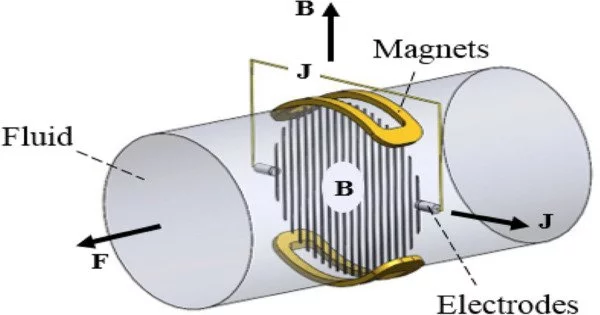

An electromagnetic pump is a pump that uses electromagnetism to move liquid metal, molten salt, brine, or other electrically conductive liquid. It is also known as a magnetohydrodynamic (MHD) pump, is a device that moves fluids using electromagnetic principles rather than moving parts. It creates a pumping action by interacting magnetic fields with electrically conducting fluids such as liquid metals or saltwater.

The basic idea behind an electromagnetic pump is to apply a magnetic field across a conducting fluid. A Lorentz force is experienced when an electric current passes through a fluid in the presence of a magnetic field. This force causes the fluid to flow through the pump by propelling it in a specific direction.

A magnetic field is created at right angles to the direction of movement of the liquid, and a current is passed through it. This produces an electromagnetic force that causes the liquid to move. Pumping molten solder in many wave soldering machines, pumping liquid-metal coolant, and magnetohydrodynamic drive are all applications.

Electromagnetic pumps have several advantages over traditional mechanical pumps, such as:

- No moving parts: Since there are no rotating components or impellers, electromagnetic pumps have no mechanical wear and tear, reducing the need for maintenance and improving reliability.

- High reliability: The absence of moving parts reduces the chances of mechanical failure, making electromagnetic pumps suitable for applications where reliability is critical.

- Precise control: The flow rate of an electromagnetic pump can be easily controlled by adjusting the strength of the magnetic field or the applied current. This allows for precise and responsive control of fluid flow.

- Compatible with corrosive fluids: Electromagnetic pumps can handle corrosive and abrasive fluids since there are no contact surfaces susceptible to wear or chemical attack.

However, electromagnetic pumps also have some limitations and considerations:

- Limited to conducting fluids: Electromagnetic pumps work effectively with electrically conducting fluids but are not suitable for non-conductive fluids like most gases and some liquids.

- Power requirements: Generating and maintaining the required magnetic field and applying the necessary electric current can consume significant amounts of energy, making electromagnetic pumps less efficient compared to some mechanical pumps.

- Fluid compatibility: The choice of fluid is crucial since the electrical conductivity and magnetic properties of the fluid impact the efficiency and performance of the electromagnetic pump. Certain fluids may not be compatible or may require additional considerations.

Applications

Aerospace, nuclear power, metallurgy, chemical processing, and water treatment are all industries that use electromagnetic pumps. They are commonly used for pumping liquid metals in nuclear reactors, circulating molten metals in metallurgical processes, and handling corrosive or hazardous fluids in situations where mechanical pumps would be ineffective.

While electromagnetic pumps have been studied and used in specific applications, they are not as common or widely used as traditional mechanical pumps due to their limitations and the unique requirements of conducting fluid systems.