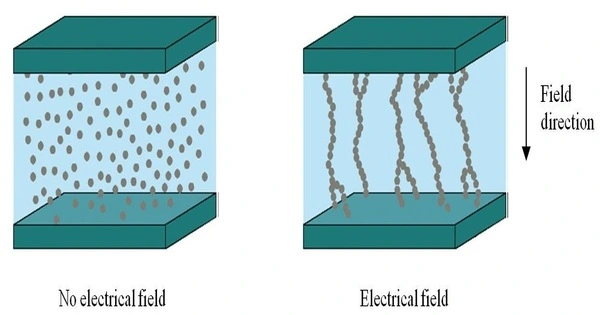

Electrorheological (ER) fluids are electrically insulating suspensions of extremely fine non-conducting but electrically active particles (up to 50 micrometres in diameter). These are a type of smart fluid that exhibit changes in their rheological properties, such as viscosity and flow behavior, in response to an electric field. In response to an electric field, the apparent viscosity of these fluids changes reversibly by an order of 100,000. These fluids are composed of suspensions of solid particles dispersed in a liquid or semi-liquid medium. A typical ER fluid, for example, can transition from a liquid to a gel and back, with response times on the order of milliseconds.

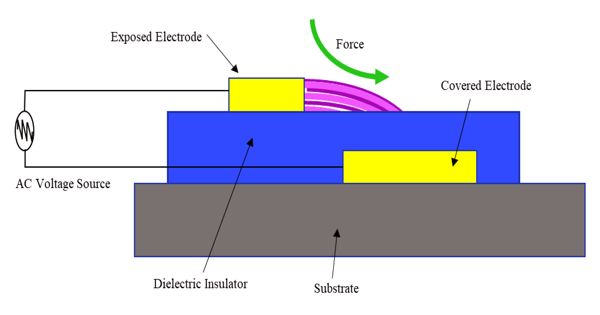

The effect is sometimes referred to as the Winslow effect after its discoverer, Willis Winslow, an American inventor who obtained a US patent on the effect in 1947 and published an article on it in 1949. The particles in an electrorheological fluid are typically polarizable, meaning they can align themselves in the presence of an electric field. When an electric field is applied to the fluid, the particles rearrange themselves into chains or columns, causing the fluid to become highly viscous or even solid-like. This behavior is known as the electrorheological effect.

The viscosity and flow characteristics of an electrorheological fluid can be controlled by adjusting the strength of the electric field. When the electric field is removed, the fluid returns to its original low viscosity state. This reversible behavior makes electrorheological fluids useful in a variety of applications where precise and rapid control of fluid properties is required.

Some of the potential applications of electrorheological fluids include:

- Dampers and shock absorbers: Electrorheological fluids can be used in suspension systems to provide adjustable damping forces in response to changing road conditions or other external factors. By varying the electric field, the viscosity of the fluid can be altered to provide different levels of damping.

- Clutches and brakes: Electrorheological fluids can be employed in clutches and brakes to provide variable torque transmission. By adjusting the electric field, the viscosity of the fluid can be modulated, enabling precise control over the engagement and disengagement of the clutch or brake.

- Haptic devices: Electrorheological fluids can be used in haptic interfaces or force feedback devices to simulate tactile sensations. By altering the viscosity of the fluid, it is possible to generate varying levels of resistance or texture, enhancing the realism of the haptic experience.

- Robotics and automation: Electrorheological fluids find applications in robotics and automation systems where precise control over fluid properties is essential. They can be used in soft robots, grippers, or valves to enable rapid adjustments in response to changing operational requirements.

- Energy absorption and vibration control: Electrorheological fluids can be utilized in devices designed to absorb and dissipate mechanical energy or dampen vibrations. They can be employed in automotive systems, building structures, or industrial machinery to improve safety, reduce vibrations, and minimize structural damage.

It’s worth noting that while electrorheological fluids offer significant advantages in terms of their controllability, they also have some limitations. These include the requirement for an external power source to maintain the electric field, potential wear of the particles over time, and the sensitivity of the fluid’s properties to factors such as temperature and particle concentration. Nonetheless, ongoing research and development in the field aim to address these challenges and expand the range of applications for electrorheological fluids.