During my dissertation period I have tried my best to highlight the overall organization Professor according to the suggestion and advice my supervisor Ms. Jesmin Akter, Assistant Professor Department of Business Administration, ASA University, Bangladesh.

Garments Sector is a well-known export oriented organization in Bangladesh. At the beginning of the dissertation program Z.M. Arafat, HR Executive, East west Industrial park Ltd. gave me the” opportunity to work different departments of the organization to L prepare a report on.

This report has been prepared at the end of the Dissertation period.

Purpose of the report:

The need of the study in the present context is very important because of the competitions that are for both international and local company. A number of brands are all ready exist in the market. Therefore it is obvious for a marketer to adopt suitable marketing strategies.

The prime objective of the Dissertation program is provide prospectively Post graduates with on the job exposure and an opportunity to apply theoretical knowledge so far received into real lifesituation and objective of the Dissertation report is to meet the requirement for the degree of MBA.

Specific objectives of the organization part of this report are as follows: –

- To have an overview of the Garments Organization.

- To find the Garments organization profile and departmental procedure

- To identify the corporate culture of garments industry.

- To have a detail knowledge of the activities of Management system of Garments industry.

Global marketing is changing rapidly and market is becoming too much competitive. So as time goes on, market becomes very competitive in nature. In this situation any marketing decision should be based on market information and consumer perception. This report deal with the export and marketing Practices of garments industry.

Objective:

The objectives of this report are as follows:

- To assess the market demand of the Garments product.

- To evaluate performance of Garments Sector

- To evaluate buyer perception about the product.

- To assess strength, weakness, opportunity and threat

Scope of the study:

This report will generate information in all the areas of marketing aspect. I have given more emphasis on sales & marketing department and its relative activities. This report coverage the following areas of

Product:

- Market size in terms of product variety.

- Market strategy on the basis of market share.

- Consumer perception before choosing a product sample.

Price:

- Consumer perception about price.

- Price of different brand product.

Promotion:

- Consumer promotion activities prevailing in the market

Methodology

Methodology is the process of collecting data and information. Methodology is the process, which is concerning with findings tools for best possible solution of problems. In this part of report, I have use or followed the following procedure to collect data and details information regarding the report.

Study Design:

At first I have formulated a plan for collecting data and then I have made a design on accounts of the project. Designing a research is essential for the study project. Here I set the place, organization, and person from where or whom I will get data and also set the pursuing method of collecting data.

To accomplish useful outcome, I have tried my best to design my study so that I could collect most accurate data.

Data Collection:

I have collected the following data:

- Primary Data.

- Secondary Data.

Primary Data:

It is the normal procedure of interviewing some people individually to get a sense of how people feel or think about the topic question. The main reason for collecting primary data is to bring new idea about the topic and since the existing information is not enough.

Method of Collecting Primary data:

- To collect primary data by face top face contact with the high official of Garments Sector.

- Inspected and visited to the related field.

Secondary Data:

Secondary data are those, which exist already somewhat, and they are gathered for specific purpose. These types of data’s are more quickly, available and economy. Data of this category are less to the biases.

Method of Collecting Secondary Data:

From web side and the annual report of Garments industry.

Nature of Garments Industry:

Garments Industry is a 100% export oriented organization. It is generally producing different kinds of Garments products and related materials in support of garments products. The products of garments organization are exporting all over the world.

Background of Garments Industry:

Bangladeshi garments Industry is the largest industrial sector of the country. Though the history Readymade Garment Industry is not older one but Bangladeshi clothing business has a golden history. Probably it started from the Mughal age in the Indian subcontinent through Dhakai Musline. It had global reputation as well as demandable market around the globe especially in the European market.

