Executive Summary

Since independence Bangladesh has come a long way, and the Beximco Group of Companies is honoured to have had a role in the development of its parent nation. The Group has worked with a simple philosophy; identify an important need and then do everything possible to successfully satiate that need, in a manner, which best facilitates the well being of the nation. As a result Beximco has focussed on those industries, which give Bangladesh a competitive advantage in the global market place in many cases creating the industries for the first time in the region.

Presently Beximco Group comprises twenty one companies of which five are listed with the Dhaka Stock Exchange employing over 35,000 personnel and is the largest private sector industrial conglomerate in the nation. . In the course of its growth, it has created industrial and management capabilities that will serve the country for generations to come. It was the first local conglomerate to embrace an international corporate structure which is the foundation of its success. BEXIMCO’s industrial businesses include jute, textiles, basic chemicals, pharmaceuticals, and ceramics.

Introduction:

Internship is the mandatory for all MBA students to fulfill his Master of Business Administration in Marketing because it gives first hand experience of the complexities of practical life. As a result it benefits the students to relate our acquired knowledge with practical job life. The prime objective of the internship program is to work under organizational environment so that, we can tern up ourselves as professionals with practical experience and can get a opportunity to reconcile the theoretical knowledge with real life situation. For this reason internship is an indispensable part of MBA program. I try to prepare this report on the basis of practical knowledge, which I gather from this organization.

Origin of the report:

As a part our MBA program I have to accomplish my Internship from an organization. And in this process I have completed 3 months internee in Beximco Textile limited. Beximco is one of the largest organizations in our country and I have to involve all most all activities related with marketing. This company has four sections and I’m involved in the woven fabric section. I work only in head office of this company. The report mainly concentrates on the processing system of buyers order on woven fabric in the Beximco textile Limited (Head Office).

Objectives of the study:

The study attempted to explore and examine the present market situation of Textile and the Marketing Implications in Textiles Industry specially the objective of the study as follows:

1) To know the present scenario of the market of BexTex Ltd.

2) To identify the marketing objectives of BTL.

3) To analysis the marketing mix strategies of BTL.

4) To learn about the product manufacturing policies of BTL.

5) To know the quality control system of BTL.

6) To know the market controlling policies of BTL.

7) To find out the operational procedure of BTL.

8) To learn about the different challenging segment of BTL.

9) To know about the marketing environment of BTL.

1.1 Methodology of the study:

I have used both primary and secondary data for preparing this report. But most of the data are collected from primary source. I observed various activities of Beximco Textile Limited. My practical experience in Beximco Textile Limited (Head Office) was a great source of information.

(A) Primary source of Data: |

|

(B) Secondary source of Data |

|

1.2 Limitation of the study:

The limitations of the report including the following:

- Lack of time: one of the major limitations of the study was limited time. The nine allocation of the study was inadequate. Because in this short time one inter student had to both attend the office and also do the survey. For the scarcity of time I could not communicate largely with concern persons and authority, which would be very helpful for preparing, the report could be made much more comprehensive.

- Administrative secrecy: Another major problem every private company maintains some secrecy of its sales and Bextex Ltd. Was not expected in this regard. The authority kept much information as secrete.

- Lack of adequate information: there was lack of necessary information what I was needed. That is primary and secondary data.

- The training department has failed to give proper direction.

- Information’s is not updated.

- Lack of knowledge about textile industries.

- Lack of self-knowledge concerning report preparation, was also a limiting factor in preparing a better report.

- The secondary data that have been observed was in a form, which is not helpful for this study.

The Company Profile

2.1 Establishment and History:

Beximco Group is the largest and most diversified business conglomerate in the private sector in Bangladesh. It employs about 25,000 people and its core businesses are Textiles, Jute, Chemicals, Real Estate, Ceramics, Marine Foods, and Trading. Beximco holds 17% of the market capitalization of Dhaka Stock Exchange.

Beximco Textiles is one of the leading and technologically most advanced textile industries in Asia. Our vertically integrated operation is located on 200 acres of private industrial park in Dhaka, Bangladesh.

Padma Textile Mills Ltd, the yarn manufacturing unit produces 36 million pounds of ring spun yarn per year.

Beximco Textiles Ltd. weaves, dyes and finishes 100,000 mts. of fabric per day. It produces Solid and Yarn dyed fabrics like Twill, Canvas, Sateen, Poplin, Dobby, Oxford, Seersucker, Chambray etc. in various compositions like 100% Cotton, T/C (65p/35c), CVC (60c/40p) etc. It also produces stretch fabrics and the garments made out of our stretch fabric can use the Dupont Lycra label. It can insert a maximum of 6 colors in the weft and do various finishes like wrinkle-free, chintz, paper touch, teflon (Dupont), water repellent, dry and wet peach, airo finish etc. It is very strong in cotton wrinkle-free products and can achieve a D.P. rating of 3.5+. Its fabric is Oekotex certified and is produced from high quality ring spun, auto-spliced, electronically cleaned yarn, woven on latest Toyoda air -jet looms from Japan and continuously dyed, finished and pre-shrunk on state -of-the art machines from Monforts, Theis, Goller, Beninger of Europe.

Beximco Knitting Ltd. produces 14 tons per day of a wide range of knit fabrics like Single Jersey, Polo Pique, Lacoste, bubble-knit, waffle knit, popcorn, herringbone, lycra jersey, auto/feeder stripe pique/jersey, engineering stripe etc. Its special items include, semi-jacquard, teflon finish, UV protection finish, core-spun wrinkle-free fabrics etc.

Beximco Denims Ltd. manufactures 18,000 yds. per day of Indigo Denim, bull twills, sulphur black denims, slub denims, stretch denims, dobby denims etc. in weights ranging from 4.5 oz to 13.00oz.

Five apparel manufacturing units, Beximco Apparels Ltd. (1 & 2), IKAL (1&2),

and Beximco Fashions Ltd. produces about 20 million pieces of apparels per year (mostly dress/casual shirts, bottoms, polo shirts etc.)

Freshtex (BD) Limited, a world class washing plant, put up in collaboration with ALT Group of Germany does various washing including sandblasting, whiskering, tie-dye etc.

Apart from manufacturing, we have also focused on innovation and service. Our R&D cell is constantly looking for possible new developments. Our designers are directly linked with Spanish, Italian, and German fashion houses and are in active interaction with key customers in USA and Europe. We visit various trade shows and exhibitions like MAGIC, Premiere Vision, Expofil, Texworld etc. Our enterprise wide software and private satellite connection enables us to link with our customers as well as suppliers.

