A hydrophobic molecular sieve is a type of material that has the ability to selectively adsorb and separate molecules based on their size and polarity, while also repelling water molecules. These materials are commonly used in various industrial processes such as gas drying, solvent drying, and air purification.

Polydimethylsiloxane (PDMS) has been used in the research of high performance humidity resistant hydrogen sulfide (H2S) sensors by a research team led by Prof. Meng Gang from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, opening the door for the practical applications of H2S chemiresistors in an ambient humid air atmosphere.

The results have been published in ACS Applied Materials & Interfaces and Chemical Communications.

H2S is a colorless, flammable, explosive, highly corrosive, and highly toxic gas that is widely found in semi-closed and high humidity environments. Some oxides, including delafossite, ZnO, and CuO, have a high sensitivity to H2S in dry air, but humidity tends to interfere with the response of the sensors.

H2S is also a very corrosive gas, and its corrosiveness rises as the humidity level rises. This causes sensors to corrode and degrade quickly in high humidity conditions, which poses a significant obstacle to the practical use of sensors.

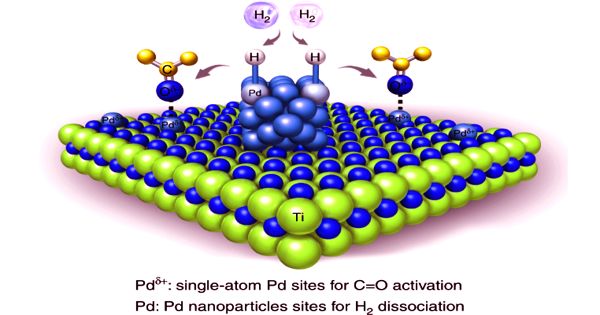

In order to address these issues, the researchers used the thermal evaporation approach to produce a hydrophobic and semi-permeable PDMS membrane on the Pt single atom-anchored cupric chromate (CuCrO2).

Zhang Ruofan, first author of the study, described the biofunctional role of PDMS as “killing two birds with one stone.”

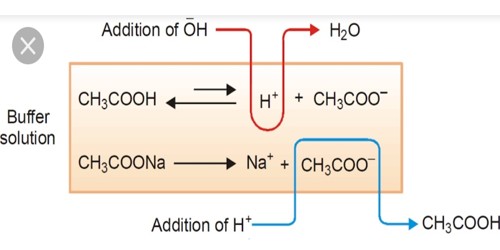

PDMS had a hydrophobic nature. It may greatly enhance the sensor’s long-term stability in a humid environment, effectively isolate the penetration of water vapor in the environment, and reduce the impact of environmental humidity on the sensor.

On the other hand, the PDMS membrane’s micropores could successfully block methyl mercaptan molecules with a diameter somewhat bigger than that of H2S. It acted as a

“molecular sieve,” further improving the selectivity of the sensor for H2S.

With its low operating temperature (100 °C), high response (up to 151 for 5 ppm H2S at 50% relative humidity), high selectivity, and good long-term stability, the humidity-resistant H2S sensor based on PDMS-coated CuCrO2 laid a crucial foundation for the practical application of H2S sensors in petrochemical, natural gas, and other fields.