Improving the Physical Distribution or Logistics Systems for ACI Mosquito

Coils During Peak and Semi-Peak Seasons

Advanced Chemical Industries Limited is a public limited company which was incorporated as ICI Bangladesh Manufacturers LTD. The principal activities of the company are to manufacture pharmaceutical products, consumer brands, public health and animal health products and to market them along with agrochemicals and other consumer brand items.

ACI’s mission is to enrich the quality of life of people through responsible application of knowledge, skills and technology. ACI is committed to the pursuit of excellence through world-class products, innovative processes and empowered employees to provide the highest level of satisfaction to its customers.

ACI Consumer Brands is a leading Fast Moving Consumer Goods company in Bangladesh. In mosquito repellent categories, this division has a very strong market share and position. ACI mosquito coil achieved 83% growth over 2004 and attained leadership position in the Green Coil market and is increasing the depth and width of the products and is becoming stronger in the market place paving the way for more introductions of mass market products in the future.

DEFINITION OF MARKETING LOGISTICS

Marketing logistic is rapidly becoming the most important aspect of business success. Marketing logistics is the practice of coordinating the flow of goods, services, information and finances as they move from raw materials to parts supplier to manufacturer to wholesaler to retailer to consumer. This process includes order generation, order taking, information feedback and the efficient and timely delivery of goods and services.

The physical distribution or logistics is a process-oriented system of purchasing, producing, and delivering product to customers. Its scope includes both internal enterprise processes and external business contributions from suppliers, transporters, channels and end-users. In other words, it refers to the analysis of and effort to improve a company’s processes for product and service design, purchasing, invoicing, inventory management, distribution, customer satisfaction and other elements of the supply chain.

Therefore, the marketing logistics or physical distribution involves planning, implementing and controlling the physical flow of goods, services and related information from points of origin to points of consumption to meet customer requirements at a profit.

NATURE AND IMPORTANCE OF MARKETING LOGISTICS

Marketing logistics or physical distribution typically started with products at the plant and then tried to find low cost solutions to get them to customers. However, today’s marketers prefer customer centered logistics thinking, which starts with the marketplace and works backward to the factory or even to sources of supply.

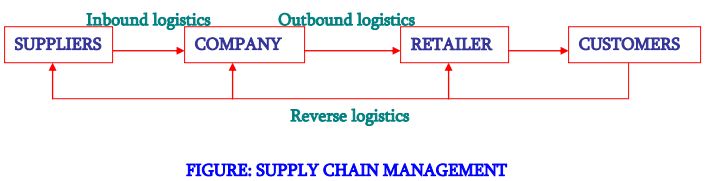

Marketing logistics involves not only outbound distribution (moving products form the factory to resellers and ultimately to customers) but also inbound distribution (moving products and materials from suppliers to the factory) and reverse distribution (moving broken, unwanted, or excess products retuned by consumers or resellers). That is, it involves entire supply chain management which means managing upstream and downstream value added flows of materials, final goods and related information among suppliers, the company, resellers and final consumers, which is shown by the following figure:

Thus, the logistics department’s task is to coordinate activities of suppliers, purchasing agents, marketers, channel members and customers. These activities include forecasting, information systems, purchasing, production planning, order processing, inventory management, warehousing and transportation planning.

In modern business and unfavorable competitive situations, companies are placing greater emphasis on logistics for several reasons.

- Companies can gain a powerful competitive advantage by using improved logistics to give customers better service or lower process.

- Improved logistics can yield tremendous cost savings to both the company and its customers.

- Improvements in information technology have created opportunities for major gains in distribution efficiency.

FOUR STEPS OF MARKET LOGISTICS

Market logistics planning has four steps:

- Deciding on the company’s value proposition to its customers. It includes standard delivery time and levels of attaining in ordering and billing accuracy.

- Deciding on the best channel design and network strategy for reaching the customers. It includes the channels of distribution, manufacturing facilities and warehousing facilities.

- Developing operational excellence in sales forecasting, warehouse management, transporting management and materials management.

- Implementing the solution with the best information systems, equipment, policies and procedures.