We are major user of US Pima cotton for high-value fabrics with fine counts like 50/1, 60/2, 80/2, 100/2 etc. We have license agreement with Supima and Cotton USA to use labels on garments.

In the US we are supplying to Phillips Van Heusen (DKNY, Calvin Klein, Kenneth Cole, Arrow, Geoffrey Beene, Izod, Bass, John Henry etc.), JC Penney, The Gap, Perry Ellis, Levi’s (Dockers, Levi’s etc.), Federated etc. In our roster of European buyers we have NEXT, Zara, H&M, C&A, Carrefour, Auchan, BHS, M&S, Hagger, IC Company, Marks & Spencer, Mango etc.

2.2 Company Mission:

Bextex Ltd. is a full service vendor with strong vertically integrated production facilities as well as creative & analytical capabilities which clearly sets us apart from most other South Asian vendors.

2.3 Company Vision:

• Gain market leadership in high value added apparel in USA & Europe.

• Use “Innovation” & “Speed” as prime drivers, rather than cotton & cheap labour .

• Dominate these markets in high quality:

- Men’s, Women’s, Children

- Shirts (Dress & Casual)

- Blouses (formal & casual), Skirts, Jackets

- Jeans & Casual non – denim bottoms

- Knitted tops & bottoms

2.4 Their Commitment to the Environment:

Our company is very committed to preserve a healthy and pollution-free environment. It has a very efficient waste collection and disposal system. In order to reduce air pollution by exhaust of gas from engine-generators, it maintains a costly plant that uses the exhaust gas to generate steam for chilling unit. Above measures not only help keep the water & air free from pollution but also help save cost of water treatment & air conditioning. Your company uses only AZO-free dyes and is dedicated to ensure a healthy and eco-friendly environment.

| BEXTEX Limited | |

Corporate Headquarter

| 17 Dhanmondi R/A, Road No. 2 Dhaka -1205, Bangladesh Phone:8611891-5,8618220-7,9677701-5,7701165 |

Operational Headquarter

| Sarabo, Kashimpur, Gazipur BeximcoIndustrial Park, |

Factory

| Sarabo, Kashimpur, Gazipur |

Date of Incorporation

| 30 May, 1984 |

Commercial Production

| 1990 |

Business Line

| Manufacturing and Marketing of Yarn, Woven, knit and Denim Fabric. |

Listing Status

| Public Listed Company. |

Stock Exchange Listing:

| Dhaka and Chittagong. |

Authorized Capital in BDT:

| 3,000 Million Taka |

Paid Up Capital in BDT:

| 1,882.50 Million Taka |

Number of Shareholders:

| 37,929 |

Number of Woven Loom Installed:

| 293 |

Number of Spindles Loom Installed:

| 119,520 |

Number of Denim Loom Installed:

| 56 |

Number of Circular Knit Loom Installed:

| 30 |

Production Capacity:

| 28 Million Linear Meters |

Number of Employees:

| 5, 18 |

BOARD OF DIRECTOR AND MANAGEMENT TEAM

2.5 Main Buyers of Beximco Group:

2.5 Main Buyers of Beximco Group:

Beximco textiles division offer readymade garments, as its product. The main customers of Beximco textiles are from Europe and America. The main customers are:

JC penny purchasing corporation | |

Springfield | |

Phillip VAN Heusen | |

Calvin Klein | |

H&M | |

C&A | |

Zara | |

Next | |

IZOD | |

St. JohnsBay | |

Arrow | |

J. Ferrar | |

Bershka | |

Kenneth Cole Reaction | |

ESPIRIT | |

CHAPS | |

Levis | |

Tom Tailor | |

DKNY | |

Decree | |

Geoffory Beene |

2.6 Management Structure:

The company is operating through a well defined management structure headed by a chief Executive Officer under whom there are various departmental heads and according to hierarchy, various senior and mid level management staffs. The chief executives officer and departmental heads meet at regular interval

2.6.1 The Board of Director:

The board of director is responsible to the share holders for the strategy development of the company, the management of the company’s assets in a way that maximized performance and the control of the operation of the business.

The board of the directors is responsible for approving company policy and is responsible to share holders for the company’s financial and operational performance. Responsibility for the development and implementation of company policy and strategy, day to day operational issues is delegated by the board to the management of the company.

2.6.2 Board Structure and Procedure:

The membership of the board during the year ended 2007 may 2005 stood at four director, which is higher than the legal minimum requirement of three director. The shareholders appoint the director in annual general meeting and through them exercise their control proprietorship over the company.

The company’s board currently comprise the chairman( Also Managing Director) And other three director of the others three director to are nominated by Bangladesh Export Import Company Ltd ( One of them is also the Chief Executive officer ) and other one is the nominee of Industrial promotion & Development Company of Bangladesh( IPDC). The quorum of the board is at least three directors present in person.

2.7 Functional Department of Beximco Textile Ltd:

Beximco Textile Ltd. is one of the structured organizations of Beximco Group? All the responsibilities of the company are divided to ten different departments. The department looks after total factory operations. It has a number of sections and each section has definite responsibility.

- Production Department

- Marketing and Sales

- Planning, Commercial & Marketing

- Procurement Department

- Computer Department

- Finance and Accounts

- Management Information Department (MIS)

- Administration Department

- Human Resource Development (HRD) Department

- Marketing Research, Development & Sales

2.7.1 Production Department:

The production depart is headed by director operation and has wide range responsibilities. This department looks after total factory operations. It has a number of sections, namely production planning, administration, stores and go down, power and fuel, maintained and delivery sections. Each section has definite responsibility.

2.7.2 Marketing & Sales:

The main duty for the marketing department is to convince the buyer. The search for the buyers who are looking for RMGs from Bangladeshi Garments coming from deferent part of the world. As the buyers are highly concern in fabrics they test the sample and marketing department deals this sample- testing price and time of shipment.

2.7.3 Planning, Commercial and Marketing:

As the company’s product is very sensitive that without period specification no buyer will take any fabric until and unless the construction matches exactly with their requirement. So getting the contract of order from marketing department they prepare and order Execution schedule specifying the amount and construction of the fabric for production department considering lead time they sent the schedule at least two month prior to the production. And finally they sent a production order to the production department confirming the contract.

2.7.4 Procurement Department:

The principal function of the procurement depart is to source the materials both local and foreign as required and requested by the user department. In the case of imported materials the responsibility of the procurement department included the establishment of LC in favor of foreign vendors

2.7.5 Finance & Accounts:

The department comprises two sections- Finance & accounts. Finance is mainly responsible for source and uses of funds, and inventory management. In this connection they have to prepare a number of reports necessary to express the inventory position and have to go to the factory at least ounces in a month to inspect the physical position of the inventory and to investigate weather there are anomalies in records and physical existence. Another task of the department is to deal with the long-term lone in paying the installment and interest.