After industrial revolution in the west they were busy with technological advancement & started outsourcing of ready-made garments to meet up their daily demands. Many LDC’s took that chance & started ready-made garments export at that markets. An LDC Bangladesh took this chance enjoyed quota & other facilities of them. Thus ready made garments industry started to contribute in our economy from late eighties (1977). The history of the garments industry dates back to 1977 when the first consignment was exported to then West Germany by Jewel garments. The number of units, however, remained a meager 46 until the end of 1983. From a humble beginning the sector has thus made phenomenal growth over the last two decades, the number of units growing to around 4500. The RMG industry achievement is noteworthy, particularly for a country plagued with poor resource endowments and adverse conditions for industrialization. Exports increased from approximately 32 million US dollars in 1983/84 to 1.4 billion dollars in 1992/93. In 1987/88, the RMG export share surpassed that of raw jute and allied products. The figure further rose to 5.7 billion dollars in 2003/04, representing a contribution of about 75 percent of the country’s total export earnings in that year. The employment generated by the sector is estimated to be around 1.5 million workers. The readymade Garments Industry is the key export-earning sector for Bangladesh, which brings to this developing country $6 billion yearly revenue. The industry has over 4,000 export oriented factories and thousands more small-scale sub-contractors which employ nearly three million workers most of whom are women (80%). It is the biggest contributor to the country’s foreign exchange- around 76 percent- and employs around 2.2 million people, 80 percent of them women. The export figure of Ready Made Garments (RMG) reached US$ 9.2 billion in 2007 and there are predictions of it rising to US$ 12 billion or more in the next two years The garment industry of Bangladesh has been the key export division and a main source of foreign exchange for the last 25 years. At present, the country generates about $5 billion worth of products each year by exporting garment. The industry provides employment to about 3 million workers of whom 90% are women. Two non-market elements have performed a vital function in confirming the garment industry’s continual success; these elements are (a) quotas under Multi- Fibred Arrangement1 (MFA) in the North American market and (b) special market entry to European markets. The whole procedure is strongly related with the trend of relocation of production. It has been reveals that the tendency of low labor charges is the key reason for the transfer of garment manufacturing in Bangladesh. Bangladesh Garment Sector and Global Chain The cause of this transfer can be clarified by the salary structure in the garment industry, all over the world. Apparel labor charge per hour (wages and fringe benefits, US$) in USA is 10.12 but it is only 0.30 in Bangladesh. This difference accelerated the world apparel exports from $3 billion in 1965, with developing nations making up just 14 percent of the total, to $119 billion in 1991, with developing nations contributing 59 percent. In 1991 the number of workers in the ready-made garment industry of Bangladesh was 582,000 and it grew up to 1,404,000 in 1998. In USA, however, 1991-figure showed 1,106.0 thousand workers in the apparel sector and in 1998 it turned down to 765.8 thousand.

Some Garments Factory in Bangladesh:

- East west industrial park ltd.

- Board Bazar, Gazipur.

- S.B Knitting Ltd.

- Savar, Dhaka.

- Monde Apparels Ltd.

- Kallyanpur, Dhaka.

- Abedin Garments Ltd.

- Motijhel C/A, Dhaka.

- Agaco Fashion Ltd.

- Dohs, Gulshan, Dhaka.

- Ahmed Garments Ltd.

- Mirpur-1, Dhaka.

- Al-Musum Garments Ltd.

- Malibagh Chowdhury Dhaka.

- Albiun Appards Ltd.

- DIT Road, Malibag, Dhaka.

- Alpha Kniting Wear Ltd.

- Kawran Bazar, Dhaka.

- Ameo Fashion Ltd.

- Rampura, Dhaka.

Mission of Garments Industry:

To achieve and maintain a position of world class manufacturing and to build good relationship with buyers.

Objective of Garments Industry:

- 100% Safety record.

- 100% Delivery in time

- 100% Quality first time.

- 100% Commitment

- 100% Utilization of resources.

Principles of garments Industry:

- To deal fairly, openly and honestly with all employees, customers, and suppliers, buyers

- To combat corruption whenever and wherever it occurs.

- To value and support each other contribution

- To ensure equality of opportunity for all and discrimination whenever or wherever it occurs.

- To obtain the best value from the resources available.

Market Destination of garments Industry:

Garments sector has a large market in Furope with their plentiful fashionable designs. Branded products of the organization are also in good demand both in Asian and African Markets.

So toe market destinations are as follows:

- USA

- Canada

- Africa

- Europe

- Japan

Global Business Outlook of garments Industry:

Region | Country | Activates |

| Far East | Korea, Japan, China, Honk Kong, Taiwan | Market development, material sourcing and manufacturing. |

| South East Asia | Bangladesh, Thailand | Manufacturing sourcing with along term outlook of market. |

| North Amerca, Caribbean and central America | Miami, Seattle, Jamaica | Market development, manufacturing, and material sourcing. |

| Europe | Switzerland, Italy, Argentina, Norway, Chille, Belgium, Scotland, Etc. | Market development and material sourcing. |

WO ER’S RIGHTS AND RESPONSIBILITIES

Any industrial establishment or factory needs the worker’s awareness of rights and responsibilities. Some legal rights and responsibilities of garments sector for the workers are given below:

WORKERS RIGHTS DIVIDED INTO TWO PARTS

Legal Rights: Some legal rights as per BEPZA instructions are below:

- Minimum salary/Wages to be given.

