Electrostatic discharge (ESD) refers to the sudden flow of electric charge between two objects with different electrical potentials. It occurs when there is a buildup of static electricity on an object, and that charge is discharged through a conductive path. ESD can happen in various situations and can potentially cause damage to electronic devices, components, or systems.

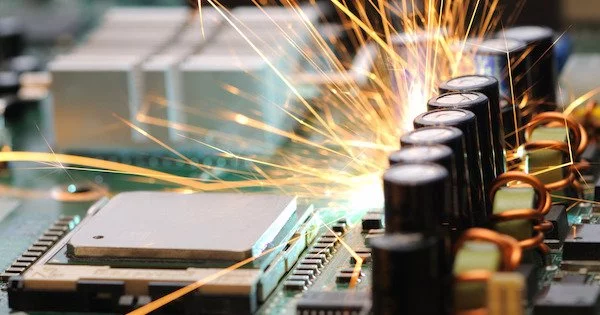

ESD is a brief flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. Static electricity can be generated by tribocharging or electrostatic induction. When differently charged objects are brought close together or when the dielectric between them fails, ESD occurs, often resulting in a visible spark.

ESD can produce spectacular electric sparks (lightning with the accompanying sound of thunder is a large-scale ESD event), but it can also produce less dramatic forms that are not seen or heard but are large enough to damage sensitive electronic devices. Electric sparks require a field strength greater than 40 kV/cm in air, as seen in lightning strikes. Other forms of ESD include corona discharge from sharp electrodes and brush discharge from blunt electrodes.

Here are some key points about electrostatic discharge:

- Causes of ESD: ESD can be caused by a variety of factors, such as friction between materials, contact and separation of materials, or even atmospheric conditions. Common sources of static electricity include clothing, carpets, chairs, and other non-conductive surfaces.

- Electrostatic sensitivity: Electrostatic discharge is a common problem for electronic devices and components, particularly integrated circuits (ICs). Even very small electrostatic discharges that are imperceptible to humans can damage or destroy them. Because of this sensitivity, when working with sensitive electronics, proper handling procedures and precautions are essential.

- ESD damage: ESD can cause either immediate or latent damage to electronic devices. Immediate damage refers to a component’s visible and immediate malfunctioning or destruction, whereas latent damage refers to a component’s degradation or failure over time as a result of ESD exposure. Both types of damage can reduce a product’s reliability or lifespan.

- ESD protection measures: To prevent ESD-related damage, various protective measures are implemented. These include using antistatic wrist straps, grounded workstations or mats, and conductive packaging for sensitive components. ESD-safe handling practices, such as avoiding direct contact with sensitive parts and minimizing movement in environments with a high risk of static discharge, are also important.

It’s essential to take precautions against electrostatic discharge, especially when working with sensitive electronic components or devices. By following proper handling procedures and using ESD protection measures, the risk of ESD-related damage can be significantly reduced.