MAJOR LOGISTICS FUNCTIONS

Every company is ready to design a logistics system that will minimize the cost of attaining his own objectives. The major logistics functions include-

- Order processing

- Warehousing

- Inventory management

- Transportation

- Logistics information management

ORDER PROCESSING

Most companies today are trying to shorten the order-to-payment cycle- that is, the elapsed time between an order’s receipt, delivery and payment. This cycle involves many steps including order transmission by the salesperson, order entry and customer credit check, inventory and production scheduling, order and invoice development, and receipt of payment. The longer this cycle takes, the lower the customer’s satisfaction and the lower the company’s profits. Salespeople may be slow in sending in orders and use inefficient communications; these orders may pile up on the desk of order processors while they wait for credit department approval and inventory availability information form the warehouse.

WAREHOUSING

Every company has to store finished goods until they are sold, because production and consumption cycles rarely match. The storage function helps to smooth discrepancies between production and quantities desired by the market. In other words, the storage function overcomes differences in needed quantities and timing, ensuing that products are available when customers are ready to buy them.

The company must decide on how many and what types of warehouses it needs and where they will be located. The company might use either storage warehouses or distribution centers. Storage warehouses store goods for moderate to long periods. Distribution centers are designed to move goods rather than just store them. They are large and highly automated warehouses designed to receive goods from various plants and suppliers, take orders, fill them efficiently, and deliver goods to customers as quickly as possible.

INVENTORY MANAGEMENT

Inventory management also affects customer satisfaction. The company must maintain the delicate balance between carrying too little inventory and carrying too much. With too little stock, the firm risks not having products when customers want to buy. To remedy this, the firm may need costly emergency shipments or production. Carrying too much inventory is resulting in higher inventory and carrying costs and stock obsolescence. Thus, in managing inventory, firms must balance the costs of carrying larger inventories against resulting sales and profits.

The company can reduce their inventories and related costs through just-in-time logistics systems. Just-in-time systems require accurate forecasting along with fast, frequent and flexible delivery so that new supplies will be available when needed.

However, these systems result in substantial savings in inventory-carrying and handling costs.

TRANSPORTATION

Marketers need to be concerned with transportation decisions. Transportation choices will affect product pricing, on-time delivery performance and the condition of the goods when they arrive, all of which affects customer satisfaction.

The company can choose among five main transportation modes: truck, rail, water, pipeline and air and along with an alternative mode for digital products the Internet. But, for consumer goods in Bangladesh, the company can choose only truck and water way to deliver the product just in time. The company can choose or use intermodal transportation combining two or more modes of transportation at a time. In choosing a transportation mode for a product, shippers must balance many considerations, such as speed, dependability, availability, cost and others.

LOGISTICS INFORMATION MANAGEMENT

The company manages their supply chains through information systems. Channel partners often link up to share information and to make better joint logistics decisions. From a logistics perspective, information flows such as customer orders, billing, inventory levels, and even customer data are closely linked channel performance. The information can be shared and managed in many ways- by mail or telephone, through salespeople, via the Internet and the computerized exchange of data between organizations. So, the company wants to design a simple, accessible, fast and accurate process for capturing, processing and sharing channel information.

INTEGRATED LOGISTICS MANAGEMENT

Today the companies are adopting the concept of integrated logistics management. This concept recognizes that providing better customer service and trimming distribution costs require teamwork, both inside the company and among all the marketing channel organizations. Inside, the company’s various departments must work closely together to maximize the company’s own logistics performance.

Outside, the company must integrate its logistics system with those of its suppliers and customers to maximize the performance of the entire distribution system.

CROSS FUNCTIONAL TEAMWORK

In most companies, responsibility for various logistics activities is assigned too many different functional units- marketing, sales, finance, operations, purchasing.

Each function tries to optimize its own logistics performance without regard for the activities of the other functions. However, transportation, inventory, warehousing, and order-processing activities interact, often in an inverse way.

Lower inventory levels reduce inventory carrying costs. But they may also reduce customer service and increase costs from stock outs, back orders, special production runs, and costly fast- freight shipments. Because distribution activities involve strong trade- offs, decisions by different functions must be coordinated to achieve better overall logistics performance.