- Workers shall not work beyond 10 Hours a day and 60 Hours a week including overtime.

- Without special permission form BEPZA authority no female workers are allowed to work after 8:00P.M.

- For excess work, payment will be as per rules.

- Management may not misbehave with the workers.

- Record attendance of working hours properly.

- Basic pay/allowance to be paid as per rules.

- A worker may be requested to work in festival holidays, but in lieu of that, compensatory leave or salary must be paid to that worker.

- In order for a worker to be dismissed for reasons of misconduct, rules and regulations must be followed.

Human Rights:

When working in the factory the following human tights are to be observed:

- To provide satisfactory working environment.

- To provide workers eyes, hands or part of body through protective devices where necessary.

- For any accident, emergency medical service or first aid to be provided.

- To keep sufficient lights in floor or room.

- To provide exits for emergency evacuation.

- To provide adequate safe drinking water facility.

- To provide hygienic toilet facility.

- For dangerous machines, to provide proper safety equipment to ensure safety.

*Masks for fiber and down work

*Metal hand gloves for cutting work

*Goggles for buttonhole or attaching machine work.

WORKER’S RESPONSIBILITIES

- Attend punctually in work place

- Abide by company’s Rules & Regulations.

- Participate in production process and endeavor to achieve target.

- No absence from work place without proper permission.

- Keep self and work place neat and clean.

- Careful use of toilet, commode and basin and keep clean for other’s use.

- Keep clean canteen area while eating food. Use fork and spoon. Do not waste food in the canteen.

- Obey supervisor and management instructions.

- Use identity card and uniform.

- Clean your machine before starting operation.

- After the working day necessary things must be deposited to issue girl.

- Do not remove scissors, bobbin case or other accessories from the factory premises.

- Do not talk unnecessarily on the production floor.

- Be attentive to work.

Incentives and Annual Increment Process:

- If any worker in any month is not absent for a single working day then he/she will get Tk. 100.00 as attendance bonus.

- Form time to tie other incentive bonus may also be given. Annual increment is given in accordance with BEPZA instructions.

- Special increments also may be given to those who have demonstrated extraordinary experience or skills.

FACILTTIES:

Provident fund: Every permanent worker is eligible to be a member of this fund. Every month 8.33% of basic pay is deducted from each member and an equivalent amount form the company will be deposited to the Provident fund account. A separate Trustee Board controls the fund, and is registered as per law. As per trustee deed deposited amount shall be returnable with interest. After a definite period of time, loan may be granted.

Lunch: Company provided lunch at a low cost. (Tk.2.00 per meal is charged).

Festival bonus: 2(two) Festival Bonus shall be paid to workers in each year. This bonus is paid before festival (e.g. EID). Each bonus is equivalent to one month basic pay.

Medical: Company provides free medical facilities to the worker. Normally one doctor and two nurses for every 1000worker.

Leave encashment: Any worker who does not enjoy portion of earned or leave not granted as per rules, may encase such earned leave in the following year.

Some Major Departments of Garments Sector:

Sales & Marketing Department

Sales & Marketing department is playing a vital role in working with the core area of garments Sector business with various respective buyers. Sales & Marketing department has to share there activities all other relevant department and sister concerns of garments industry. There are some other major departments of garments sector in Bangladesh which are as follows-