The final result of all the works in the accounts department are financial statement balance sheet. Profit & lose accounts, Cash Flow statement etc. to produce such report there deal a lot of works. The department is required to do the same for monthly than quarterly and finally for the year. All the payment is through the accounts department. It may be for raw materials purses of salary of the employees any other expanses. Similarly all the Inflows are through the accounts.

2.7.7 Software Use in Beximco:

I saw in production sector complicated production machineries operated by special designed software. In the liaison/head office of marketing is using very little general software suppose for payments of bills and other document preparation they are using Ms Access. The internal communication (office to office) is done through internet. Auto CAD, CAD CAM, Photoshop is widely used by the designers. Corporate office widely uses tally and Ms Access to maintain their accounts and financial dealings. For Email communication, all people are using EUDORA mail client program.

2.7.8 Beximco exports

Beximico exports their goods in the in France, Belgium, Germany, Holland, Denmark, Norway, Italy, UK, Spain, Finland, Switzerland, USA and Canada.

3.1 Specific Internship Position &Duties:

Mainly I have done my internship in marketing and sales department in Beximco textile industries Ltd. I work under the supervision of manager of marketing and my main task was receiving various types of data information and making database. During my internship period my daily task was taking data from the buying house and sends it to the factory to produce the fabric through the E-mail or send it to the factory physically.

As most of the time I have to manipulate with various raw data so that time I was also able to help accounting division by providing various necessary data. In preparing database I have used Microsoft Excel and Microsoft Word. I also took access to the Internet and office Internet for providing and taking necessary information.

In the course of my internship I also did some task in the marketing division. Some of the task during my internship is mention bellow:

- To check daily E-mail of the different Buying house. I try to communicate with buying house and identify our order, which are beneficiaries for this organization. Most of the times we communicate with them on E-mail and show them our fabric sample, swatch, cad and garments. Then I prepare the documents, which is necessary for our organization.

- To compare their order in the percentage base. For this reason I collect last month data to compare increasing or decreasing rate in the percentage base.

- To summaries there order at the end of the month. At the end of the month I collect data and try to compare data with previous month. Then I inform it to the mid-level authority.

- To receiving organizations or customer phone call for providing required information. Some time buyer call me and try to get information about our customer and try to know about our fabric processing procedure then I provide them book or brochure etc. Our peon physically communicates with them.

- To sales order processing. I go to the delivery store and request them for delivering my customer fabric.

- To communicate with the yearn factory to get my yearn which is necessary yearn for my fabric as the buyer requirements. In the mean time I visit the factory and I saw how they produce the yearn. I saw there firstly they collect the cotton from Thailand, India, Pakistan and then they processing it in their comber matching. And finally this matching produce the yearn.

- To prepare print out, photocopy documents, which is very important for this organization.

- I communicated with the design studio. At first buyer came in the studio for checking our design. I try to show my design, which is previously produced in this factory.

- I collected cheek from the accounts at the end of the month. And give it to my concern party.

- I communicated with the quality control department for prepare my fabric. Fabric quality is good or bad I try to identify it by using their quality control department. To complete this task I visit the factory and I saw how they produced the fabric.

- I went to the design cell for collecting the dispo number. It is the color number, which is related with the fabric. Every day we need to dispo number for preparing the fabric. Most of the time I collect it and give it to the planning department for preparing the costing function.

- I went to the yarn store for collecting the necessary yarn, which is needed for fabric. For this I prepare the document and give it to the yarn store manager.

3.2 Major Learning Points:

During the time of internship program in the Beximco Textile Limited, I assemble many learning things, which inspire me. The learning things are pointed in the following-

- In the time of my internship period I learnt how to make a document for the buyer order I try to summarize how many order collect in a month and how many fabric sale in a month.

- Before joining as an internee in the Beximco Textile Limited I do not understand properly about the fabric making process. After three month of working period I have a clear conception about the fabric making process.

- problems arise in the marketing section in Beximco Textile Limited then I try to communicate with the concern party for the problem. So my communication skill must be increase for this.

- Before working in the Beximco Textile Limited I have no job experience and have no concept how an organization follows time management. After working in the Beximco Textile Limited I have clear conception about time management practices of an organization.

- Adoption in any situation is not so easy. Every time I try to communicate with the higher authority and lots of employee who working here but they are not Bangladeshi. Lots of foreign people work in the Beximco. I try to communicate with them for my necessary information. For this reason I things my adaptation power must be increase.

- Before working in the Beximco Textile Limited I was very week in speak in English but After working in the Beximco Textile Limited I gather some experience to communication with in English.

- Before working in the beximco I have no idea about yarn making process but now I have clear idea about the making process of yarn.

- Previously I have no idea about the graphics design but at present I can make the design for fabric.

- Before working in the Beximco I have no idea about the CAD, swatch, sample, and count of the yarn but now it is very familiar word for me. I know very well about the CAD, sample, swatch and count of the yarn and those making process.

- In the time of my internship I learnt about the comber machine which is very popular for producing the yarn and how it done the work.

- In the time of my internship I learnt about how a person can develop his career and maintain his subordinate.

- I learnt about the corporate culture, which is strictly maintained by the organization.

Theoretical Aspects

3. 3 Customer- Centered Marketing strategy

To succeed in today’s competitive market place, companies or banks need to be customer centered. They must win customers form competitors, then keep and grow them by delivering greater value, but before it satisfy customer, a company or bank must first understand their needs and wants. Thus, sound marketing requires a careful customer analysis. Companies or banks know that they can not profitably several all customers in a giving market-at least not all customers in the same way. There are too many different kinds of customers with too many different kinds of needs. Moreover, most companies or banks are in position to serve some segments better than others are. Thus, each company must divide up the total market, choose the best segments and design strategies for profitably serving chosen segments. This process involves three steps:

Market segmentation

Target marketing

Market positioning.

