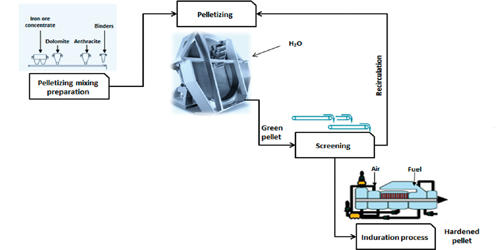

Pellets are manufactured in the pelletizing plant from an iron ore concentrate. Pelletizing is a method of agglomeration, or particle size enlargement, in which material fines are processed into pellets or granules. It is the process of compressing or molding a material into the shape of a pellet. It is used throughout a multitude of industries to process thousands of materials from difficult to handle powders and fines, into easy to handle pellets. A wide range of different materials is pelletized including chemicals, iron ore, animal compound feed, plastics, and more.

Pelletizing of iron ore

The principle behind pelletizing processes is the opposite of grinding technology: it consists of gathering together or clustering fine solid particles in order to form elements of larger dimensions. Iron ore pellets are spheres of typically 6–16 mm (0.24–0.63 in) to be used as raw material for blast furnaces. They typically contain 64–72% Fe and various additional material adjusting the chemical composition and the metallurgic properties of the pellets. The process of pelletizing combines mixing of the raw material, forming the pellet, and a thermal treatment baking the soft raw pellet to hard spheres. The main advantages of granulation are the densification of the material, which enables storage and transportation costs to be cut, providing easier handling of the material and even improving its fluidity. Pelletizing is the most widely used process for the size reduction of many thermoplastic materials, including raw polymers and mixed compounds.

Preparation of raw materials: Additional materials are added to the iron ore (pellet feed) to meet the requirements of the final pellets. This is done by placing the mixture in the pelletizer, which can hold different types of ores and additives, and mixing to adjust the chemical composition and the metallurgic properties of the pellets.

Formation of the raw pellets: The formation of raw iron ore pellets, also known as pelletizing, has the objective of producing pellets in an appropriate band of sizes and with mechanical properties high usefulness during the stresses of transference, transport, and use.

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. The pelletization process is the primary consumer of binders in the iron ore industry. With many benefits and a highly customizable process, pelletizing has become a staple in many industries, with new applications for this valuable process constantly on the rise. The main disadvantage of clays and other binders based on silicate minerals is that they add silica to the finished pellet.