The goal of integrated supply chain management is to harmonize all of the company’s logistics decisions. Close working relationships among functions can be achieved in several ways. The company can create permanent logistics committees, made up of managers responsible for different physical distribution activities. The company can also create management positions that link the logistics activities of functional areas. The important thing is that the company must coordinate its logistics and marketing activities to create high market satisfaction at a reasonable cost.

LOGISTICS PARTNERSHIPS

The company can work with other channel partners to improve whole-channel distribution. The members of a distribution channel are linked closely in creating customer value and building customer relationships. The company can also make coordination with their logistics strategies and forge strong partnerships with suppliers and customers to improve customer service and reduce channel costs. The company can also use the third party logistics providers for delivering the products efficiently. These types of providers integrate logistics systems and perform any or

all of the function required to get their clients product to market.

FLEXIBILITY AND CHANGE

A strategic value-chain perspective requires that managers in the market-driven company regularly review the adequacy of their channels strategy and consider the impact of major market and technology changes. Changes in distribution may improve both customer satisfaction and organizational effectiveness. This perspective emphasizes the entire value chain and the company’s strategic positioning in its markets rather than short-term cost savings. It also requires that managers incorporate new distribution and communications concepts into their channel design where this provides competitive advantage.

FLOW CHART OF DISTRIBUTION SYSTEM

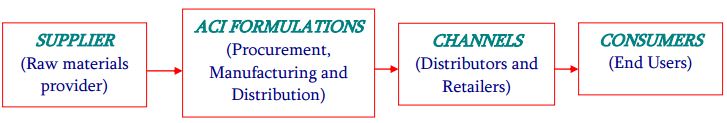

The aim of distribution is to manage supply chains, that is, value added flows from the suppliers to ultimate users to, as follows:

Thus the logistical task of ACI is to coordinate the activities of suppliers, agents, marketers, channel members and customers.

CURRENT SCENARIO AND PROBLEMS

Every company must decide on the best way to store, handle and move their products and services so that they are available to customers in the right assortments, at the right time and in the right place. Physical distribution and logistics effectiveness has a major impact on both customer satisfaction and company costs.

The ACI Company maintains strategically located sales centers in nineteen different locations across the country. It has developed an advanced distribution system through its 325 skilled and trained manpower under the supervision of

National Sales Manager, and 8 Zonal sales Managers and 58 Area Sales Managers. The distribution system is capable of handling continuing volume of diverse range of products from the various businesses through 206 distributors in Bangladesh.

Some companies state their logistics objective as providing maximum customer service at the least cost. Unfortunately, no logistics system can both maximize customer services and minimize distribution costs. Maximum customer service implies rapid delivery, large inventories, flexible assortments, liberal returns policies, and other services-all of which raise distribution costs. In contrast, minimum distribution costs imply slower delivery, smaller inventories, and larger shipping lots-which represent a lower level of overall customer service.

The goal of logistics should be to provide a targeted level of customer service at the least cost. The ACI company must first research the importance of various distribution services to customers and then set desired service levels for each segment. Therefore, the company must weigh the benefits of providing higher levels of service against the costs for ACI Mosquito Coils in peak and semi peak periods.

This study would develop and improve the physical distribution systems for delivering ACI mosquito coils in the said distribution point. The activities in maintaining or managing the long term exchange relationships have investigated a range of issues including concentration of potential buyers, cost per contact, opportunity for dialogue and customer relationships, personal relationships, developing company image, decision making process and the exchange relationships.

Although the study will make some contributions to understanding the causes of cost effective and efficient logistics management system and will minimize the lack of comprehensive study for exploring and examining the factors that responsible for maintaining the exchange relationships.

While training here as an internee I have found some hidden problems. Now I will try to highlight these problems and later on try to give a solution to the respective problems.

- Adoption of improper ways in collecting orders.

- Use of Excess Distributors

- Lack of cross functional teamwork.

- Improper truck route planning.

- Ineffectiveness of distribution department.

- Lack of transport vehicles.

- Lack of inventory management.

- Lack of information management.

- Preparing Incorrect Invoice.