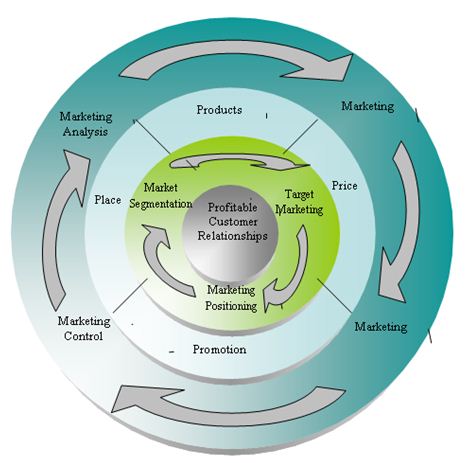

Figure-: Customer Centered Marketing Strategy & Marketing Mix

Market segmentation:

Dividing a market into distinct groups of buyers who have distinct needs, characteristics, or behavior and who might require separate services or marketing programs is called market segmentation. A market segment consists of customers who respond in a similar way to given set or marketing efforts.

Target Marketing:

The process of evaluating each market segments attractiveness and selecting one or more segments to enter. A company should target segments in which it can profitability generate the greatest customer value and sustain it over time.

Market positioning:

Arranging for product or service to occupy a clear, distinctive, and desirable place relative to competing products or service in the minds of target customer. Thus marketers plan positions that distinguish their products or services form or competing brands and give them the greatest strategic advantage in their target markets.

3. 4 Capturing value form Customers

The first four steps in the marketing process involve building customer relationship by creating and delivering superior customer value. The final step involves capturing value in return, in the form of current and future sales, market share, and profits. By creating superior customer value, the firm creates highly satisfied customers who stay loyal and bye more. This, in turn, means greater long-run returns for firm. Here, we discuss the outcomes of creating customer value: customer loyalty and retention, share of customer, and customer equity.

Creating Customer loyalty and Retention

Good customer relationship management creates customer delight. In turn, delighted customers remain loyal and talk favorably to others about the bank and its services. Studies show big differences in the loyalty of customers who are less satisfied, somewhat satisfied, and completely satisfied. Even a slight drop from complete satisfaction can create an enormous drop in loyalty.

Companies are realizing that losing a customer means losing more than a single sale. It means losing the entire stream of purchase that the customer would make over a lifetime of patronage. For example- here is a dramatic illustration of Customer Lifetime value.

Growing Share of Customer

Beyond simply retaining good capture customer lifetime value, good customer relationship management can help marketers to increase their share of customer- The share they get of the customers purchasing in their service categories. Many marketers are now spending less time figuring out how to increase share of market and more time trying to grow share the customer.

Customer Equity

- The combined customer lifetime values of all current and potential customers.

- Measures a firm’s performance, but in a manner that looks to the future.

- Choosing the “best” customers is key.

3.5 Customer Needs, Behaviors, and Values Clarified

- Banks achieve better prospect and customer management by combining profitability, behavioral segmentation, and analysis

- Banks deliver information to customer touch points (e.g., branches or call centers) to influence customer activity and workflow management

- Stage Two banks manage and influence the workflow of their branches and call centers, and generate more effective customer acquisition and management activities

3. 6 Building the Right Relationships with the Right Customer

Companies should manage customer equity carefully. They should view customers as assets that need to be managed and maximized. Nevertheless, not all customers, not even all loyal customers are good investments. Surprisingly, some loyal customers can be unprofitable, and some disloyal customer can be profitable. Which customers should the company or bank acquire and retain. The company can classify customers according to their potential profitability and manage its relationships with them accordingly customer relationship groups. This group classifies customer into one of four relationship groups, according to their profitability and projected loyalty. Each group requires a different relationship management strategy. Which are discussed follows very briefly:

| Butterflies Good fit between companies or banks offerings and customer’s need; high profit potential. | True Friends Good fit between companies or banks offerings and customer’s need; highest profit potential. |

| Strangers Little fit between companies or banks offerings and customer’s need; lowest profit potential. | Barnacles Limited fit between companies or banks offerings and customer’s need; low profit potential. |

High

Profitability

Low

Profitability

Figure-: Different relationship management strategy

Butterflies: Are profitable but not loyal. Good fit between companies or banks offerings and customer’s needs. However like real butterflies, we can enjoy for only a short while and there gone.

True Friends: Are both profitable and loyal. There is strong fit between their needs and the companies or banks offerings. The firm or bank wants to make continuous relationship investments to delight these customers and nature, retain and grow them. It wants to turn true friends into “true believes” who come back regularly and tell others about their good experiences with the bank or company.

Strangers: It shows low profitability and little projected loyalty. There is little fit between the companies or banks offerings and their needs. The relationship management strategy for these customers is simple.

Barnacles: Are highly loyal but not very profitable. There is a limited fit between companies or banks offerings. For example- a Uttara bank customer who is regularly but do not generate enough returns to cover the costs of maintaining their accounts. Like barnacles on the hull of a ship they create drag. Barnacles are perhaps the most problematic customers. The bank might be able to improve their profitability by selling them more, raising their fees, or reducing service to them. However, if they cannot be made profitable, they should be “fired”.

The point here is an important one: That is different types of customers require different relationship management strategies. The goal is to build the right relationships with the right customers.

Findings and Analysis

4.1 Present Scenario of the Textile Market in Bangladesh:

Bangladesh is the best place in the region for textile and garments industry due to cheap labor and favorable trade status with the EU. There is a huge yarn and fabric demand and supply gap in RMG industries, which is presently met by import. Presently is about 85%-90% of the demand is met by import from countries like China, India, Hong Kong, Singapore, Thailand, Korea, Indonesia, Taiwan etc. fabric requirement is increasing at 20% per annum. In order to stimulate rapid economic growth of the country Bangladesh Government encourage foreign investment and establish six individual export processing zone (EPZ). During the July-March 2006-07 periods, overall exports of the country reached US $9036.4 million. Represents a surge of over 20%, especially on the back of footwear and garments. Knitwear industry failed to achieve target exports of $3485.2 million and earned around $3335.2 million. Fazlul Haq, President, Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), explained, “The failure is due to the adverse effect of labor unrest in the garment sector in May 2006.”

(Source: www.fiber2fashion.com).

Currently the number of membership of BTMA is 935 under:

Weaving (Fabric Manufacturer) = 458

Dyeing-Printing-Finishing (Textile Product Processor) = 159

Over 2.50 billion EURO has been invested in these mills and about 3.50 million people are currently employed.