| HRD | MMCD | Quality Control |

| GSD | Medical | Quality Assurance |

| Sales | Technical | Import |

| Counseling | Work Study | Commercial |

| MCD | CAD | Accounts and Finance |

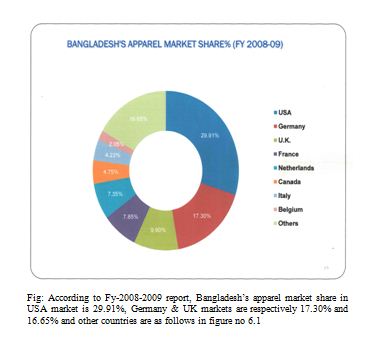

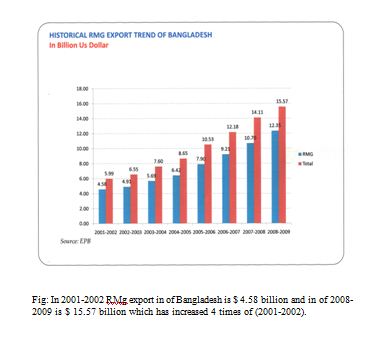

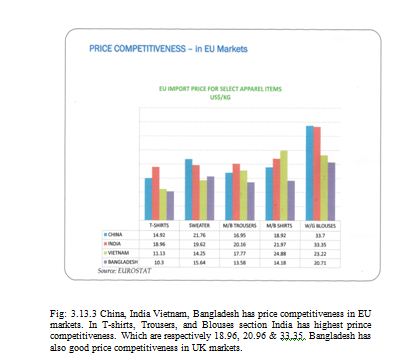

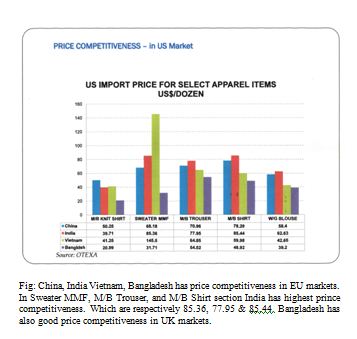

Some Graphs of Garments related activities:

BGMEA

BGMEA is one of the largest apparel exporters’ trade bodies in Bangladesh. BGMEA started its journey in Dhaka in 1983 with only 134 members and now the number of members of BGMEA is 4925.

BGEMA set up its regional office in Chittagong in 1985 considering its strategic importance being the port city and the gateway for all RMG exports.

EFFORTS TOWARDS BETTER SOCIAL ENVIRONMENT BGMEA

has its own compliance cell with 39 officials trained by brand buyers like Wal-Mart, SEARS, Carrefour, Hennes & Mauritz (H&M) and ILO

Health Center & Hospital: BGMEA runs 12 health centers with its own resources in Dhaka and Chittagong. Through these centers garment free treatment and medicine forgarment workers.

Mandatory Group Insurance: BGMEA made Group Insurance scheme mandatory for the garment workers working in the Member factories in May 2002.

Labor Arbitration: BGMEA started free labor arbitration facilities for garment workers in 1998 under the chairmanship of a retired judge

Mandatory Building Code: BGMEA made mandatory for all its Member factories to follow the Building Code

EFFORTS TOWARDS BETTER ENVIRONMENT

Fire and Safety Cell: BGMEA has established a fire and safety cell in 1997 to tackle the fire related emergency problems.

BGME Institute of Fashion & Technology (BIFT): Offers degrees in fashion and Merchandizing.

Human Resource Skill Development: Provides training to unskilled people and place them in the industry. Till now 15.000 people were placed.

Promotion of Reproductive Health Awareness, program on Gender equity & women & empowerment is run in collaboration with UNFPA \

Scholarship and Stipend program: To encourage primary education for the workers children BGMEA has been providing stipends to the meritorious meritorious children of workers.

Free Schooling: BGMEA is running three free schools for the workers, children and spouse of the RMG sector.

Free Eye Camp: To mark the Would Sight Day-2009 BGMEA in association with Grameen phone, IslamiaEyeHospital and Sight savers International organized free eye camps for the garment.

Product Category:

Product is a good, service, or idea, including all the tangibles and intangibles provided in an exchange between buyer and seller. Generally products can be divided into the following categories. They are:

- Consumer product

- Shopping product

- Industrial product

- Specialty product

- Convenience product

Consumer product: A good or service used for personal or family consumption that are consumer product.

Industrial product: A good or service used by an organization in producing other goods or services or in carrying out its operations.

Convenience product: Inexpensive goods and services that consumers buy often, without much thought or effort, are convenience products.

Shopping products: Consumers will expend time, effort, energy to find and obtain some goods and services. Buyers comparison-shop for these; thus they are known as shopping products. Consumers gather information about different brand and styles, visit different stores, note prices, read advertisements and consumer guides, and consult family or friends.

Specialty products: Goods and services that have specific attributes desired by a particular group of consumers are known as specialty products.

Interpretation: From the above discussion of product category we can say that the garments industry of Bangladesh is producing industrial predict. So the product of garments industry is garments product.

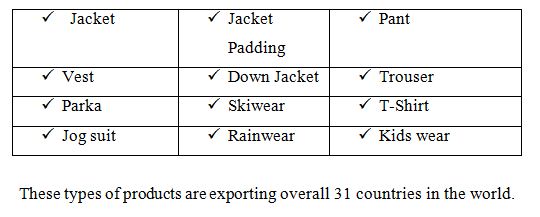

Products of Garments industry: There are 35 types of garments products of garments industry in Bangladesh. Which are as follows?

