In order to mitigate the unexpected environmental effects of growing the major row crops, such as soil erosion, fertilizer runoff, and greenhouse gas emissions, perennial grass should be strategically planted throughout corn and soybean fields.

However, farmers must find it profitable to return some farmland to prairie, which is why a team of researchers led by Lisa Schulte Moore, a landscape ecologist at Iowa State University, has been researching the most effective ways to convert harvested grass into renewable natural gas.

“We’re looking at existing markets where there is already a demand, use existing infrastructure to reduce costs of the energy transition and create wins in multiple categories. We want wins for farmers, wins for businesses, wins for municipalities and wins for society,” said Schulte Moore, professor of natural resource ecology and management and director of the Consortium for Cultivating Human And Naturally reGenerative Enterprises (C-CHANGE). “We can have great conversations about what could be, but unless it benefits everyone along these supply chains, it won’t happen.”

Schulte-Moore’s research team recently published two peer-reviewed papers that illustrate the win-win potential of the system by modeling the economic viability of grass-to-gas production in various contexts and from various angles.

“We have to be able to quantify how much energy we can produce and show it can be cost effective and environmentally friendly in order to replace natural gas with resources that revitalize sustainable agriculture,” said Mark Mba-Wright, an associate professor of mechanical engineering and one of the studies’ co-authors.

We have to be able to quantify how much energy we can produce and show it can be cost effective and environmentally friendly in order to replace natural gas with resources that revitalize sustainable agriculture.

Mark Mba-Wright

City-based scenarios

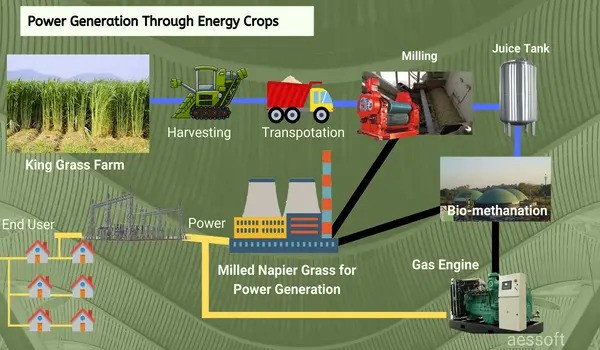

A $10 million federal grant in 2020, an additional $10 million in federal support in 2022, and roughly $650,000 from the Walton Family Foundation all contribute to the ongoing research. The goal of the project is to increase and optimize the use of anaerobic digesters. Anaerobic digestion, the organic matter’s natural biodegradation process without oxygen, releases biogas. Biogas can be captured in digesters that resemble tanks and converted into a fuel that can be readily substituted for natural gas derived from petroleum. It can also generate fertilizer and fuel electrical generators.

In a study published in BioEnergy Research, the Iowa State researchers modeled how a network of digesters in and around Ames could supply the city’s heat and power demands. Livestock manure, biofuel byproducts, food waste and wastewater would join grassy biomass as the feedstock supplies for up to 10 digesters. The locations, size and number of facilities depended on whether the network was designed primarily to produce natural gas or power.

The analysis found renewable natural gas was the most economically practical focus, with a levelized cost roughly twice the historical average price of traditional natural gas. Incentives supporting clean energy production could provide a boost to make pricing competitive. Regardless, seeing how digester supply chains would work to serve municipal needs helps city leaders envision possibilities, Mba-Wright said.

“We wanted to consider the seasonality of the supply and demand over a year to give a mayor, for instance, scenarios to look at and strategize around,” he said.

Researchers have discussed anaerobic digestion with municipal wastewater officials in several cities in Iowa, and generally they’ve been curious, said Schulte Moore, co-director of the Bioeconomy Institute and a 2021 MacArthur Fellow.

“Their immediate need is to provide a service to their customers 24-7. But they work on 15- to 30-year planning horizons, so they’re also thinking about the future,” she said.

A grass-to-gas road map

A study published in Global Change Biology Bioenergy estimated the economic and environmental impact of two hypothetical digesters that processed grassy biomass in the Grand River Basin in northwest Missouri and southwest Iowa.

According to the researchers’ study, over its expected 20-year lifespan, the digesters would provide a combined profit of more than $400 million under ideal conditions. The 45 million gigajoules of renewable natural gas generated over two decades, equivalent to around 12.5 billion kilowatt hours, would have an 83% smaller carbon footprint than natural gas obtained from fossil fuels. Emissions are also expected to be lower than those from corn-based ethanol and soybean-based biodiesel.

Most existing anaerobic digesters that produce renewable natural gas have run on dairy manure, so it’s essential to pencil out how they would perform on a grass diet, Mba-Wright said. “This is dotting our ‘i’s and crossing our ‘t’s to confirm the benefits are what we’d expect. We’re providing a road map to help build infrastructure, which will in turn reduce future costs,” he said.

The profitable scenarios studied in the study rely on existing carbon credit programs, such as the California Low Carbon Fuel Standard and the federal Renewable Fuel Standard. The most valuable outcomes necessitate high-yield grass and prairie restoration on some of the least productive cropland.

Researchers attempted to be as realistic as feasible in both research, accounting for all known costs, including capital expenses. However, they will become even more precise in the coming years as procedures improve and new research findings emerge, according to Schulte Moore.