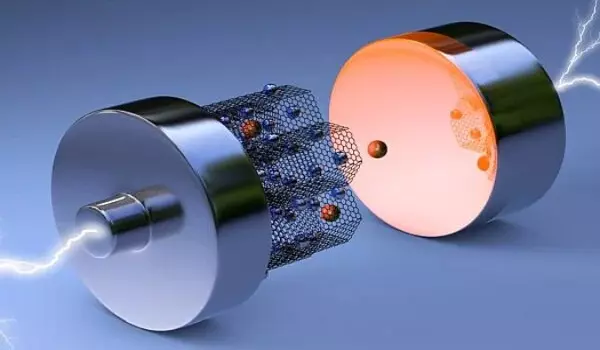

A novel design for microbatteries can improve their power and energy density, making them more suitable for use in small electronic devices such as smartphones and wearable technology. This design can include the use of new materials, such as graphene, and new configurations of the battery’s components. Additionally, innovations in manufacturing techniques can also play a role in the development of more powerful microbatteries.

The ability of batteries to power microdevices, microrobots, and implantable medical devices has long been hampered by the difficulty of translating the electrochemical performance of large format batteries to microscale power sources. Researchers developed a high-voltage microbattery (> 9 V) with unprecedented energy and power density compared to any existing battery design.

The ability of batteries to power microdevices, microrobots, and implantable medical devices has long been hampered by the difficulty of translating the electrochemical performance of large-format batteries to microscale power sources. Researchers at the University of Illinois at Urbana-Champaign have developed a high-voltage microbattery (> 9 V) with unprecedented energy and power density.

Material Science and Engineering Professor Paul Braun (Grainger Distinguished Chair in Engineering, Materials Research Laboratory Director), Dr. Sungbong Kim (Postdoc, MatSE, currently assistant professor at Korea Military Academy, co-first author), and Arghya Patra (Graduate Student, MatSE, MRL, co-first author) recently published their paper “Serially integrated high-voltage and high-power miniature batteries” in Cell Reports Physical Science.

Our research bridges the knowledge gap at the intersection of materials chemistry, unique materials manufacturing requirements for energy dense planar microbattery configurations, and applied nano-microelectronics that require a high-voltage, on-board type power source to drive microactuators and micromotors.

Dr. Sungbong Kim

The team demonstrated hermetically sealed (tightly closed to prevent exposure to ambient air), long-lasting, compact lithium batteries with an extremely low package mass fraction in single-, double-, and triple-stacked configurations with unprecedented operating voltages, power densities, and energy densities.

“We need powerful tiny batteries to unlock the full potential of microscale devices,” Braun says, “by improving electrode architectures and developing innovative battery designs.” The issue is that as batteries get smaller, the packaging takes over the volume and mass of the battery, while the electrode area shrinks. As a result, the battery’s energy and power are drastically reduced.

In their unique design of powerful microbatteries, the team developed novel packaging technology that used the positive and negative terminal current collectors as part of the packaging itself (rather than a separate entity). This allowed for the compact volume (? 0.165 cm3) and low package mass fraction (10.2%) of the batteries. In addition, they vertically stacked the electrode cells in series (so the voltage of each cell adds), which enabled the high operating voltage of the battery.

Another way to improve these microbatteries is to use very dense electrodes that provide high energy density. Polymers and carbon additives occupy nearly 40% of the volume of normal electrodes (not active materials). Braun’s group has grown electrodes that are fully dense and free of polymer and carbon additives using an intermediate temperature direct electrodeposition technique. These fully dense electrodes have a higher volumetric energy density than commercial electrodes. The dense electroplated DirectPlateTM LiCoO2 electrodes used in this study were manufactured by Xerion Advanced Battery Corporation (XABC, Dayton, Ohio), a company spun out of Braun’s research.

Patra mentions, “To date, electrode architectures and cell designs at the micro-nano scale have been limited to power dense designs that came at the cost of porosity and volumetric energy density. Our work has been successful to create a microscale energy source that exhibits both high power density and volumetric energy density.”

An important application space of these microbatteries includes powering insect-size microrobots to obtain valuable information during natural disasters, search and rescue missions, and in hazardous environments where direct human access is impossible. Co-author James Pikul (Assistant Professor, Department of Mechanical Engineering and Applied Mechanics, University of Pennsylvania) points out that “the high voltage is important for reducing the electronic payload that a microrobot needs to carry. 9 V can directly power motors and reduce the energy loss associated with boosting the voltage to the hundreds or thousands of volts needed from some actuators. This means that these batteries enable system level improvements beyond their energy density enhancement so that the small robots can travel farther or send more critical information to human operators.”

“Our research bridges the knowledge gap at the intersection of materials chemistry, unique materials manufacturing requirements for energy dense planar microbattery configurations, and applied nano-microelectronics that require a high-voltage, on-board type power source to drive microactuators and micromotors,” Kim adds.

Braun, a pioneer in battery miniaturization, concludes: “The current design of our microbattery is well-suited for high-energy, high-power, high-voltage, single-discharge applications. The design will then be translated to all solid-state microbattery platforms, which are inherently safer and more energy dense than liquid-cell counterparts.”