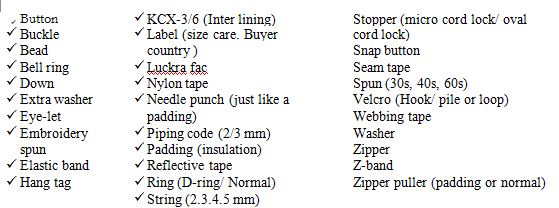

Garments materials:

Garments materials:

Terms of garments:

Terms of garments:

AppliqW: A pattern or shape applied to the surface of another material for decoration, frequently of a different type and shade of material.

Back rise: The distances between the crotch and the center back of the waistline. Back tacking: Fro and back stitching at the beginning or end of a seam to secure stitching.

Backing: Alien material attached or sewn on the under side part of a garment.

Bar tacking: To secure by stitching at stress points such as pocket comers, seam, ends and belt loops.

Bias: Across angle to warp and weft.

Box pleats: It is formed by folding material alternately in opposite directions. Button stand: The distance between button center and the stand edge of buttonhole.

Cloth: A principal or outside textile fabric of a garment.

Coat: Outerwear with sleeves, buttoned in the front.

Collar:

- Neck band of a shirt, coat and dress etc.

- Part of a garment that fits around the neck.

Cuff: The lower part of the sleeve of a shirt or coat at the wrist.

Dart: A wedge or diamond shape removed from the surface of the garment part by stitching or by cutting and stitching to the shape of the garment.

Draw cord.• A cord, which is used to gather a garment. A cord is usually passed through a channel.

Dummy:

A padded human shaped frame, usually mounted on a pedestal.

A tailors or dressmakers stand for fitting clothes.

Face side: The side of a material intended to be shown outside whilst in wear. Facings: Separated material used to cover specific areas of a garment such as a lapel. Flap: A shaped material, which covers a pocket mouth, or is for decoration.

Front rise: The distance between the center front of the waistband and the crotch.

Fullness: The extensive materials joined at a seam so as to create the desired shape in a part of a finished garment.

Fusible interlining: An interlining, which is having special treatment so that it adheres to other materials by the application of heat and pressure.

Gimp: The thread, which is used to support and rise the buttonhole stitching.

Grading: The process of producing different sizes of pattern from a master pattern.

Grain: Warp direction of the fabric.

Impression: Uneven surface owing to off pressing, usually around areas of extra thickness, such as pockets and seams.

Inlay: An extra seam allowance inside the garment for letting out if required or for strength at a given position.

Interlining: Alien material inserted in specific parts of the garment, usually between the inner and outer fabric for shape retention, strength, warmth or bulk.

Jacket: Short sleeved coat.

Knife pleat: The pleat which folds and face in one direction.

Lapel: The upper part of the front edge of a jacket or coat, which folds back onto the forepart.

Ligne: Unit of measure for buttons and ribbons, equal to 0.63 5 mm.

Lining: Layer of material added to the inside of the garment.

Linking: Loops of two knitted garment parts are run on to series of regularly spaced points and then

Model: The mold up garment made up from a design.

Monofilament thread: Continuous filament treads.

Molding: To shape the garment pr garment parts by the application of heat and pressure.

Multifilament thread: Thread contains numbers of individual, continuous filament.

Needle damage: Material damage caused by needle during sewing.

Needle gauge: The distance between needles on a multi-needles sewing machine.

Notches: Guides for garment assembly. It’s usually are small cuts made on the edges of garment parts.

Openness: The provision for leg stance in the angle of the leg seam.

Over-edging: The use of over-edge stitching either by hand or machine to bind the edge to avoid fraying.

Pad: Foam, rubber or other materials inserted into a garment for the purpose of shape or fit.

Pattern: A shape of a garment usually cut out in paper to use as guideline for making the garment.

Piping: Narrow cord like material with or without a filling, used to ornament the edges of some garments.

Placket: Opening of a garment. Different material is usually applied to that opening for style feature or reinforcement purpose.

Pleats: Material folds serve the purpose of expansion or style feature.

Quilting: The production of a padded effect by stitching or other means in two layers of materials lined with wadding or similar material.

Seam allowance: Seam margin between the edge component part of the garment and the seam line.

Seam grin: Gaping of a seam under stress grinning due to inadequate thread tension at sewing.

Seam pucker: Unwanted material puckers or catches along the line of stitching.

Seam slippage: The movement of warp and weft threads away from a seam line under transverse stress.