Labor cost incurred in the industry is the lowest compared to its competitors

Table no-1: Labor cost & its competitors

| Country | Labor cost per hour | Country | Labor cost per hour |

| Thailand | $ 1.00/Hour | Indonesia | $ 0.40/Hour |

| India | $ 0.60/Hour | Pakistan | $ 0.40/Hour |

| Sri Lanka | $ 0.45/Hour | China | $ 0.35/Hour |

| Vietnam | $ 0.40/Hour | Bangladesh | $ 0.25/Hour |

(Source: BKMEA websites)

Energy cost in Bangladesh in lower compared to India and Pakistan

| Country | Cost/KwH |

| India | $ 0.095/KwH |

| Pakistan | $ 0.08/KwH |

| Bangladesh | $ 0.07/KwH |

(Source: BKMEA websites)

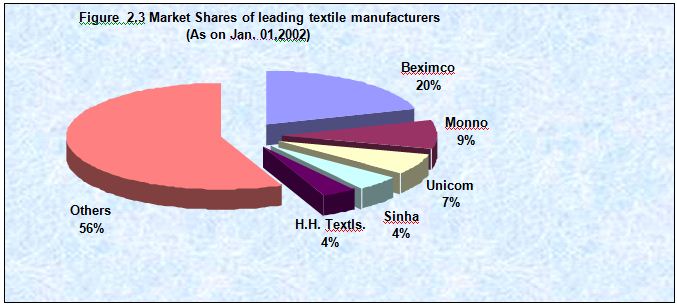

Competitive Position in the local industry :

BEXTEX Limited by nature operates in the weaving and finishing segment of the complex structure of the Textile & Clothing industry of Bangladesh. The local textiles producers did never exert threats to the company. Rather it is the textile giants in Chaina, India, Indonesia, Pakistan are the major competitors of BTL as the company’s perception, because most of them operate in the same markets as like as BEXTEX Limited.

In the local industry BexTex Ltd. is currently grabbing a big volume in terms of the share in the export-oriented RMG market.

4.2 The Objectives of the Company is given below:

Beximco Textile Ltd (BTL) runs their business with secure growth in terms of profit for re-investment to sustain market share and to diversity into new areas. It also contributes to the yarn industries that produce thread garments manufacturing and other subsidiary unit some goals of the company’s are –

- Provide highest standard products and secure customer satisfaction.

- Secure strongest competitive production through creative product and operational excellence.

- To increase to company’s familiarity.

- To diversify the business.

- To ensure growth both in terms of sales and profitability.

- To maintain growth and market share.

- To create more employment opportunity to the nation.

- To provide the consumers better quality products.

4.3 Marketing Mix Strategies of BTL:

In deciding on tile marketing program, a company must decide how much to adapt its marketing mix i.e. 4p’s (product, price, promotion and place) to local conditions, at the two ends of the spectrum are standardized and adapted marketing mixes, with many step in between. At the product level, firms can pursue a strategy or striate extension, product adaptation, or product invention, at the promotional level, firm may choose communication, adaptation or dual adaptation. At the price level firms may encounter price escalation and grey market and it may be very difficult to set standard, prices. At tile distribution level firm need to take a whole- channel view at the challenge of distributing its product to the final users. In creating all elements of the marketing mix firm must be aware of the cultural, social, political, Environmental, technological and legal limitations they face in other countries.

Now here we will examine potential adaptations that Beximco Textile Ltd. Might make to their product, promotion, price, and distribution as they enter foreign market.

4.3.1 Product:

Weave fabric:

Solid dyed – poplin, twills, dobies, oxfords, secrsuckers, canvas, rib stops in 100% combed cotton- CVC and CVS/TC stretch satten.

Yarn Dyed– Ginghams, strips, Fat-a-fills / End-on-ends, chambrays, Seersuckers, Pint point, Oxford, Dobbies, plaids in 100% combed cotton CVC and CVS/TC-stretch- Sateen.

Dobby designs– Herringbones, Bedford Cards/Coteles, Waffles and various structures in 100% combed cotton. CVC and CVS/TC.

4.3.2 Promotion:

Promotion, the marketing tools, standards for the various activities the company under take to communicate Its product’s benefits and to pursued taget customer by it. The firm has a plan to expand its market and according to that plan it has stands to increase its promotional function.

Action to be taken:

In the overseas market the company promotes its product by-

Provide Sample, Brochure, Collection, Attending international fair, CD supply, Participation in auction over internet, Fashion Show, E-mail, Fax, Various Journal, Cortex, Magazine, etc.

4.3.3 Price:

The amount of the company charged for a product or service, or the sum of the value that customer exchange for the benefits of having or using the product or service called price.

Determining Demand:

This organization determines demand by analyzing its previous sales volume. The company market estimates are helpful in establishing the relationship between its product price and the quality.

Pricing Policy:

As the company has an objective to stay in the market along possible with this business, its has adopted the market based price policy.

As the shops are either franchise or agent of the mother business, they try to follow the pricing strategy formulated by them. In such case some shop like Reebok, Woodland set prices of their items as their franchiser wants. The other surveyed shops set price by adding their desired profit margin to the purchase price.

4.3.4 Distribution:

Our objective is this study was to know about the distribution toward the existing marketing system. To fulfill objective some selected issue that are influencing the existing marketing system have been discussed.

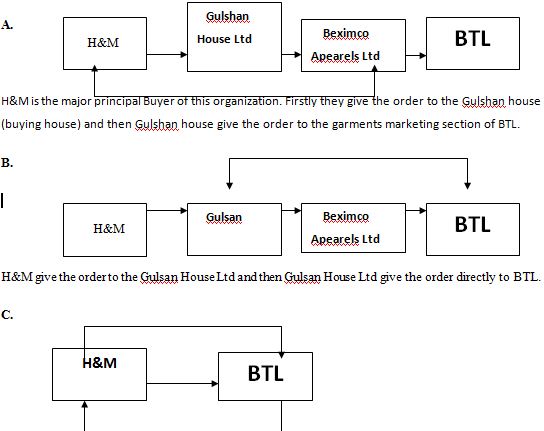

Distribution Channel:

The channel structure used to transfer product and service foreman organization to its market. Generally the company is issued direct channel.

H&M give the order directly to BTL.

At first the companies try to fulfill the buyer demand. If 5% lower or over production from the order then it will be acceptable by the buyer in according to contract schedule. On the other hand when tile quality of tile product is not as good as there requirement or expectation then they canceled it.

Then the company tries to sell this reject product to buyer by corresponding with each other. Otherwise the company sells this reject product in the local market. The local market distribution channel is as follows.Another distribution channel maintained by the BTL for our local market. Firstly they produce the fabric for our local market then they give it in their sale center yellow shop in our country then customer can purchase it from the sell center.

Transportation:

BTL maintain its own transportation system for delivering product to intermediaries as well as the company contract with cargo-Bungle Transport Agency for delivering product.

