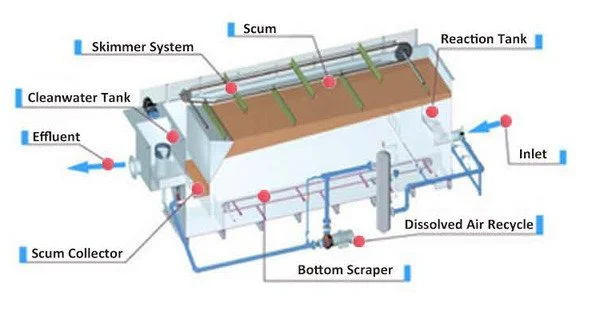

Dissolved Air Flotation (DAF) is a method of treating water that uses small air bubbles to remove suspended particles, oils, and other pollutants. It is a water treatment procedure that clarifies wastewaters (or other waterways) by removing suspended particles like oil or sediments. The procedure relies on buoyancy principles, in which suspended particles connect to air bubbles and float to the water’s top, generating a layer of sludge or froth that is readily removed.

The removal process involves dissolving air in water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air generates tiny bubbles that stick to the suspended stuff, leading it to float to the water’s surface, where it may be collected using a skimmer.

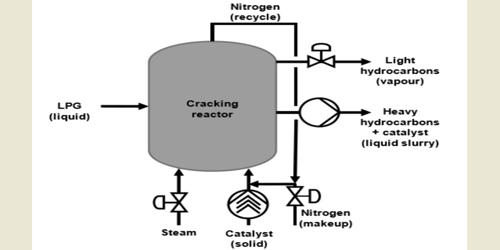

Dissolved air flotation is commonly used to treat industrial wastewater effluents from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment, and other industrial facilities. Induced gas flotation, a very similar procedure, is also used to remediate wastewater. Froth flotation is a typical method of treating mineral ores. Dissolved gas flotation (DGF) units in the oil sector do not employ air as a flotation medium due to the risk of explosion. Instead, the bubbles are created with nitrogen gas.

Here’s a basic overview of how the Dissolved Air Flotation process works:

- Coagulation and Flocculation: Prior to DAF, coagulants and flocculants are often added to the water to help agglomerate and form larger particles from the smaller suspended solids. This step enhances the efficiency of the flotation process.

- Dissolved Air Saturation: In the DAF tank, air is dissolved in the water under pressure. This is typically achieved by injecting air into the water or by using a pressurized recycle stream. The dissolved air forms tiny bubbles when the pressure is released.

- Bubble Attachment: The water with dissolved air is then released into the flotation tank, and as it enters the tank with lower pressure, the dissolved air comes out of solution in the form of tiny bubbles. These bubbles attach to the suspended particles, creating a buoyant force.

- Flotation and Separation: The buoyant particles rise to the surface, resulting in a coating of sludge or froth. This layer can then be mechanically removed from the surface for further processing or disposal.

- Effluent Discharge: Clarified water is normally collected from the bottom of the DAF tank and discharged after being effectively separated from suspended materials.

Dissolved air flotation is widely utilized in a variety of industries, including wastewater treatment plants, paper mills, food processing facilities, and others. It effectively removes a wide range of pollutants from industrial and municipal wastewater streams, including suspended particles, fats, oils, and grease. Additionally, DAF systems are adaptable to diverse flow rates and pollutant kinds.