- Lack of notification from the ACI Formulations.

- Dissatisfied distributors

ADOPTION OF IMPROPER WAYS IN COLLECTING ORDERS

In ACI, Sales supervisors send Demand Drafts or Pay Orders when they get orders from the distributors and on the basis of their primary target. Here the distributors demand the products from all over the country at any time they wish for. There is no general routine for each district to be catered for. Hence, the company’s transport may have to be sent in one region for more than once. Even if the order is small the company has nothing to do but give in to the call and this becomes an unnecessary financial burden. The company has to constantly reorganize its schedule according to the incoming orders. Furthermore, during peak and semipeak seasons this unorganized way of taking orders and carrying them out is a waste of the company’s time and money.

USE OF EXCESS DISTRIBUTORS

ACI company strategically uses 206 distributors in Bangladesh to distribute ACI Mosquito Coils which seems to be a large number. Here, I found some distributors who actually demand a very small amount of Mosquito coils. Distance between some of the distributors is not that much. Larger number of distributors in a specific area means that cost for loading and unloading the goods increases. Time is also an important factor to note as most of it is spent in this unnecessary manner.

Since the truck authority charges for each stoppage for unloading the products, it is not monetarily feasible for the company.

LACK OF CROSS FUNCTIONAL TEAMWORK

Every business needs a cross functional teamwork which facilitates the whole system to deliver the products. But the ACI consumer brands did not take any step to formulate a cross functional teamwork in a cost effective way. In the process of delivering the finished goods, the data entry officer collects DD through fax from the Business Floor. Since he is not always present near the fax machine, it is not possible to receive the fax in time. In peak and semi peak seasons this becomes an even more acute crisis.

After entering the data he submits the papers to Dhaka Depot for raising the invoice. And it takes time to raise each invoice especially when they come in a haphazard manner. Finally he sends the invoices to distribution department to arrange the truck planning. There is a lack of coordination between the distribution department and the consumer brands. The consumer brand does not get any direct support from the distribution department. This is due to the fact that sometimes the consumer brands and the distribution department do not collect the actual information about the stock of the mosquito coils and the related bonuses that are provided from the ACI Formulations, Gazipur. Thus the consumer brands have to face a lot of problems in coping up with the demands of the distributors.

IMPROPER TRUCK ROUTE PLANNING

There is the lack of a route plan in delivering the products, for the distribution executive does not follow a structured route. They deliver the products in a conglomerate way that is even if there is a drop off point about a few kilometers off the main route, a second transport is sent instead of the first one going a bit off course. And the transport agency arranges a route according to its own will. This poses a threat to the time limit as the product may not be delivered to the distributor on time. Some distributors do not get the product within 10 days from the invoicing date and as a result the responsible sales supervisor and area sales manager makes telephone calls to the distribution department. This increases the expenses as well as the time and hence none can achieve their monthly target.

INEFFICIENCY OF DISTRIBUTION DEPARTMENT

Generally, the distribution department is the concerned party to deliver the product at the distributors point. They are doing a good job. But I observed some flaws in delivering the product to the said points. Sometimes sales department gives an extra pressure to deliver the products since they have a target to reach. It happens so that may be they arrange a truck loading of only 250 to 300 cartons instead of the regular full capacity of 650 cartons for Sylhet, Lalmonirhat or Barisal area.

LACK OF TRANSPORT VEHICLES

ACI has only 6 covered vans for distributing the mosquito coils in the whole of Bangladesh. But this is insufficient for the distribution of the products at the right time and at the right place. And the company also does not have any specialized workshop to maintain the trucks in case of a breakdown and as a result the company faces a great problem in meeting the deadline for the distribution of the products.

LACK OF INVENTORY MANAGEMENT

For fulfilling the demand of mosquito coils during the peak and semi peak seasons the availability of the product is an important element. In the peak and semi peak seasons the mosquito coil users demand more coils from the distributors. As a result, the distributors give a lot of orders to the company within a very short period of time. If the company fails to meet the production then the whole process is affected by the short supply of the mosquito coils. In the month of August the company did not deliver ACI Mosquito Coils 14’s due to the short supply of the product. Due to lack of information management, raw materials and poor production capacity, the company lost its market share in the repellant mosquito coils sector.

