the plates need to be removed to maintain the efficiency of the system. This is typically done by rapping or vibrating the collecting electrodes to dislodge the particles, allowing them to fall into hoppers for disposal.

The advantages of Electrostatic Precipitators include:

- High Efficiency: ESPs can remove a high percentage of particulate matter from the gas stream.

- Low Pressure Drop: They typically have a lower pressure drop compared to other air pollution control devices.

- Versatility: ESPs can handle a wide range of particle sizes and types.

However, there are also some challenges associated with Electrostatic Precipitators:

- Maintenance: ESPs require regular maintenance, and the collecting plates need to be cleaned or replaced periodically.

- High Initial Cost: The initial installation cost of an ESP can be relatively high.

- Sensitive to Particle Resistivity: The efficiency of ESPs can be affected by the resistivity of the particles being collected.