INTRODUCTION

By means of the practical knowledge it’s possible to apply the theoretical knowledge in the practical field. For any technical education practical experience is almost equally important in association with the theoretical knowledge. The training minimizes the gap between theoretical and practical knowledge and makes us familiar with the industrial environment, we got an opportunity to complete 6 weeks (42 days) long industrial training and I did it in Asian specialized textile mills limited which is consists of Fabric manufacturing (yarn twisting, warping, sizing and weaving) units. It has well planned & equipped. It also has a sister spinning factory.

The industrial attachment is the process which builds understanding skill & attitude of the performer, which improves his knowledge in boosting productivity & services. College education provides us vast theoretical knowledge as well as more practical attachment, despite all these industrial attachment help us to be familiar with the technical support of modern machinery, Knowledge about various operation stages.

It also provides us sufficient practical knowledge about production management, Productivity evaluation, work study, efficiency, industrial management, production planning & control, production cost analysis, inventory management, purchasing, utility & maintenance of machinery and their operation techniques etc. the above mentioned cannot be achieved successfully by means of theoretical knowledge only. This is why it should be accomplished with practical knowledge in which it is based on industrial attachment makes us reliable to be accustomed with the industrial atmosphere & improve courage & inspiration to take self responsibility.

COMPANY NAME

Asian specialized textile mills limited

Corporate Headquarters

Dilkusha centre

28 Dilkusha C/A, 4th floor, Motijheel, Dhaka-1000 Bangladesh

Tel : +880-2-9558534, +88-2-9566052

Local office

28, Kmartuli lane,Islampur, Dhaka-1000

Tel: +880-2-7393678, +088-2-7393240

Factory

West muktarpur, Munsigaung, Dhaka, Bangladesh.

Coverage area of total factory 2,87,496 sft

Date of Establishment

January 1993

Commercial Production

1994.

Owner

MD: Harun- ur – rashid

Business line

Manufacturing and Marketing of high Quality Fabrics.

Listing status

Private Textile mills.

Authorized capital in taka 3000 million.

Paid up capital 10 millions.

Main Market

Local market, Europe.

Company Vision

Quality is always the combination of the highest intent, sincerest effort with an accurate execution

Product/Service:

Courser plain fabric, Shirting fabric, Twill (2/2, 3/2, 3/1)

Production capacity

20000 yd/day

Major buyer:

C&A

Zara

Matalan

All star

A to Z

Protile

Army tender

Human resource &organization structure:

Organizational structure:

Management system:

- Intercom telephone

- Fax

- Written letters

Raw materials:

Types of raw materials processed here,

Cotton 100% combed or carded.

Polyester-cotton bland (P/C or T/C); P=65% and C=35%

Viscose cotton (CVC); P=40% and C=60%

Sources of raw material:

- Ashik knit composite

- RK spinning

- Keya cotton mill

- Jamuna spinning mill

- Pakiza cotton mill

- Al razi textile

- Asian cotton mill

- Nahid cotton mill

- Shamim cotton mill

- Ajij twisting

- Hosain twisting

- Loyal spinning

- Ginni spinning

Machine and equipment:

warping

The parallel winding of a set of warp yarns from many yarn packages (cone/cheese) on a flanged bobbin (warping beam) at uniform specific tension and length is called Warping.

Objects:

- Wind the warp yarns on the warping beam to make it suitable for sizing.

- In case of designable fabric wind the yarns section wise by sectional warping.

Requirement of Warping:

- The yarns in the sheet should be in uniform spacing.

- The yarns in the sheet should be in uniform tension.

- The yarns in the sheet should be of a predetermined length.

- The sheet should be containing a predetermined number of ends.

- There should be no broken ends in the beam.

Types of Warping:

- DIRECT OR HIGH SPEED OR BEAM WARPING:

Direct warping is used for single color warping. Yarns are directly wound on the wrapers beam so it’s called direct warping.

- SECTIONAL OR PATTERN OR DRUM WARPING:

Sectional warping is used for complex color patterns. Sections are made sequentially according to warp pattern.

Raw Material:

- Cone (different count yarn) from Hard Winding Section.