LACK OF INFORMATION MANAGEMENT

Every company needs a strong information system that delivers the right information at the right time. The factory does not send daily report to the consumer brands on the amount of stock present. The internet server sometimes goes off and the telephone connected with the factory goes dead as well. These are some of the reasons why the consumer brands were unaware of the short supply of the product due to improper maintenance of the information system. The MIS made the mistake of entering the wrong price in the invoice and hence creating a misunderstanding between the distributors and the company.

PREPARING INCORRECT INVOICE

I found a wrong invoice in Dhaka Depot. The distribution department sent Vanish in place of Air Freshener due to wrong invoicing. Similarly price at 11.25 TK was labeled at 16.50 TK for ACI Mosquito coils (Green) and hence creating a huge racket among the distributors since they got less than what they had paid for.

LACK OF NOTIFICATION FROM THE ACI FORMULATIONS

When an invoice is sent to the factory, the factory may fail to meet its requirement at that time. Hence some products may not be delivered on time at the distribution point. This may happen when the product is lost from the factory or the transport.

The factory also fails to report this fact to consumer brands division because it does not have to. The consumer brands can only find this out when the distributor complains of not finding its required products. This produces a hassle for the consumer brands division as they can not give any immediate solution to the problem.

DISSATISFIED DISTRIBUTORS

After the distributor has delivered the products to the retailers, some of the products might be damaged or deteriorated. In this circumstance retailers return the products to the distributor. ACI collects these damaged products after every 6 months or so. Therefore, part of the distributor’s investment gets caught up and remains dormant. This arouses certain dissatisfaction among the distributors and creates a distance between the company and the distributor. In this situation the distributor tends to order fewer amounts of products to maximize his liquidity. In addition to this each distributor gets 3.5-4% commission on the total amount being sold. Nowadays distributors are complaining that this amount is not up to their expectations.

RECOMMENDATIONS

CONSTRUCT PROPER WAY IN COLLECTING ORDERS AND PROCESSING

For delivering the right products both at the right place and at the right time the company needs to construct a structured order collection process. If the company’s sales supervisors submit their orders within a deadline fixed by the company then it makes the distribution process effective and efficient. Along with this the company must keep a fixed date for each of the deliveries made each month. From my observation I propose some points in order processing.

Let me given example of how this can be done. The company has charted out some specific date fixed for some regions of the country. The company develops a route planning on the basis of geographical and other characteristics i.e. on the basis of the salespersons primary target and previous sales trends of ACI Mosquito Coils during the peak and semi peak seasons. Each route must have specific dates in a month and the transport will not go in any other date apart from those. Special consideration will only be made if any distributor demands more than 550 cartons at a time and delivery can be made on that occasion even if that is not the date for that distributor’s route.

The distributor must fax or courier the demand drafts or pay orders to ACI Centre within 1.15 pm for a specific area on his allotted date. The company will receive these demand drafts and process these within 2.00 pm so that the transport authority can set off for the factory and simultaneously the logistic officer will receive the list of the products by fax to sort out. By 3.00 pm the transport will reach the factory and at the same time the logistic officer will be ready to load the products given prior in the list through the fax.

The ACI Formulations will load the truck in accordance to the destinations sequentially so that the products for the initial destination can be found near the gate and the products of the later destinations at the back. To protect the cartons from rain water ACI Formulations must pack the bulk products with polythene sheets and after the delivery the transport authority must return the polythene sheets to the ACI Formulations to be used in the next delivery.

This practice will enable the distributor to maintain regularity in sending for and receiving products on time. This will result in the fact that the distributor will lose less time in delivering the product and at the same time get their products on time.

Hence the company will benefit substantially in both goodwill and financial terms.