Tacking: To reinforce garment part by hand stitching or machine.

Top stitching: Explosive stitching sewn on a seam. Mainly used as reinforcement or decoration.

Trimmings: Garments accessories apart from the main material and sewing threads. Waistband.• A band on a garment fitting around the waist.

Yoke: Part of garment fitting around the shoulder seams, usually to chest level.

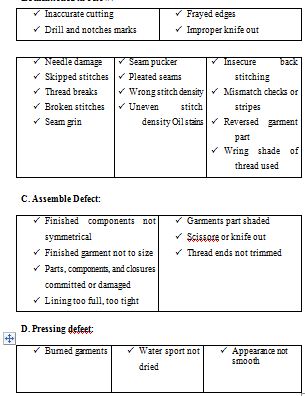

Defects of Garments:

In production process a garment may posses several defects. Some of these defects are mentioned in below:

Introduction:

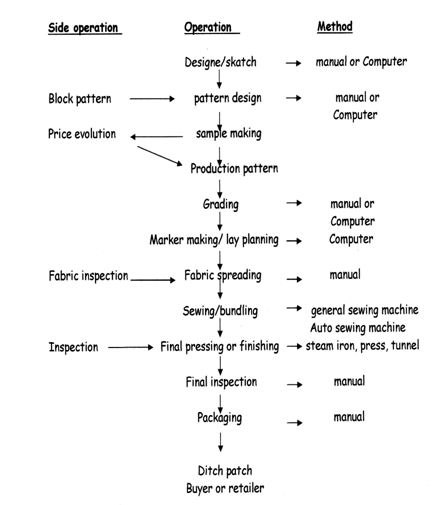

Garments mainly manufacture in two bases: Tailoring basis and industrial basis. Industrial basis garments are manufactured by taking standard body measurement of man and women for a particular design and different sizes. Garments manufacturing sequence can be shown in the following way:

Pattern making:

To prepare accurate shape of every part of garments on a board paper is called pattern. Different pattern are made for every parts of the garments. These patterns are used over fabric or marker paper to sketch every part of the garments before cutting.

Preparing pattern for garments require efficiency, technical knowledge, design analysis power and the efficiency on garments manufacturing technology. Pattern in industry are prepared mainly in two steps-which are called block pattern and garments pattern.

Sample garments making:

Sample garments making:

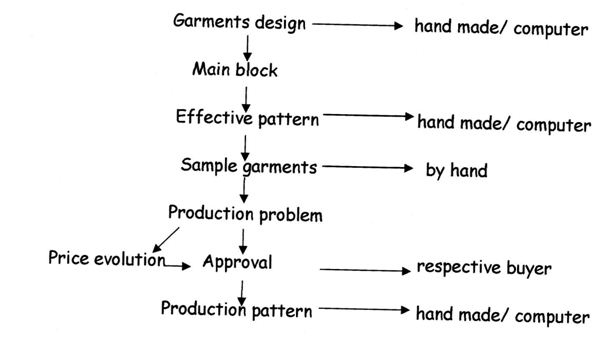

In industrial sector every garments is produced for business purpose. As for thousand of pieces garments are produced for every style. Before producing every style, it needs to make a sample garments which broadly depends on the condition of the buyer. The hierarchy of making sample garments is as following:

Marker making:

Generally the term marker implies a pieces of paper on which every pattern of every sizes are sketch in such way so that the lowest amount of fabric cam be wastage. The width of marker is taken as same as minimum fabric width and the length of marker is depended on how much sizes of a garments pattern would be used on the marker.

Marker is based on the patterns supplied by the pattern section. The markers are made by a team of marker men aided by the technical department and CAD (computer aided design). A crucial point to be noted while making markers is that the consumption of fabric per garment should be as minimal as possible without compromising on the structure and quality of the garment.

Preparing marker with computer requires input all pattern into the computer memory. For inputting all patterns into computer memory generally digitizing or scanning method is used. Computer marker maker generally used computer skin, key-board, and light pencil. Marker maker then gives some instruction like marker width, pattern, check making etc. In this system computer can make marker by itself and this marker is called automatic marker. Most efficient marker can be obtaining through this method. When marker maker prepare marker through computer it is called interactive marker making.

Marker, which is making by computer, is more effective and quality than the marker prepared by manual system. Marker by computer can save at least 2% fabric but its primary cost is costly. Though marker which is made by computer, it has various opportunities.