Type-1

Brand: gusken

Model: 16332

Country: German

Creel capacity: 512

Speed: 150rpm

No of machine: 02

Type of warping: sectional warping

Type -2

Brand: beninger

Model: 10587

Country: Germany

Creel capacity: 512

Speed: 120rpm

No of m/c: 02

Type of warping: sectional warping

High speed directs warping:

Brand: fchlafhorft

Model: 05813

Country: Italy

Creel capacity: 810

Speed: 220 rpm

No of m/c: 01

Sizing:

Sizing is the process of giving a protective coating on the warp yarn to minimize yarn breakage during weaving.

Sizing is the most important operation in preparing warp yarn for weaving especially with cotton yarn. The smallest error in sizing process may be very harmful. This may increase warp breakage rate on the looms and consequently reduce weaving production and quality. Therefore sizing is termed as the “mother of Weaving”.

Objects:

- To increase the smoothness of the warp yarn.

- To reduce hairiness of warp yarn.

- To increase the strength of warp yarn.

- In some cases sizing is now done to modify the character of the warp yarn. i.e. to have an effect on fabric weight on fabric weight, stiffness, handle properties etc.

Requirement of sizing:

- Sized warp must be strong and elastic.

- Yarn strength and loss in elongation should be within admitted limits.

- The process must ensure the applications of required amount of size on the yarn.

- The tension of warp yarn must be constant all the time.

- The weavers beam must have a cylindrical shape, necessary winding density and the yarn length.

- The sizing process must be efficient, economical and must ensure the production of high quality size warps.

Machine description

Brand: ramallumin

Model: 085521

Country: Italy

Back beam: 16

Speed: 280 rpm

Size bath: 02

Heating r/r: 09

No of m/c: 02

Types of sizing:

Sizing may be classified into four types on the basis of size% on the yarn.

1. Light Sizing : 10% to 15%.

2. Pure Sizing : 16% to 25%.

3. Medium Sizing : 26% to 50%.

4. Heavy Sizing : 50% to 100%.

Sizing Recipe:

Sizing recipe depends on yarn type, total ends.

Typical sizing recipe-

In 500 Liter Water

- Starch : 10-20% of water.

- Binder : 2-4% of water.

- Softener : 0.5-1% of water.

SIZING RECIPE FOR A SPECIFIC FABRIC CONSTRUCTION USED IN ASIAN TEXTILE-

- Fabric construction : 20×20/128×90.

Fabric type : Solid dyed.

Total ends : 7552.

Avetex-K : 25 Kg.

Kollotex-5 : 25 Kg.

Quicksolan-SPR : 25 Kg.

Trisize : 12 Kg.

Sol-wax : 05 Kg.

Water : 430 Liters.

- Fabric construction : 45×342/108×52 cvc.

Fabric type : Yarn dyed.

Total ends : 7050.

Avetex-K : 25 Kg.

Kollotex-5 : 25 Kg.

Quicksolan-SPR : 25 Kg.

Trisize-SY 300H : 15 Kg.

Glissofil Extra Soft (wax : 05 Kg.

Water : 400 Liters.

- Fabric construction : 402x402/82×46.

Fabric type : Solid dyed.

Total ends : 5074.

Amisol : 25 Kgs.

Penetrose : 25 Kgs.

PVA : 16 Kgs.

Acrylic Polymarin Primer Form:10 Liters.

Artificial wax : 04 Kgs.

Water : 460 Liters.

Weaving:

Weaving is the process of manufacturing woven fabric by interlacing at two sets of yarns (warp & weft) at right angle (90°) according to design.

Objects:

- To produce woven fabric.

- To give the final product.

Requirement of Weaving:

- Proper sized warp yarn.

- Required length of warp yarns.

- Accurate drawing & denting.

- Machine setting must be accurate.

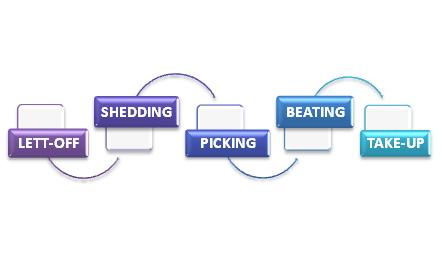

Weaving Process Involves:

Machine specification:

Loom type -01

Sulzer-ruti

F-2001

FK-1N-140G

Sulzer Brothers Ltd.