4.4 Product Manufacturing Policies of BTL:

Bextex Ltd is the most modern composite textile in the Asia- Pacific region. The Bextex Ltd has a capacity of 288 high speed air-Jet looms in its weaving section and a high tech dyeing and finishing section with capacity of 1,00,000 meters of finished fabric per day. A good number of technician and engineers had been abroad for getting to adjust with this machine.

But the company can able to utilize 80% of their production capacity.

BTL produce high quality 100% cotton fabrics, which help to maintain of modern civilized life. The company spends large efforts toward marketing of textile product by trying to provide high quality with reasonable price.

Source of raw materials:

Availability of raw materials is important for product and its quality as well as further production. Cost of product also depends on the availability of raw materials. The basic raw materials of textile products are:

- Yarn

- Dyes & Chemical

Yarn: The Company collects their yarn 90% to 95% from Padma Ltd. And 5% to 10% from overseas such as India & Pakistan.

Dyes & Chemical: The Company collects their dyes and chemical 90% are imported from India, China, Germanys and Europe and 10% are local insuring quality and consistency in fabric shading.

The following table shows the raw material Consume in different year:

| Year | Material consumer |

| 1998 | 1,459,899,333 |

| 1999 | 1,603,592,994 |

| 2000 | 1,859,780,935 |

| 2001 | 1,827,364,739 |

Source: Annual report

Positioning is the act of design companies offering and image so that they occupy a meaningful and distinct competitive position in target customer mind. Comparing with the competitive product a company might position its product on the basis of one or few difference such as importance, distinctiveness superiority, communicability, affordability, profitability and so on.

BTL has positioned its entire textile product at the high quality and reasonable price, with respect to other company’s textiles product in tile market.

Testing activities:

Table No-2: Beximco Fabric Testing Standers, Process and Guidelines

| Test Name | Standard Reference | Test Reference | Performance Standard |

| Washing Stability | BS 4923 | 2A Tumble Dry | -3% Warp and Weft |

| Tensile Strength | BS 2576:1986 | 18 kg | |

| Seam Slippage | BS 3320:1986 | SO 6mm | 8.0 kg |

| Abrasion Resistance* | BS 5690 | Break Down | 20000 revs |

| Piling resistance** | BS 5811:1986 | 36000 revs After Wash | 4 |

| Tear strength*** | ASTMD 142483 | 700g | |

| Wash Fastness | BS 1006 | CO6 C2S | 4S, 4C |

| Water fastness | BS 1006 | E01 | 4S, 4C |

| Dry Rub Fastness | BS 1006 | X12 | 4S |

| Wet Rub Fastness | BS 1006 | X12 | 3S |

* Abrasion test will only be carried out on fabrics for using in trousers or heavy uses finishing.

** Pilling test will only be carried out on fabrics, which contain synthetic fibers in staple form.

*** Test strength will only be carried out on lightweight, 100% cotton fabrics.

In addition to the above tests all fabrics will be tested for the following

Thread per Inch (Warp and Weft)

Fabric’s weight (g/m)

Fabrics Width (Overall and useable)

Monitor group of quality control:

(i) BSTI

(ii) The company has developed product wise quality control specification.

(iii) Customers then self’s also do specify minimum requirements of fabrics.

Checking Activities:

- On-line quality control

- Right from yarn dyed through weaving up to finished fabric

- Off- line testing to maintain the minimum requirement at every stage of processing line to achieve right finished product.

- On-going scheme we do optimum the new product or process introduce into the production line.

Packaging:

BTL are using high quality Polly for packing. Its depend on size of the products. The cost of packing is generally 10% of production cost. Packing materials consumption (opening stock purchase – closing stock). The following table the packing materials consumed in few years

The company is producing usually the following major product-

4.5 Manufacturing process for Textile Goods:

There are two types of manufacturing process for textile products:

- Manufacturing process for yard dyed

- Manufacturing process for solid dyed

4.5.2 Spinning:

The main materials used in the spinning sub-sector are raw cotton and synthetic fibers such as viscose and polyester staple fibers. In this process natural and synthetic fibers are cleaned and twisted into yarn. The row materials are move through the blow room where all impurities are removed from natural fibers only and those are rolled into laps. The laps then go through a carding machine, wee they are cleaned further and formed into silvers, thick and loosely spun yarn. In order to produce combat yarn, the fibers need to be undergoing further processing in the comber machine, were the sort stands are removed, and the remained processed into silver. The silver then fed to the draw frame, and speed removing frame where they are twisted to and drafting take place and yarn is produced. The yarn is then spun around a bobbing or cone, using autoscores or cone winding/reeling machines, packed and marked.

4.5.3 Weaving and Knitting:

|

|

Prior to weaving the yarn is wrapped around beams and dipped in a size, an adhesive, which when dries gives the yarn a rigid and uniform structure. This yearn is then filled into the looms and called yard. A tread of yarn, called the waft, passed between altering ward yarn with the aid of a shuttle, air jet or rapiers.

Knitting is also used to make gray. Instead of looms, circular knitting machine are also used for knitting. Knit fabrics are much softer and more flexible than the produced on looms, and is commonly used for producing article of casual wars such as T-shirts and under garments.

4.5.4 Dying, Printing, Finishing:

At this stage the gray goes for dying, printing and finishing. After the gray is inspected, it goes through a process called the batch method when it undergoes scoring, bleaching and dying. Scouring is the treatment of gray in chemical solution in order to remove the size, natural fats, waxes, proteins and other impurities, and to make the fabric hydrophilicTe batch processing is next. It is essential in giving the cloth a clean white color. It is done using two different methods. One is bleaching with dilute hydro chloride solution at room temperature or by using hydrogen per-oxide solution at elevated temperatures (80 to 90 degree Celsius). The later method is more expensive and usually results better and longer lasting whiteness.

The scoured cloth is then dyed and then printed on. Printing is done using perforated rollers that allow certain chemicals and colors to diffuse through the holes. After that the printing has been completed and finally the fabric is washed again.

4.6 Market Controlling Policies of BIT:

Control and analysis of marketing costs complement each other. Control being with the assignment of marketing expanse to various costing group such as territories, customers and products. Control and analysis are enhanced by

(1) Predetermine cost allowed for marketing effort and

(2) Establishing functional costing rate base as standards and budgets design to aid in achieving objectives.

Marketing Department of BTL. Analysis of marketing cost control and profitability, which are presented under the following topics-

(1) Comprising of manufacturing and marketing cost.

(2) Marketing cost control.

(3) Control of functional activity by the flexible budget and standards

(4) Marketing profitability analysis.

(5) The contribution margin approach.

(6) Marketing cost and profitability analysis problem.

