Professor Junsuk Rho of the Departments of Mechanical Engineering, Chemical Engineering, and Electrical Engineering, Hyunjung Kang and Nara Jeon, PhD candidates from the Department of Mechanical Engineering, and Dongkyo Oh, a PhD student from the Department of Mechanical Engineering at Pohang University of Science and Technology (POSTECH), completed a thorough quantitative analysis. Their goal is to identify the best printing material for creating ultraviolet metasurfaces. Their findings appeared in the journal Microsystems & Nanoengineering.

These ultra-thin optical devices, known as metasurfaces, have the extraordinary ability to manipulate light at a nanoscale scale. Metasurfaces have long been researched as a key technology for the evolution of next-generation displays, imaging, and biosensing. Their capabilities extend beyond visible light to infrared and ultraviolet light.

Our future research endeavors will focus on refining the preparation conditions for optimal nanocomposites, thus propelling the advancement, application and expansion of optical metasurface fabrication technology.

Professor Junsuk Rho

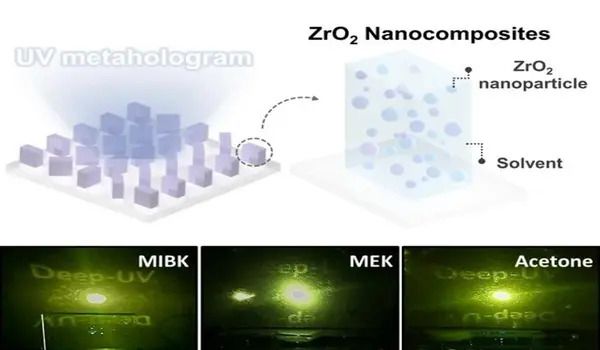

Nanoimprint lithography is a metasurface production process that works similarly to a stamp, producing many replicas from a single mold. This revolutionary technology promises low-cost, large-scale metasurface fabrication, opening the door for commercial viability. However, the resin used as a printing material has a low refractive index, which prevents efficient light management. To address this issue, researchers are actively investigating nanocomposites, which include nanoparticles into the resin to increase its refractive index. However, the success of this technique is dependent on several aspects, including nanoparticle kind and solvent selection, demanding a thorough investigation for optimal metasurface performance.

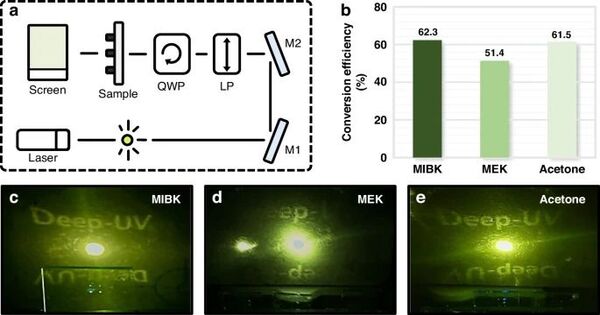

In their research, the team meticulously designed experiments to evaluate the impact of nanoparticle concentration and solvent selection on pattern transfer and UV metaholograms. Specifically, they manipulated the concentration of zirconium dioxide (ZrO2), a nanocomposite renowned for its effectiveness in UV metahologram production, ranging from 20% to 90%. The findings showed that the highest pattern transfer efficiency was attained at an 80% concentration level.

Furthermore, when ZrO2 was combined at an 80% concentration with various solvents such as methylisobutyl ketone, methyl ethyl ketone, and acetone for metahologram realization, the conversion efficiency increased dramatically in the ultraviolet spectrum (325 nm), reaching impressive levels of 62.3%, 51.4%, and 61.5%, respectively. This study is notable because it establishes an ideal metric for creating metaholograms that are specifically designed for the ultraviolet domain rather than the visible range, as well as pioneering the production of novel nanocomposites.

Professor Junsuk Rho from POSTECH remarked, “The use of titanium dioxide (TiO2) and silicon (Si) nanocomposites instead of ZrO2 expands the applicability to visible and infrared light.” He expressed expectation by stating, “Our future research endeavors will focus on refining the preparation conditions for optimal nanocomposites, thus propelling the advancement, application and expansion of optical metasurface fabrication technology.”