Winterthur Switzerland

Shedding type: tappet(cam)

Shed type: open

Weft insertion: by rapier (flexible, tip transfer)

Cam position: left side top position

Loom width: 63 inch

Held frame capacity: 06

Loom R.P.M.: 245

Weavers beam leangth: 140 cm

Total no of m/c: 44

Shed no: 01

Loom type 02

Sulzer ruti

Projectile weaving machine

PS 7100

Sulzer brothers Ltd.

Winterthur Switzerland

Shedding type: cam shedding

Shed type: open shed

Weft insertion: by projectile

Loom width: 65*2 inch (Double beam)

Heald frame: 10

Loom R.P.M.:350

Weavers beam length: 170*2 cm

Total no of m/c: 48

Shed: 02

Loom type 03

Sulzer ruti

Rapier weaving machine

G6100

Sulzer brothers Ltd.

Winterthur Switzerland

Shedding type: cam shedding

Shed type: open shed

Weft insertion: by rapier

Loom width: 65 inch

Heald frame: 10

Loom R.P.M.:400

Weavers beam length: 170 cm

Total no of m/c: 25

Shed: 03

Loom type 04

Sulzer ruti

Projectile weaving machine P.U

143 VSD S-110 KR D1

Sulzer brothers Ltd.

Winterthur Switzerland

Shedding type: Dobby shedding

Dobby type: Double lift single jack (positive)

Shed type: open shed

Weft insertion: by projectile

Dobby position: left side top position

Loom width: 65*2 inch (Double beam)

Heald frame: 20

Loom R.P.M.:280

Weavers beam length: 170*2 cm

Total no of m/c: 21

Shed no: 04

Operation Procedure:

- As a new beam is set to a loom either by drawing cam getting or tying, it is the task of loom technician to check & set all necessary setting, gauging & operating values through loom function panel & mechanical means. After all setting has been done, the loom function is checked by slow running or inching. The first meter of fabric is made normal running & cut off from the loom & checked over an inspection box against light.

The fabric is checked visually for-

Any wrong pattern setting.

Any wrong drawing & denting.

Fabric width, warp & weft density.

Any other cloth defect.

Any fault found in the fabric is corrected over the loom & it is handed over to the operator for normal running.

Production department:

Description of production process:

In every mill, there maintains a sequences in production processing. It is also followed in this mill where we were in industrial attachment. The process sequences are in list below:

1) Firstly, weaving manager gets a production shit from the merchandiser as accordance as consumer requirements then he informs or orders production officer about it.

2) Production officer informs technical in charge and knows about machine in which the production will be running.

3) Technical in charge calls for leader of mechanical fitter troops, they two take decision about machine for production considering machine condition, production capacity, maintenance complexity, etc.

4) Production officer with experienced mechanical fitter adjusts required design and cam setting for required fabric.

5) Supervisor checks daily production regularity and make operator conscious about finishing tin due time.

6) Operators operate machine in high attention as if there were no faults in the fabrics. If he thinks or sure about any fabric fault, then he calls for the mechanical fitters in duty. Mechanical fitter then fixes it if he can or he informs technical in charge. Then he comes in spot.

7) After required production and final inspection in 4-point system, they sent in dyeing factory.

Production Parameters in weaving

This section plans for woven production. Following parameters are important for the planning of weaving the fabric-

Order quantity (required amount of fabric)

Type of fabric to be knitted (plain, twill, canvas, shirting)

No of machine to be used

Type of yarn used

Sources of yarn

Fabric width

Types of Fabrics Produce in Asian:

Plain

Twill

Canvas

Rib stop

Shirting

The products which are available in weaving floor are given below:

| Fabric construction | Design | Sample | ||||||||||||||||

| 40/2*40/2/120*60 | 3/1 twill

|

| Fabric construction | design | sample | ||||||||||||||||

| 20*20/100*50 | Canvas 1/1

| |||||||||||||||||

| 16*10/100*50 | 3/1 twill

| |||||||||||||||||

| 150/2*150/2/110*72 | 2/2 twill

| |||||||||||||||||

| 150/2*150/2/110*72 | 2/1 twill

| |||||||||||||||||

| 45/2*45/2/120*75 | 3/1 twill

|

Production calculation:

Production:

Efficiency

Calculation:

Fabric construction: 20*20/110*56

Loom speed : 330 rpm

Efficiency : 88%

No of loom : 22

Time : 1 shift (12 hr)

So,

Production=

=2086 meter/shift

Inspection and checking:

Type of fabric defects:

Fabric defects can be classified into three groups:

Avoidable and unavoidable

Major and minor

Mend able and emendable

Table of classification of major and minor defect:

| Types of defects | minor | major |

| stains | At more than one place | |

| Missing ends | 1-3 cm | More than 3cm |

| cracks | 1-2 cm | More than 2 picks |

| Thick place | Up to packs for lighter variety | More than 3 picks |

| Broken picks | Less than half the width of fabric | More than half the width of fabric |

| Floats/stitches | Less than 1 cm | 1-5 cm |

| slabs | 2 slab in weft of size Less than 1cm | More than 2 slab in weft of size 1 cm or more |

| Filament rupture | More than one place | |

| Double pick | Occurring less frequently | Occurring more frequently |

Causes of faulty fabric:

- Uneven shedding

- Rough surface of slay race

- Too early or too late Picking

- Damage reed

- Jerky movement of heald frame

- Poor yarn quality

- Faulty preparation of beam

- Improper atmosphere condition

- Improper functioning of weft stop motion

Quality management

Quality assurance system of knitting division:

The quality assurance department is assigned to maintain consistently uniform quality of the material in process and various stages of its manufacturing. After collecting fabric rolls from different machines, these fabrics need to inspect thoroughly by the quality inspectors to assure required quality before dying. Quality assurance of woven grey fabric is described here.

Object Quality control:

- For research

- 2. Selection of new materials for process control

- For process development

- Process development

- Product testing

- Specification test

- Product listing

On- line:

- Grey GSM of the fabric

- Grey inspection

- Stitch length

- In coming good quality check

Off-line tests are:

All off-line tests for finished fabric can be grouped as follow:

- Shrinkage test

- Pilling test stretch ability & growth recovery

- Smoothness appearance.

Utility Services:

Utility Section

- Generator

- Boiler

- Air Compressor

- Generator

An electrical generator is a machine that converts mechanical energy of power into electrical energy or power.

- Machine No: 01

- Brand Name: Waukesha

- Capacity: 1125 KVA

- Machine No: 02

- Brand Name: Cater Pillar

- Capacity: 390 KVA

- Boiler

- Brand Name: Cleaver Brooks

- Origin: USA

- Capacity: 10000 Kg/hr

- Specification:

- Feed Water Temperature: 60°C

- Feed Water Hardness: 2

- Steam Pressure: 500 PSI

- Types of Steam: Wet System

- Steam Temperature: 150°C

- Fuel Used: Natural Gas

Air Compressor

An air compressor is a m/c to compress the air and to raise its pressure. The air compressor sucks air from the atmosphere, compresses it and delivers the same under in high pressure to a storage vessel. From a storage vessel, it may be conveyed by the pipeline to a place where the supply of compressed air required.

Machine Parts

Motor & Piston

Compressed Air

Oil Drain Plug

Air compressor

Brand: jukai

Origin: china

Company: shenzhue jukai CO. LTD.

Maintenance

Maintenance:

The act which is done to Keep the factory plan equipments machine tools etc. in an optimum working condition, minimize the breakdown of m/c’s to improve Productivity of existing m/c tools and avoid sinking of additional capacity and to Prolong the useful life of the factory plant & machinery is called Maintenance.

Objectives of Maintenance:

- To Keep the factory Plants, equipments, Machine tools in an optimum working condition.

- To ensure specified accuracy to product and time schedule of delivery to customer.

- To keep the downtime of Machines to the minimum thus to have control over the production Program.

- To Keep the Production cycle within the stipulated range.

