Chromium trioxide (also known as chromium(VI) oxide or chromic anhydride) is a very strong oxidizing agent, especially for organic matter; it ignites ethanol very instantly. It has the formula CrO3 and is an inorganic chemical. It’s the acidic anhydride of chromic acid, and it’s also known as chromic acid anhydride.

Anhydrous chromium trioxide is a dark purplish-red solid. The canisters may explode if they are exposed to fire or heat for an extended period of time. It’s manufactured by slowly adding concentrated sulphuric acid to an ice-cold concentrated aqueous sodium dichromate solution while stirring. After that, the mixture is filtered through sintered glass, washed with nitric acid, and dried in a desiccator at 120°C.

Sulfuric acid is used to produce chromium trioxide by processing sodium chromate or sodium dichromate:

H2SO4 + Na2Cr2O7 → 2 CrO3 + Na2SO4 + H2O

To evaporate water and separate the top layer of sodium bisulfate from the molten chromium(VI) oxide at the bottom, the temperature of the combination is kept above the melting point of chromium(VI) oxide. This or comparable pathways produce around 100,000 tonnes per year.

It’s an acidic oxide that dissolves in water to produce chromic acid, a potent oxidizing agent and glassware cleaner. Chromium(VI)oxide loses oxygen at 400°C and becomes chromium(III) oxide. It produces chromic acid and anhydrides in water, which are used to make salts like sodium dichromate (Na2Cr2O7) and pyridinium dichromate.

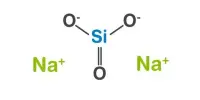

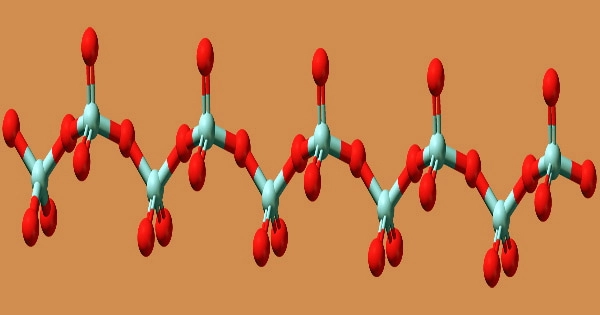

The solid is made up of vertices shared by chains of chromium atoms that are tetrahedrally coordinated. As a result, each chromium center shares two oxygen centers with its neighbors. The stoichiometry is 1:3 because two oxygen atoms are not shared.

The technique relies heavily on temperature control and heating duration. Temperatures above 197°C (melting point) or allowing the molten mass to settle for an extended period of time can cause the product to decompose.

Hexavalent chromium is present in chromium trioxide, which has a molecular weight of 100.01. It’s also known as chromic anhydride, chromic acid anhydride, and chromic acid, which is incorrect. To make chromic anhydride and sodium bisulfate, the sodium dichromate solution (70° Bé) and 98 percent sulfuric acid were separately introduced into the reactor with a stirring mechanism, swirled, and combined, and heated and melted by direct fire.

Sulfuric acid was added in a theoretical amount of roughly 102 percent, and the reaction end temperature was kept at 200205 °C. Stop heating and stirring when all of the materials have melted, allowing the material to stratify so that the lighter sodium bicarbonate floated on top while the heavier molten chromic anhydride was discharged from the reactor’s bottom valve, cooled, and solidified for tablets through the drum knotting machine, resulting in chromic anhydride products.

Density functional theory was used to calculate the structure of monomeric CrO3, and it was found to be pyramidal (point group C3v) rather than planar (point group D3h). The molten sodium bisulfate contains a trace of chromic anhydride, which can be crystallized and recovered after cooling.

For the manufacturing of basic chromium sulfate, the molten sodium bisulfate can be directly poured into water (be careful not to spill) and dissolved into a solution with a concentration of 4042 ° Bé. Hexavalent chromium is a strong oxidant since it is connected to oxygen; nevertheless, it does not form coordination compounds and can be easily reduced to chromium trioxide.

Chromium compounds can cause ulcers because they have a local mimicking impact on the skin and mucous membrane. Inhalation of this substance can cause perforation of the nasal septal aerosol cartilage, causing respiratory organ damage and potentially pulmonary sclerosis. Above 197 °C, chromium trioxide decomposes, releasing oxygen and eventually yielding Cr2O3:

4 CrO3 → 2 Cr2O3 + 3 O2

Chromium trioxide is soluble in tert-butyl alcohol, pyridine, and acetic anhydride, although caution must be exercised while using these solutions because they have a tendency to explode. Damage to the liver, kidneys, gastrointestinal tract and cardiovascular system are all signs of general toxicity. It can also cause conjunctivitis, which can result in blindness if it comes into contact with the eyes.

It’s utilized as an oxidant in organic synthesis, usually as a solution in acetic acid or, in the case of the Jones oxidation, acetone. If spilled on the skin, immediately rinse for 15 minutes with water. When eczema and dermatitis are present, lotion, dusting, and nonstimulating ointment should be administered topically.

Chrome trioxide has been widely used in chromium plating, particularly in the manufacture of vehicles. It’s usually used with additives that have an effect on plating but don’t react with the trioxide. The trioxide combines with cadmium, zinc, and other metals to form corrosion-resistant passivating chromate coatings.

Aluminium anodizing, particularly on military aircraft; chemical conversion coatings, which give both decoration and corrosion protection; and the formation of phosphate films on galvanized iron or steel are examples of other metal-finishing applications. It’s also utilized to convert primary alcohols to carboxylic acids and secondary alcohols to ketones.

It is utilized as a stripping agent for all sorts of anodic coatings and in the synthesis of syntheric rubies with phosphoric acid. It is used to limit microbial development in the wastewater storage tank on the International Space Station. The ideal stripping agent for all types of anodic coatings is a chromic acid/phosphoric acid mix.