Marketing Department of BTL are control and compared actual with budget under the following cost-

- Selling

- Warehousing

- Packing and shipping

- Promotional

- Credit and collection

- General accounting (for marketing)

When the expanses variance is adverse then corrective action and analysis the company tries to find out why is to done. In many time the company cannot able to export their product, which was expectation then the company take proper step to achieve the target as per example the design teams along with business department staff were already in USA in September 2001 presenting their collection. They were meeting all their existing customers while targeting other big names, which are still not on their customer list. Some of there are Wal-Mart in Mexico, USA and Europe, Federated store of USE, Hudson Bay of Canada. For this reason after September I’ll 2001, hit the economies of the world the company going on with successfully.

4.7 Operational Procedure of Beximco Textile Ltd:

The main task of Beximco textiles is producing various types of fabrics. Generally according to the buyers demand the firm produces these fabrics. Like other organization Beximco textiles also have various departments these are: – administration, accounts, marketing, production and quality control. For Beximco Textile budgeting, financing and administration work is directly supervised and controlled by its corporate office. Beximco textiles management of raw material, production operation management, production, quality assurance, storing finished goods, and a bit accounts’ maintenance is done by the production department. Liaison office works as head office of the Beximco textiles Ltd.

In this branch odder collection, production time and customer desired quality executing, document processing, legal complicacy handlings, dealing with LC s’ and payments and accountants maintaining, shipment, network maintaining with foreign and national buyers is done. In textile most of the order comes from firm’s reputation, firma managements’ network and liaison and few comes from the new local buyers. Beximco RMG direct place there in the production plant to the production DGM.

The main function of the organization may be divided into two parts as:

1. Export 2. Import.

The phases/ Functions in export procedure include:

a. Manufacturing readymade garments and fabric

b. Ex-out the garments

c. Shipment the garments

d. Preparing documents

e. Receive foreign Currency.

Import/ Procurement of raw materials follow the under mentioned steps:

Order placing

Getting/Receiving Performa Invoices

Opening Back to Back L/C

Receiving raw materials

The finance department where I have worked performs to manage the inflow of the company. Inflow management includes the following:

a. Opening back-to-back L/C

b. Local bill discounting;

c. Arrange packing credit

d. Export bill purchase.

e. Receiving payment from maturity.

f. Opening inland L/C.

4.8 Different Challenging Segments in BTL are:

4.8.1 Beximco Denim:

Beximco denim Ltd is a high quality composite denim fabric plant with dyeing, weaving and finishing facilities. It’s also including a modern government washing and dyeing plant to enable the fully integrated production of denim appeals.

Indigo dyes and other chemical are all imported from Germany to ensure tent shades and washing result.

The mills produce in excess of 18000 yards of denim fabrics per day ranging from 41/4 oz. chambray and lightweight shirting denims to heavy bottom weight denims (6 oz.to15 oz). Fabrics are produced using open end /open end, and ring/ring yarns to produce different style. In addition to standard indigo denims, black, colored warp dyed, oven dyed and bull denim are produced. Other fashion denims can be made to suit customer requirements.

4.8.2 Beximco Knitting:

Beximco Knitting Ltd. Is quipped with circular knitting, stare-of the-art computerized kitchen dyeing, and finishing. It produces fine quality cotton and blended knit fabrics in a variety of styles. Jerseys, ribs, piques and other single knits textures care all available. Current production in tubular and open wide exceeds 14 ton per day. Fabric weight range from 130gsm to 260gsm in styles, which include Jersey, piques needle out textures, ottomans mock thermals, popcorns and fabrics with Lycra.

The Beximco Textile industries park is operational 350 days a year-the company has gone to vast length to ensure its smooth running by investing in its own in-house power supply, infrastructure and in-house telecommunication link to the rest of the world.

4.9 Marketing Environment:

Marketing environment of Beximco textiles are the actors and forces outside marketing that affect marketing manager’s ability to build and maintain successful relationships with targeted customers. Marketing environment is divided into two parts microenvironment and macro environment of the company.

4.9.1 Micro Environment

Marketing micro environment contains suppliers, marketing intermediary’s customers, competitors and public. In the case of Beximco textiles the component “Company” itself almost works well with its departments.

Beximco’s suppliers of raw materials policy and cost of raw materials or inflation directly effect the macro environment of Beximco. Customers of Beximco are mostly our RMG producers. So quality ensuring is a big concern here. In the case of marketing intermediaries; company fame, managers’ strong liaison/ network with business buyers are the main strategy of Biswas to sell products. Government policies (favorable) are the main publics here. C Beximco competitors’ of Beximco textile are local producers of Bangladesh. Name of some close competitors of Beximco textile is given billow.

4.9.2 Macro Environment

Macro environments major forces of Beximco’s are discussed bellow.

Demographic factor– South Asian region is suitable for textile industry. Big working population and raw materials outsourcing facility, supports the industrial growth of Bangladesh.

Economic factor- Low production cost, energy availability, workers availability and suitable government policy is the economic factor for Beximco.

Technological factor-China machineries are available and cost efficient for Beximco.

Political factors– Unstable political situation and various types of strikes plays negative roll on Beximco.

Natural and cultural factors- Natural and cultural factors doesn’t play significant role in the macro environment of Beximco.

Analysis:

Service delivery Process:

Table-18 | ||

Percentage | Person | |

Lengthy | 65% | 13 |

Comfortable | 35% | 7 |

Total | 100% | 20 |

Source: Questionnaire Survey

The survey showes that service delivery process is lengthy, so that the customers feel uncomfortable to take this service. Low range of people goes for comfortable, which is alarming for any service organization.

Skill of service provider:

Table-19 | ||

Percentage | Person | |

Yes | 75% | 15 |

No | 25% | 5 |

Total | 100% | 20 |

Source: Questionnaire Survey

Graph: 09(Source: Table-19)

Out of 20 people 15 people said the employees are skilled. Only 5 people said they ere not skilled enough.

4.3.8 The office layout is identifiable:

Table-21 | ||

Percentage | People | |

Yes | 20% | 4 |

No | 80% | 16 |

Total | 100% | 20 |

Source: Questionnaire Survey

Out of 20 people 16 people disagree with the office layout is identifiable and other are agree with it.

4.3.10 The bank’s image:

Table-23 | ||

Percentage | People | |

Yes | 50% | 10 |

No | 50% | 10 |

Total | 100% | 20 |

Source: Questionnaire Survey

The banks todays are operating IT-based operation and their marketing strategies are highly slandered. So that the service takers of UCBL do not get that much encouragement by their colleges, peers, friends etc. so that 50% of my respondent goes for yes and other 50% answer no to this question.