Fabric spreading

In garments industry fabrics are cut at a time for a lot of garments. According to production plan and length and width of fabric decorating fabric is called fabric spreading. Based on the length of the marker, the fabric rolls of the same shade are laid by a team of 4 to 6 helpers. Each lay will be of a length of approximately 13 yards and will be around 3 inches thick. The 3 inch thickness may contain anything from 80-250 plies of fabric depending upon the type of fabric used. A team of lay helpers can be expected to lie between 30-55 plies per hour depending on the fabric and whether the fabrics have checks or not. During spreading fabric we have to remember the following things:

- Correct ply direction

- Elimination of static electricity

- Easy separation of the cut lay into bundles

- Avoidance of fusion of plies during cutting

- Avoidance of distortion in spread

- Matching checks or stripes.

There are two methods are used to make lay by spreading fabric:

Manual method

- Spreading with the help of hook

- Spreading with the help of hand playing spreading track

Mechanical method.

- Semi-automatic machine

- Full – automatic machine

Cutting section:

Work in cutting section starts with making marker and after the laying is done. The cutting is done by a team of 2 cutters who used cutting machines to cut the different parts of the garments. They are helped by 2 workers who segregate the parts and take them to the numbering section for numbering. Notch cutting machines and band knife machines are also used for certain specific cutting jobs.

Each part of a garment is numbered with the name number, so that when the garment is stitched there is uniformity in the shade and measurement of the different parts. This is done with the help of a hand held numbering machine, which uses small labels with adhesives. Each helper in the numbering section can number about 2000 pieces per hour.

After the numbering is done, some of the parts like the collar, cuff and front placket have to be fused with interlining on the fusing machine.

The next step is to bundle the numbered and fused parts for sending to the sewing lines. The bundles are done in lots of garments from 25-50 pieces depending on the parts of the garment. Each bundle will contain all parts of the garments and the numbers will be in sequence. Now the goods are ready for sending to the sewing line and the cutting section hands over the goods to the allotted sewing line.

Sewing section:

Sewing is most important part in manufacturing a garment. Generally sewing means attaching fabrics with needle and thread. Each sewing machine operator or helper in the line will be doing only one or more operations on a garment and then pass it on to the next operator for doing another operation.

Each sewing line is made up of different types of machines like-The single needle,

- Double needle,

- Over lock,

- Lock stitch machine,

- Chain stitch machine

- Flat stitch machine

- Blind stitch machine

- Button holing machine

- Button attaching machine

- Bar tack machine

- Zigzag stitch machine

Kansai and feed of the arm. The sewing line is normally divided into the input and output section and each will have a supervisor. The overall charge of the sewing line is the line in charge and line chief that is wholly responsible for the proper working of his line.

Before starting a new style, a technical meeting is held and decided types of needles to be used, how the stitching is to be done etc. The maintenance department sets up the machines based on these details and the technical team helps the supervisors to solve the technical problems while starting a new style.

The cut parts brought from the cutting section are supplied to the operators in trolleys for ease of movement and the trolleys are moved from operator to operator in the sequence of the operations.

The main role of the supervisors and line chief consists of the following:

- Ensuring that inputs are available from cutting section for continual production.

- Using the right operator in the right operation to ensure maximum productivity as each operator’s skill and expertise vary from the other.

- Balancing the workflow to ensure that there are no bottlenecks where the goods get stuck.

- Ensuring that each operator in his section produces the garments with the right quality.

- Coordinating with the quality, technical and finishing sections to solve problems

- Ensuring that production targets are met

- Accounting for each garment which has been input into the line

- Controlling the workers in the line, taking care of their leave,

career development and developing a personal report with them.

After the garment is complete at the end of the line, the quality of the garment is checked by quality controllers and after that the passed garments are handed over to the production accounting department who are the record keepers of production.

Washing Section:

All garments are necessarily not washed. It depends on the buyer’s requirement and perception of the way the finished product should look and feel like. Garments are washed in a lot with various chemicals like detergents, enzymes and softeners to meet the wash standards required. After the garments are washed in a washing machine, hydro extractors take out the excess water and then driers are used to dry the washed garments.

Ironing:

The garments are ironed using steam irons. The ironing also might involve light, medium or heavy ironing with or without steam depending on the fabric, buyer’s measurement specifications and the area of the garment, which is being ironed.

Finishing Section:

The job of finishing section is to thoroughly check the garments again for defects whether in presentation, sewing or measurements. Their primary job is to check the inside of the garments and pass the garments, which satisfy the quality standards set.

Final quality controller is the last stage of quality checking to ensure that the final QC has done his job satisfactory. The final quality controller checks the garment in full for defects and presentation.

