Compounds called metal oxides are essential in the procedures that lower carbon dioxide (CO2) emissions. These procedures include hydrogen energy production, inert gas purification and recycling for solar panel manufacturing, thermochemical energy storage, and carbon capture, use, and storage (CCUS).

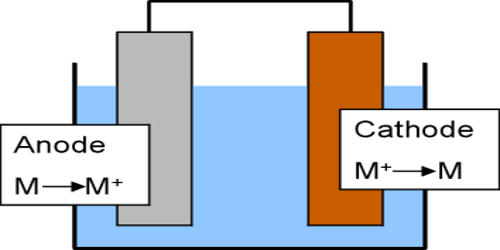

These procedures are based on redox reactions, which occur when metal oxides gain and lose electrons. But at the high temperatures needed for chemical synthesis, redox processes impair the performance of metal oxides.

With the development of a new materials design technique, a team led by Imperial College London is now able to create copper-based metal oxides that function better in high temperatures.

The technology is expected to help unleash even more power from current energy technologies that combat the climate catastrophe. It is already having an influence on argon recycling in solar panel manufacture on a global scale.

Senior author Dr. Qilei Song, of Imperial’s Department of Chemical Engineering, said:

“As the world transitions to net zero, we need more innovative industrial processes for decarbonisation. To enhance energy security, we must diversify the electricity supply, from renewable energy generation and storage to clean use of fossil fuels with CCUS technologies. Our improved metal oxides hold great potential for use in the energy processes that are helping us reach net zero.”

The paper is published in Nature Communications.

Unpicking a process

Metal oxides are key players in a relatively new process called chemical looping combustion (CLC).

As the world transitions to net zero, we need more innovative industrial processes for decarbonisation. To enhance energy security, we must diversify the electricity supply, from renewable energy generation and storage to clean use of fossil fuels with CCUS technologies. Our improved metal oxides hold great potential for use in the energy processes that are helping us reach net zero.

Dr. Qilei Song

In CLC, an alternate method of burning fossil fuels, oxygen from the air is transported by metal oxides, such as copper oxides, to react with the fuel. In the process, CO2 and steam are created, and the steam is condensed to effectively catch the CO2 and stop it from exiting the atmosphere.

CLC, which is already utilized in the EU, the USA, and China, enables people to use fossil fuels more sustainably by capturing the CO2 that is created.

However, a major problem that has prevented CLC from being used on a larger scale is metal oxides’ inability to continue performing well in terms of releasing oxygen even after going through numerous redox cycles at high temperatures.

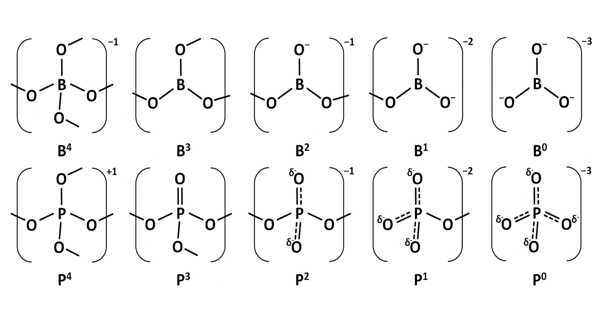

The researchers reasoned that the precursor chemistry of metal oxides was poorly known, which constrained their rational design, thus to address the issue they looked at the underlying structures of the metal oxides utilized in CLC.

Co-lead author Michael High, PhD candidate at Imperial’s Department of Chemical Engineering, said:

“To solve the question of how metal oxides maintain their performance, we looked to the basics of the chemical processes involved in CLC. This is a key example of combining fundamental research and smart design to produce a strategy that’s applicable to a wide range of engineering processes.”

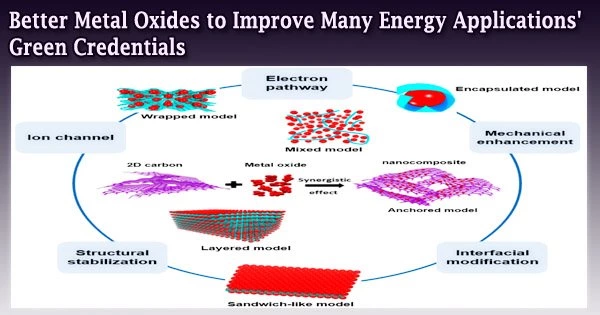

They developed the metal oxide structure using an alternate method from a well-known precursor made of layered double hydroxides (LDHs) of copper, magnesium, and aluminum.

Researchers discovered they could create metal oxides that could still function properly under very high temperatures by modifying the chemistry of LDH precursors. They did this by running the oxides through 100 chemical cycles over the course of 65 hours in a fluidized bed reactor, a type of reactor that is frequently employed.

Metal oxides made in this manner are more heat-resistant, allowing for greater power to be extracted from the purification and recycling of inert gases like argon for the production of solar panels, the capture and storage of carbon, chemical energy storage, and the production of clean hydrogen.

The researchers increased the synthesis of metal oxides for use in fluidized bed reactors to demonstrate this. They discovered that producing these materials is straightforward and easily scaled up using current industrial manufacturing techniques.

Senior author Professor Paul Fennell, also of the Department of Chemical Engineering, said:

“The world must reach net zero carbon emissions by 2050. Renewable energies are developing rapidly, but in the short term we need to develop cost-effective carbon capture technologies that can be applied to decarbonise the industry. Our work will help solve this global challenge.”

The researchers will also investigate the materials’ long-term stability during the burning of various fuels, look at fresh uses for thermochemical energy storage, and broaden the applicability to other metal oxide systems for thermochemical redox cycles clean hydrogen production.

This research was funded by Engineering and Physical Sciences Research Council (EPSRC), part of the UKRI, European Research Council, China Scholarship Council, and the National Science Foundation for Distinguished Young Scholars of China.