Evaluation of General Banking Services of Uttara Bank Limited

I evaluate the General Banking Services of Uttara Bank Limited based on my customer’s survey through questionnaire. I survey fifteen customers to measure the General Banking Services of Uttara Bank Limited.

{The Questionnaire is used to evaluate General Banking Services of UBL. This question was aimed at finding out the General Banking services provided by Uttara Bank Limited at present. This identification will help in developing the subsequent part of the research.}

5.0 Maximum numbers of people carry Savings Accounts

Uttara Bank Limited is the largest and oldest private bank in Bangladesh. They have huge number of accounts holders under various accounts.

Table: Percentage of account

Account Name | Percentage of accounts | Number of Customer |

Savings A/C | 47% | 7 |

Current A/C | 27% | 4 |

FDR A/C | 13% | 2 |

STD A/C | 7% | 1 |

CC A/C | 7% | 1 |

The above graphical presentation shows that 47 percent customers are maintaining Savings Account in Uttara Bank where 27, 7, 7 and 13 percent people have respectively maintains Current, Cash Credit, STD and FDR account.

5.1 Moderate customer satisfaction level

Table: Customer Satisfaction Level

| Particulars | Percentage | Number of the Customers |

| Delight | 7% | 1 |

| Satisfied | 27% | 4 |

| Moderate | 53% | 8 |

| Dissatisfied | 13% | 2 |

The above graphical presentation shows that 53 percent customers have moderate satisfaction level on Uttara Bank Limited. Some customers are 27 percent satisfied and 7 percent delighted to it. But they have13 percent dissatisfied level.

5.2 Account holders are reliable on Uttara Bank Limited

Uttara Bank Limited serves people through various deposits accounts since 1983. They can able to gain customers reliability on them very quickly.

Table: Reliable

| Particulars | percentage | Number of the Customers |

| Reliable | 80% | 12 |

| Non reliable | 20% | 3 |

The above graphical presentation shows that 80 percent customers are reliable on Uttara Bank Limited. Some Client also has 20 percent non reliable.

5.3 Competitive interest rate provided for deposit accounts

Uttara Bank Limited provides competitive interest rate on deposit accounts.

Table: Interest provided on deposit account by Uttara Bank Limited

| Particulars | Percentage | Number of the Customers |

| Attractive | 7% | 1 |

| Competitive | 47% | 7 |

| Good | 27% | 4 |

| fair | 20% | 3 |

The above graphical presentation shows that a 47 percent customer says Uttara Bank Limited provides competitive interest for deposit accounts to accounts holder. 7 percent attractive and 27 percent good and 20 percent fair.

5.4 Average quality of General Banking service

Customers are average satisfied on the performance of General Banking service.

Table: Quality of General Baking Service

| Particulars | percentage | Number of the Customers |

| Standard | 7% | 1 |

| Average | 53% | 8 |

| Good | 20% | 3 |

| Fair | 20% | 3 |

The above graphical presentation shows that 53 percent customers are average satisfied on General Banking service where 7 percent standard and 20 percent good and 20 percent fair.

4.10 SWOT Analysis:

The SWOT analysis having identified the company’s internal strength and weakness as well as external opportunities and threats. We need to conceder by previous marketing and other related analysis an overall picture has revealed of BTL. It an develop new function business of corporate strategies to accomplice this changes. A SWOT analysis shown in the bellow:

Strength is the power of the company by using it a company may achieve the competitive advantage “Bextex Ltd. Is a well reputed company in the textile industries of the country. It is enormous assets, vast market; leading market position has created an image and position in the textile industries.

Here the existing strength of the company is mentioned as bellow:

Huge capital involvement.

A large amount of assets.

A well-known reputed brand name.

Management competence. Sound marketing skills.

Good material management system.

Availability of efficient and qualified human resources world latest.

Appropriate organizational style.Good financial management.

It has in-house power generation capacity is 12 megawatts.

Road leading to the complex has been built by and are maintained by Beximco.

Tube wells ensure an abundant flow of water.

On-site employee housing provides comfort and easy access to work, and promotes better work performance.

Supervisors and foreign technician live on-site to provide 24 hour coverage.

Dependent on 100% imported raw materials and technology

Difficulties to cope with always upgraded new technology

Administrative cost is comparatively higher

Higher dependency of borrowed capital

- Very higher quality product which have a good demand in both national and international Market

- Market for a large portion of product is insured with in the other sister company of Beximco Group.

- After withdrew of the quota system of garments product from early 2006 demand of the yearn will be higher

- After full integration of total BEXIMCO Textile Division the administrative cost might be lower

- There is a good opportunity for marketing more production in future

- Very competitive national and international market

- Many new companies are coming in front with new port and new technology

- Dependency of foreign countries so far raw materials

- Many neighboring companies are in more advance situation

- National and international yearn market is always Fluctuating.

5.1 Conclusion:

In the basis of finding and analysis, this paper is examined and described how we can collect the order from the buyer and it is too difficult to collect the order from the buyer. Some time Beximco people need to go abroad for collect the order. Document must be necessary all of the function. Buyer firstly searches on the web page of Bexinco Textile Limited and they collect the necessary information from the web site. Then they give the order by using buying house. So they need to prepare such type of document and Bexico also prepare such document varies on the buyer document. According to the buyer aspect company try to prepare the fabric. In the fabric processing stage they need to collect dispo number, design, layout, cad, swatch, sample, cost related document etc. For this reason marketing section need to prepare sample form, requisition form, swatch request form etc. So all document and fabric making process complete very carefully.

As product marketer, BTL should maintain reasonable flexibility in blending the elements of its marketing management to cope with the changing needs of the markets. A pragmatic approach in this direction warrants continuous and regular evaluation of dynamic technological and socioeconomic millennium.

Business line of this company in manufacturing and marketing of high quality fabric, which have large, yet share in textile sector in Bangladesh. If the BTL wants to complete with world class textile industries, they must have analyzed about marketing distribution channel, price margin maintains by them and the promotional activities given to traders etc, In order to know the current marketing management system of this companies they must have to do market research.

Beximco enter to the world market of textile and RMG is about 30 years. In these years we have faced lot of challenges and have got lot of experience. After crossing this time now we have get the golden time to re-infrastructure and reshape our whole industry and make a revolution. It is the appropriate time when we should think about our future industry newly. Keeping these things mind I have tried and designed my report on textile industries. It is not only my course requirement of BBA but also a step towards my professional career. I always believe that it will definitely add some values in my future goals.