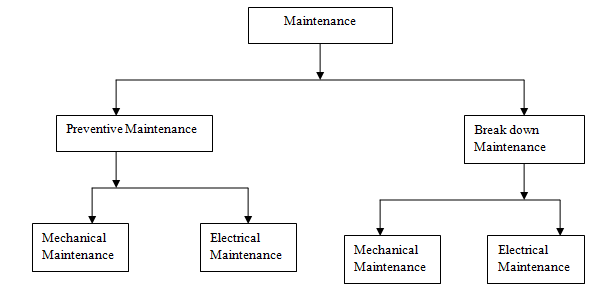

Classification of maintenance:

Daily Maintenance Test List:

- Checking the left & right selvedge for looseness due to wrong denting of leno selvedge.

- Fault checking in the woven fabric & working sure that there are no fabric fault like-

- Double pick.

- Miss pick.

- Stop mark.

- Weft loose.

- Temple mark.

- Reed mark.

- Checking the feeler eyes cable, make sure that there is no fluff over the feeler eye & the cable is not loose.

- Checking the warp sheet opening & closing, make sure that the cycle it is following is of the required specific degree (0⁰-90⁰-170⁰-290⁰).

- Checking for abnormal noise, also any loose nut & bolt.

- Checking of warp & weft stop. Remove the cause if those are above the standard. The standard stops are 25, 20, 15 for weft feeler 1, warp, and weft feeler 2 respectively.

- Checking oils leakage from cam box, dobby, gear box & let-off box.

Maintenance Tools & Equipments and their functions:

1. Combination tools (Spanner)

Function: Tightening & Loosening of Nuts & bolts

2. Socket Ratchet set

Function: Tightening of Nuts & bolts

3. Wrench

Function: Tightening & Loosening of Nuts & bolts

4. Pliers

Function: Tightening & Loosening of Nuts & bolts

5. Pipe Cutting Tools

Function: For Pipe Cutting.

6. Divider

Function: For circle marking on metal & wood

7. Oil Can

Function: Oiling of moving Parts.

8. Drill M/C and Drill bit.

Function: For Drilling.

9. Grease Gum.

Function: For greasing of moving Parts of M/C

10. Girding M/C

Function: For grinding & Cutting of mild steel.

11. Welding M/C

Function: For welding & Cutting.

12. File

Function: For Smoothing the Surface.

13. Hammer

Function: For Scaling & right angling.

14. Hacksaw blade.

Discussion:

Asian specialized textile LTD. is the largest and most versatile business conglomerate in the private sector in BANGLADESH. Asian textile is committed to the best human workplace practices. Their goal is to continuously improve their Human Resource policies and procedures through education, training, communication and employees involvement. Right from inception the policy of the company has been to provide total customer satisfaction by offering quality woven in time. Working on new concepts in styling & content of the woven garment is a continuous activity in Asian textile. with an objective to up the quality & the value of merchandise. To meet the commitments of quality & prompt delivery Asian textile Ltd. decided to integrate the manufacturing process in a planned manner. Over the year the entire process has been integrated by importing sophisticated machinery from world-renowned manufacturers. For achieving their goal, Asian textile. Has recruited a high profiled human resource team. The production is controlled by technical persons. All of the decision makers of production sector in Asian textile Ltd. are textile graduates. According to their capacity they have an enriched production team which is very rare in other factories of BANGLADESH. The working environment of Asian textile Ltd. is very cordially & friendly. All of the executives & employees of Asian textile Ltd. Are very much cordial & they always appreciating the learners.

LIMITATIONS:

- In our industrial attachment program contents some secret of factory is included. To collect this information like history of project development, costing of products, marketing strategy etc. every student face a great problem as it is a secret. So our proposal for our University authority to exclude these topics from the contents.

- We had a very limited time. In spite of my willing to study more details it was not possible to do so.

- This while process is not possible to bind such a small frame as this report, hence our effort spent on summarizing them.

Conclusion

Industrial attachment program send us to the expected destiny of practical life. The completion of tow month industrial attachment at Asian textile Ltd I have got the impression that the factory is one of the most modern woven project in Bangladesh. It has earned very good reputation for its best performance over any other woven project.

During my industrial attachment program I had tried to my best to done my duty. My supervising officer also satisfied to me & offer co-operation in every steps. It is completely a new experience in my life, which will be very effective in my service life. During my training period I realized that practical experience is more valuable for service life.