Introduction:

Merchandising is the methods, practices and operations used to promote and sustain certain categories of commercial activity. This is the art or buying or selling the products or merchandise.

In Bangladesh, the concept of merchandising mostly refers the apparel clothing merchandising. Here the merchandise is the finished packed garment which could be tops or bottoms in formal wear, casual wear or intimate wear, also keep in consideration for home textiles, terry towels etc.

In merchandising, your role could be buying the merchandise or selling it to your buyer to keep live the supply chain.

- Merchandisers are serious in the success of any garment retail business.

- They provide the right products at the right time, enabling a company to match with latest market trends and meet the market demand. In the merchandising concept, time management is a gig to manage one’s time properly, so s/he can focus on value adding actions.

The Merchandiser

An individual, who acts as a coordinator, follows-up and takes total responsibility of an order form booking to shipment and beyond, for the customer who placed it and for his company’s management.

Duties & Responsibilities of Marketing Officer:

Dealing with the buyer & convincing the buyer is the main duty of marketing officer. A marketing officer also has some other duties.

The main duties & responsibilities of a marketing officer are given bellow-

- To prepare cost sheet by dealing with the buyer.

- To take different steps by discussing with the high officials & merchandisers.

- To maintain a regular & good relationship between commercial officers & merchandisers.

- To maintain communication with the buyers and buying houses.

- Communicate with better knowledge of the products.

Actually the responsibilities & duties of marketing officer begin from getting order of buyer & ends after receiving payment by the buyer. So, he should be always smart, energetic & sincere.

Merchandising Management system:

Buyer sends an order copy by e-mail or sometimes swatch also.

E-mail is taken hand from (Order copy)

The measurement of various parameters are inserted by coding number in the order copy like-

- Quantity of garments,

- Yarn type,

- Count,

- Fabric type,

- Color,

- Body measurement,

- Shipment date etc.

- Before ultimate order a development sample is sent to buyer.

- Then OK the sample then price is executed.

- After getting the order then a color lab-dip is done

- Lab-dip is approved

- Sampling is carried out.

- The sample is sent to buying house to check.

- After approved the sample then accessories

- and fabrics are booked.

Finally shipment is done after all clearance.

The merchandiser basically follows up with all concern production departments for their ordered products.

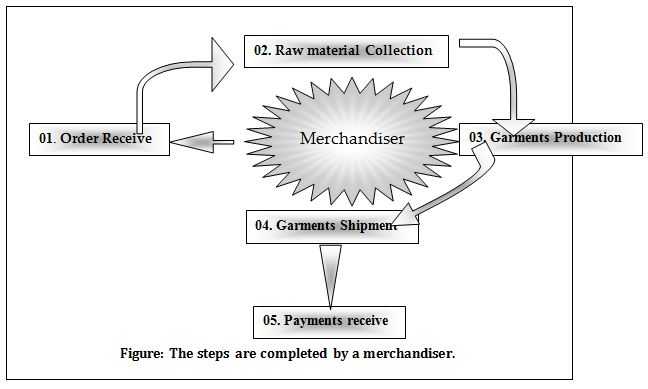

The major functions/steps of a merchandiser:

- Procuring the garments order.

- Procuring the raw materials.

- Production of garments.

- Shipments of garments.

- Receiving of payment for garments.

The steps are shown as diagramacally:

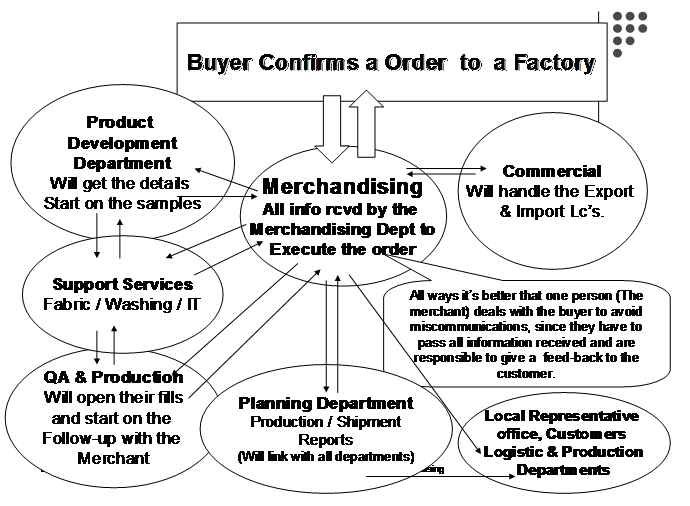

Buyer Confirms an order to a Factory

Production planning and pre production meeting:

- Initial planning is prepared by the merchandising department when the order confirmed.

- Based on the sample approval and shipment date, the production department makes the planning of the production only.

- The planning is done following the styling of the product and the machine lay out to calculate the number of pieces production per hour.

- Before production commence, pre production meeting is necessary with all concerned departments to get the correct productions.

Production: sample development, planning, quality control and inspection (AQL)

Quality Control and Inspection [AQL]:

- Customer wise the quality requirement will get vary and merchandisers are responsible to communicate with customers to get the correct quality requirements and need to co-ordinate with factory quality control department so that they will well understand the requirement and can take care of the bulk productions.

- Inspections are done during production which is called in line inspection. Later the final inspection done by the factory QC as well as buying office QC to make sure that the final products is shipping with right quality.

- Mentioned that, the right quality not good quality as the ‘quality’ refers to customer’s requirement.

Costing/Pricing

- Costing is the principal task of any merchandisers.

- Methods of Pricing:

- Calculate the fixed and variable costs associated with the product.

- Also below cost elements need to consider during costing.

~ Pricing for Fibers & Yarns

~ Pricing for fabric manufacturing

~ Pricing for garment manufacturing

~ Cost of accessories

~ Commercial cost

~ Break even point

~ Consumption of fabric and accessories with wastage percentage.

~ Total cost analysis [how much does it cost to provide merchandise to end customer

Standard, Measurement spec sheet/Product pack

Standards are provided by the customer and it could get vary from customer to customer.

Merchandisers need to study the standard very carefully.

If any issues with any part of customers standard, this need to be share with customer before order confirmation

Each style will be briefed with a product pack and all necessary information will be mentioned there along with measurement sheet.

Example: If the tolerance limit in measurement specs is too low compare to production feasibility, merchandisers need to inform this to buyer before order confirmation and need to settle down the acceptable tolerance limit by both parties.

Commercial

- LC: Letter of Credit- Once the order is confirmed, buyer’s bank issues a Letter of Credit (LC) to the manufactures Bank.n With this LC, manufactures can start procurement of yarn, fabric, accessories etc necessary for particular order execution.

- If the LC delayed from buyers end, it will impact on the delivery date and merchandisers need to follow this up with buyer to get the LC for on time delivery.

- Back to Back L/C: To procure the yarn, fabric and accessories, suppliers need to open another LC for secondary suppliers bank based on the master LC. This secondary suppliers LC is called back to back LC.

UD [Utilization declaration]

- UD-[Utilization declaration] suppliers need to submit master LC, back to back LC, bank certificate, BTMA certificate of yarn, Invoice of the yarn to get the UD from BGMEA/BKMEA. And to get the GSP form A, suppliers need to submit the UD and other necessary documents to EPB.

- This UD is mainly for the yarn procurement to show that the suppliers have procured the yarn for those particular orders.

Remarks:

The Rupashi Knit wear Industries Ltd. has an energetic and motivated marketing & merchandising team. There are five strong merchandising units are working. The particular unit works for particular buyer. They are always in communication with the buyers. The marketing section also looks after the quality & quantity requirement of the buyers.