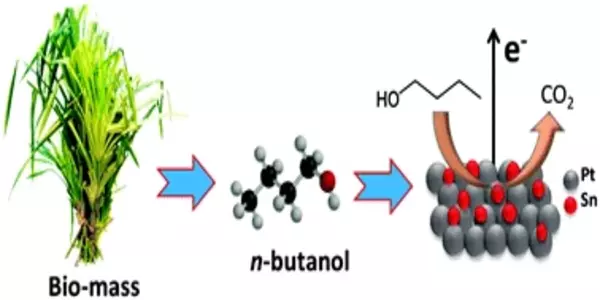

Butanol fuel is a biofuel that is derived from biomass such as corn or sugarcane. It is considered a “drop-in” biofuel, meaning that it can be used in existing infrastructure and vehicles without any modifications. Butanol has a higher energy content and a higher octane rating than ethanol, which makes it a more efficient fuel. It also has a lower vapor pressure, which means that it is less likely to evaporate and contribute to air pollution. However, the process of producing butanol from biomass is currently more expensive than the production of ethanol, which limits its commercial viability.

It is similar to gasoline in terms of energy content and can be used as a replacement for gasoline in internal combustion engines. Butanol has a higher energy density than ethanol, which means that it can provide more energy per unit volume, and it is also less volatile, which makes it less likely to evaporate and cause air pollution. Additionally, butanol can be blended with gasoline in any proportion, unlike ethanol, which can only be blended at a maximum of 10% with gasoline.

It can be used as a replacement for gasoline in internal combustion engines. One of the advantages of butanol fuel is that it has a higher energy content and a lower vapor pressure than ethanol, making it less prone to evaporation and better suited for use in cold temperatures. Additionally, butanol is less corrosive than ethanol and is less likely to damage engines. It can be blended with gasoline in any ratio, but typically it is blended at a ratio of up to 12% with gasoline to make it suitable for use in most gasoline engines.

Butanol has a higher energy content than ethanol and can be used in existing gasoline infrastructure without modification. However, it is not as widely used as ethanol as a biofuel due to its higher cost of production. It can be used as a substitute for gasoline in internal combustion engines. Butanol has several advantages over other biofuels, such as ethanol, including a higher energy content, better stability, and lower vapor pressure. However, it is also more expensive to produce, and there is currently less infrastructure in place to support its use as fuel.

Increasing butanol yields requires manipulating metabolic networks through metabolic engineering and genetic engineering. While significant progress has been made, butanol fermentation pathways remain inefficient. Titer and yields are low, and separation is costly. As a result, microbial butanol production is not cost-competitive with petroleum-derived butanol. Although commercially unproven, combining electrochemical and microbial production methods may offer a way to produce butanol from renewable sources.