Packaging

The folder man folds the QC passed garments according to the specifications of buyer. They attach the price tag and any other tags, which are to be attached to the garments.

The packing man uses cartons with marking as per buyer’s specifications to pack the garments. Each order also indicates the ratio in which the goods are to be packed as size, color ratios and the packing has to be done according to these ratios.

After packing the goods, the supervisor and the final QC are expected to inspect the garments and take full responsibility for the goods packed. The cartons are numbered and then a final packing list is made after approval by the sales department awaiting inspection by the buyer for final dispatch.

Some Photograph of Garments Sector: There are some Photograph of Garments related activities and product.

SWOT Analysis:

SWOT Analysis:

Generally we make SWOT analysis to know the organization overall position. Through this analysis we could be able to know the organizations‑

S = Strength

W = Weakness

0 = Opportunity

T = Thread.

Strength:

Competitive Price

International standard Quality Control process

Bangladesh has 30 years of experience in garment manufacturing.

Superiority in the lower end niche, as well as handful of suppliers doing brand items.

Rapidly developing backward linkage industry

Increase in direct sourcing by the brands through local offices at Dhaka.

Bangladesh is the 3rd largest apparel exposing country in the world

Wide geographic coverage and distribution

Good and familiar working environment –

Strong computerized technology –

Excellent distribution and sales network-

Presence of human resource department –

A good number of efficient and satisfied workforce

Minimizing any harmful or hazardous impact on the environment

Has long-term commitment to its buyers, clients, associates and employees.-

Established quick communication system among the branches to branches, departments to departments by using LAN, intercom system, Internet, fax, and on phone.

Using modern and expensive technology like SAP software, video conferencing, computerized digital camera etc.

The organization provides strong job safety to its employees

Weakness:

Skill and experienced workforce are continually leaving the organization due to not getting expectable payment.

Existing miss communication to the mid level employees, basically in evaluating their performance.

Opportunity:

Duty free export of goods in the zone.

GSP facilities available for export to USA, Europe, and Japanese markets.

Local and international Banking facilities are also wide open.

Re location of industries from one zone to another within the country is perrmissible.

Re location of industries from abroad are allowed.

Customs office. post office, medical office, fire station, police station is within the zone.

Duty fee export of goods produced in the zones.

Exemption of income tax on borrowed capital.

Getting inexpensive work force comparing among the world.

Getting quota facilities.

Threat:

- New competitors have entered in the market and coping market share gradually Strong competitors are maintaining marketing research process and analyzing the market share and influence target buyers.

- Going out skillful workers from the organization may cause great harm by providing the learned policies of the organization and so on.

- Basically, in Bangladesh aspect politically instability (hartal, strike, karfio etc) is one of the great problems for any sorts of business.

Recommendation

Three months are short time to know about garments industry of Bangladesh I have tried my best on the basis of my little knowledge. The garments organization should implement more challenging reward and appraisal structure for its employees. Price should be more competitive with best competitors because the challenger can attack the leader by launching innovative product and superior product.

Garments industry is a well-known organization in our country and it has made a revolution in marketing of garments appliances. Garments organization is exporting heist quality product expanding their sales and marketing network.

After analyzing the whole process of garments moments manufacturing it becomes clear that extreme competition is going on in the market and the competition is mostly based on quality.

Conclusion:

Garment industry is controlled by the transfer of production. The globalization of garment production started earlier and has expanded more than that of any other factory. The global economy is now controlled by the transfer of production where firms of developed countries swing their attention to developing countries. The garment industry of Bangladesh has been the key export division and a main source of foreign exchange for the last 25 years. Many people have earned their livelihood through this industry. Their may be gender discrimination, low wage level exist in the garments industry, but still, they supply employment for all of theses people who come here to live. The Ready Made Garment industry in Bangladesh is made up of 3,486 manufacturers and accounts for 76% of total foreign exchange earnings. It employs about 180,000 managers and 1.5 Million workers, of whom 1.2 Million are women. In Bangladesh, the RMG industry has emerged as a major economic sector and has had its impact on the financial services sector, communications, transportation, and on other related industries. The RMG industry has had a major social impact. It has empowered 1.2 million women with employment and economic independence, which in turn has earned for Bangladesh recognition as a modern and enlightened society.

From the Above discussion we can say that Garments Industry is a well know export oriented industry in Bangladesh. We earn many foreign currency from Garments Industry in Bangladesh. So we should take care of Garments industry for our long run.