Embrittlement is the process of a material becoming brittle due to a loss of ductility. It is a significant decrease of the ductility of a material, which makes the material brittle. It is most pronounced near room temperature and decreases at both lower and higher temperatures. It is primarily the consequence of radiation defects that both cluster and accelerate solute clustering and precipitation of copper-rich phases. Common embrittlement is encountered in galvanized steel, which is related to cold working, aging, and hydrogen absorption.

Embrittlement is the loss of a material’s ductility, due to a chemical or physical change, leading to crack propagation without appreciable plastic deformation.

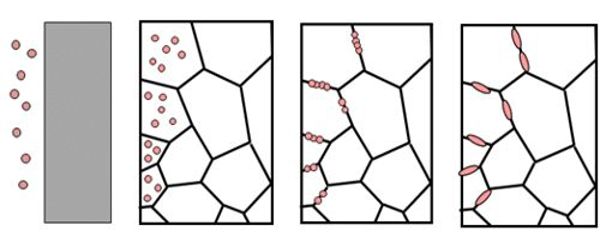

Embrittlement is used to describe any phenomena where the environment compromises a stressed material’s mechanical performance, such as temperature or environmental composition. An embrittlement correlation method is a technique to calculate the expected amount of neutron irradiation embrittlement for the material of interest at a given time using the information on the material chemistry, irradiation conditions, etc. It is primarily the consequence of radiation defects that both cluster and accelerate solute clustering and precipitation of copper-rich phases.

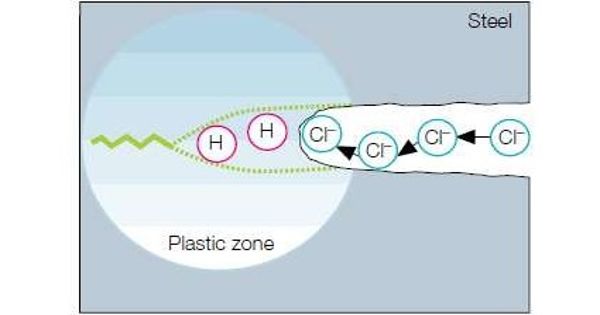

Embrittlement due to oxidative aging results from the loss of polymer capacity to undergo plastic deformation. This is oftentimes undesirable as brittle fracture occurs quicker and can much more easily propagate than ductile fracture, leading to complete failure of the equipment. It is an effect usually observed with metallic materials (metallic lattice) when exposed to hydrogen atoms which can be dissociated from HCl, HCN, H2S, or H2. It occurs suddenly, which indicates the existence of a critical state separating ductile and brittle regimes of deformation. The primary embrittlement mechanism of plastics is the loss of plasticizers by aging or overheating, and the primary embrittlement mechanism of asphalt is by oxidation, which is severe in warmer climates.

The embrittlement of materials can be caused by low temperatures. When liquid hydrogen or cold gas is involved in a device, the materials of construction must retain a certain amount of elasticity at the operating conditions if the parts made from them are to withstand the incumbent stresses or forces. Various materials have different mechanisms of embrittlement, therefore it can manifest in a variety of ways, from slow crack growth to a reduction of tensile ductility and toughness. The embrittlement of steel by hydrogen only manifests itself during processes that lead to the fracture of the metal; it does not, for example, increase the hardness as measured by an indentation test.

Information Source: