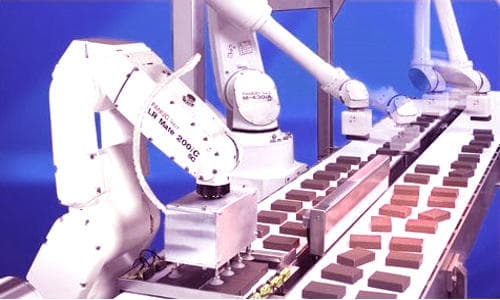

Machine vision (MV) is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. It uses sensors, processing hardware, and software algorithms to automate complex or mundane visual inspection tasks and precisely guide handling equipment during product assembly. Machine vision refers to many technologies, software and hardware products, integrated systems, actions, methods, and expertise. Applications include Positioning, Identification, Verification, Measurement, and Flaw Detection. Businesses use machine vision systems in a variety of ways to improve quality, efficiency, and operations.

“Machine vision refers to many technologies, software and hardware products, integrated systems, actions, methods, and expertise.”

Machine vision as a systems engineering discipline can be considered distinct from computer vision, a form of computer science. This system will work tirelessly performing 100% online inspection, resulting in improved product quality, higher yields, and lower production costs. It attempts to integrate existing technologies in new ways and apply them to solve real-world problems. For any machine vision system to work reliably and generate repeatable results, it is important to understand how these critical components interact.

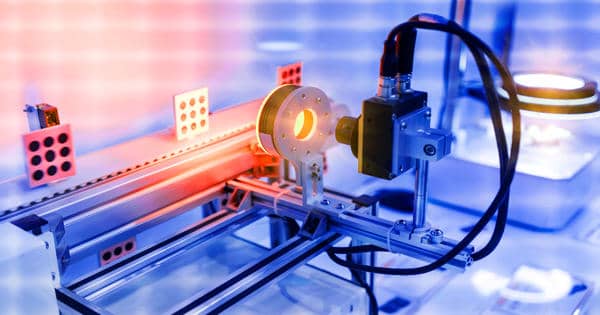

The overall machine vision process includes planning the details of the requirements and project and then creating a solution. This technology has revolutionized manufacturing and industry. During run-time, the process starts with imaging, followed by an automated analysis of the image and extraction of the required information. Today’s industrial cameras and imaging systems allow us to see and record images in ways that the ancient visionaries and early developers of image capturing devices could not have imagined. This field encompasses a large number of technologies, software and hardware products, integrated systems, actions, methods, and expertise. This technology has evolved from discoveries made in optics, chemistry, physics, electronics, television, mechanical design, mathematics, software, artificial intelligence, computers and computer vision, and the internet, just to name a few.

Machine vision is practically the only term used for these functions in industrial automation applications; the term is less universal for these functions in other environments such as security and vehicle guidance. Industrial vision systems demand greater robustness, reliability, and stability compared with an academic/educational vision system and typically cost much less than those used in governmental/military applications.

The term is also used in a broader sense by trade shows and trade groups such as the Automated Imaging Association and the European Machine Vision Association. Machine vision systems rely on digital sensors protected inside industrial cameras with specialized optics to acquire images so that computer hardware and software can process, analyze, and measure various characteristics for decision making. This broader definition also encompasses products and applications most often associated with image processing. The primary uses for machine vision are automatic inspection and industrial robot/process guidance. As technology continues to get more sophisticated, the use cases for machine vision will continue to grow.