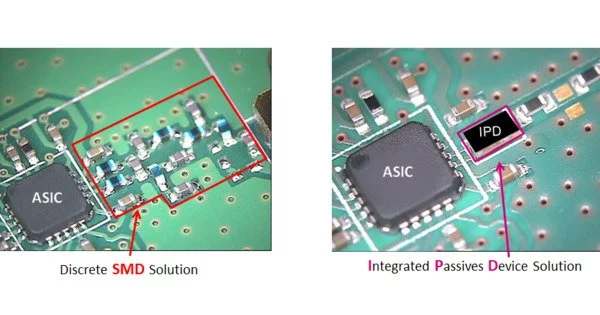

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components that include resistors (R), capacitors (C), inductors (L)/coils/chokes, microstriplines, impedance matching elements, baluns, or any combination of these components. IPDs are electronic components that are integrated directly onto a substrate or chip, combining multiple passive components into a single device.

Integrated passives are sometimes referred to as embedded passives, and the distinction between the two is technically ambiguous. Passives are realized in both cases between dielectric layers or on the same substrate. Passive electronic components do not need a power source and do not amplify or control electrical signals. They are made up of resistors, capacitors, and inductors.

IPDs began as resistor, capacitor, resistor-capacitor (RC), or resistor-capacitor-coil/inductor (RCL) networks. Passive transformers can also be built as integrated passive devices, such as by stacking two coils on top of each other and separating them with a thin dielectric layer. Diodes (PN, PIN, zener, etc.) can sometimes be integrated on the same substrate as integrated passives, especially if the substrate is silicon or another semiconductor such as gallium arsenide (GaAs).

By combining multiple passive components into a single package, IPDs are intended to reduce the size, weight, and cost of electronic systems. Passive components have traditionally been discrete, which means they are separate components mounted on a circuit board. IPDs provide several benefits by integrating them, including:

- Miniaturization: IPDs enable electronic system miniaturization by combining multiple passive components into a single package. This is especially useful in applications requiring small size and weight, such as mobile devices, wearables, and Internet of Things (IoT) devices.

- Performance: IPDs can reduce parasitic effects such as stray capacitance and inductance by directly integrating passive components onto a substrate or chip. This can improve overall circuit performance by lowering signal losses and increasing signal integrity.

- Cost and Manufacturing Efficiency: IPDs can reduce the number of discrete components that must be assembled and soldered onto a circuit board, thereby simplifying the manufacturing process. This can save money on component procurement, assembly time, and labor costs.

- Signal Integrity: Impedance matching and signal integrity can be improved with IPDs, particularly in high-frequency applications. Impedance matching can be optimized by integrating passive components close to active components, such as amplifiers or RF circuits, resulting in improved signal transmission and reduced reflections.

Wireless communication devices, RF front-ends, consumer electronics, automotive electronics, medical devices, and other electronic systems use IPDs. The specific types and configurations of passive components integrated into an IPD are determined by the target application’s requirements.

Overall, Integrated Passive Devices provide a compact and efficient solution for integrating passive components, improving performance, lowering costs, and enabling miniaturization in a variety of electronic systems.