SCRAPPING EXCESS DISTRIBUTORS

On studying the market and the distributors I have seen that the process rivals of ACI use lesser distributors than ACI. Since the excess distributors are so close to each other only the distributor with the highest coverage should be selected. There is no need to overcrowd a single place and moreover pay for it. Previously I named three distributors in Daudkandi, Homna and Chandina respectively. The positions of these three distributors are situated just like the vertices of a triangle. If we can get a distributor right at the center, it could serve the needs of these three places all at the same time. This means that the distributor being chosen must be financially solvent and must have the roaming capacity to cater for all these three places. The distribution process will be more cost effective and the selected distributors will be satisfied as one will eventually get a higher commission than three separate ones.

From my observation point it is feasible to have 130-140 distributors rather than the regular 206. The extra payments of unloading the goods at each drop off point will substantially be reduced and if all the savings are added up, the sum will surely be monumental.

NEED FOR CROSS FUNCTIONAL TEAMWORK OR COORDINATION

All the relevant employees connected with order processing must be based on one floor. Hence time will be saved and better communication will be established between the employees. Each employee must be responsible for himself and the others working with him and hence minimizing the chances of making a mistake.

Finally, cross functional teamwork guides the entire organization toward providing superior customer value.

EFFECTIVE USE OF TRANSPORT VEHICLES

The company current has 6 covered vans, two of which are always out of order. To minimize transportation cost the company needs 8 covered vans which must be always in top condition. 2 of them must be used to cater for Dhaka City and the remaining 6 must work all out over the country. Two things should be pointed out here. First of all a fully equipped garage with experience mechanics must be kept at all times to keep the trucks in full swings. Secondly, an eye must be kept on the truck drivers so that they deliver the products and return on time. Disciplinary action must be immediately taken whenever any type of neglect is found on their

AVAILABILITY OF INVENTORY

During peak and semi peak seasons the company gets many orders which comes in rapid succession. If the company does not keep the inventory prepared to deliver the products immediately then slowly the daily distribution routine gets jam packed. In order for the product to be delivered as quickly as possible the factory must have the raw materials and all the factors related to production ready before each demand reaches the factory. The products must be in a stand by position at all times so that the distributors don’t have to wait too long. Stock must be kept ready at least a fortnight before any demand reaches the factory.

TRANSPARENCY OF INFORMATION MANAGEMENT

The factory must send daily report to the consumer brands on the amount of stock present. Therefore the consumer brands can predict the delivery date and notify the distributor. Also the modes of communication must be fully up to the mark so that no time is wasted while trying to get information through to each other. Each second wasted means that another delivery being late. And to send the right information at the right time is also important otherwise for sending the wrong information the time is being wastage.

EFFECTIVELY PREPARATION OF THE INVOICES

For preparing the incorrect invoice the distribution system is hampering to deliver the product and it creates a specific problem and finally affects the sales of the product. ON 19/9/12 the data entry officer got a DD from Ullapara but the Dhaka Depot did not prepare an invoice in favor of the distributor and after 6 days the distributor claimed the product but the distribution department did not get any specification to deliver the product. Therefore, for minimizing these types of problems the company can make a cross functional teamwork and also take some punishments for the responsible person.

REQUIRED PARTNERSHIP RELATIONSHIP WITH THE DISTRIBUTORS

For overcrowding the distributors the company is facing the problems to deliver the right product at the right place on time. So, it needs to minimize the distributorship. As a result, the company can observe all the distributors easily.

And the distributors who maintain the specified procedures they can achieve 4.5-5% commission as their performance level. And, to minimize the distributors’ dissatisfaction the company can replace the deteriorated products for four times in a year. Finally, by practicing the standard and specific route planning they are capable to handle all the situations effectively and they are also aware of the delivery time that when they get the products, as a result they will unload the truck with a very short period of time and the truck is going to next distributions point on time. Therefore, it reduces the dissatisfaction level of the distributors and hence the company can achieve their objectives by fulfilling the demands of the distributors.

CONCLUSION

Although many company state that distribution objectives is to provide goods at right time for the least cost. Unfortunately this provides little actual guidance. No distribution system can simultaneously maximize customer service and minimize distribution cost. Maximum customer service implies huge distribution cost. Whereas from my experiences I came to know minimum distribution cost implies cheap method of delivery and transportation system.

If all the departments of the company work closely and maintain the proposed recommendations effectively then the company can make a cost effective distribution system and finally achieve its own objectives.