Researchers from Drexel University’s College of Engineering are putting a new spin on an old tactic for boosting the durability of concrete in the hopes of building structures that can heal cracks. Since the first masons mixed horsehair into their mud, fiber reinforcement has been used. However, the Drexel team is taking this technology a step further by transforming reinforcing fibers into a living tissue system that transports concrete-healing bacteria to the site of cracks to fix the damage.

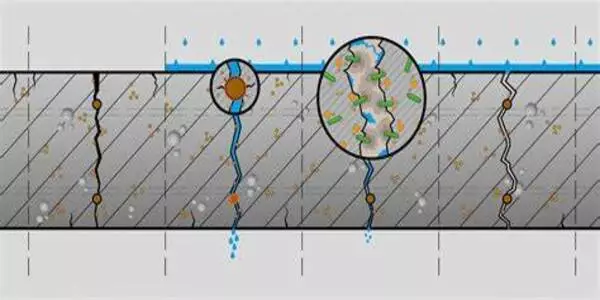

Drexel’s “BioFiber” is a polymer fiber wrapped in a bacteria-laden hydrogel and a protective, damage-responsive shell, as published in the journal Construction and Building Materials. According to the researchers, a grid of BioFibers placed within a concrete structure can improve its durability, limit crack growth, and enable self-healing.

“This is an exciting development for the ongoing efforts to improve building materials using inspiration from nature,” said Amir Farnam, Ph.D., an associate professor in the College of Engineering and project leader.

“We are seeing every day that our ageing concrete structures are experiencing damage which lowers their functional life and requires critical repairs that are costly. Imagine, they can heal themselves? In our skin, our tissue does it naturally through a multilayer fibrous structure infused with our self-healing fluid – blood. These biofibers mimic this concept and use stone-making bacteria to create damage-responsive living self-healing concrete.”

We are seeing every day that our ageing concrete structures are experiencing damage which lowers their functional life and requires critical repairs that are costly. Imagine, they can heal themselves? In our skin, our tissue does it naturally through a multilayer fibrous structure infused with our self-healing fluid – blood.

Amir Farnam

Increasing the lifespan of concrete is not just beneficial to the construction industry; it has also become a goal for countries throughout the world seeking to minimize greenhouse gas emissions. The process of producing concrete materials (burning a mixture of minerals like limestone, clay, or shale at temperatures above 2,000 degrees Fahrenheit) accounts for 8% of worldwide greenhouse gas emissions.

Concrete constructions, depending on their surroundings, can decay in as little as 50 years. Concrete is the most utilized and in-demand building material in the world, thanks to replacements and rising demand for new construction.

Producing concrete that can last longer would be a big step in reducing its contribution to global warming, not to mention reducing the long-term cost of infrastructure repairs, which is why the U.S. Department of Energy has recently launched efforts focused on improving it.

Over the last decade, Drexel has led the way in looking at how to improve concrete’s sustainability and durability, and Farnam’s lab is part of a team participating in a Department of Defense effort to fortify its aging structures.

“For several years, the concept of bio-self-healing cementitious composites has been nurtured within the Advanced Infrastructure Materials Lab,” said Mohammad Houshmand, the primary author of the study and a doctorate candidate in Farnam’s lab. “The BioFiber project is a collaborative, multidisciplinary effort that brings together expertise from civil engineering, biology, chemistry, and materials science.” The major goal is to create new standards at the confluence of these varied fields by pioneering the creation of a multifunctional self-healing BioFiber technology.”

The team’s approach in creating BioFibers was inspired by skin tissue’s self-healing capability and vasculature system’s role in helping organisms heal their own wounds. And it uses a biological technique they developed to enable self-repairing in concrete infrastructure with the help of biomineralizing bacteria.

The group identified a strain of Lysinibacillus sphaericus bacteria as a bio-healing agent for the fiber in collaboration with research teams led by Caroline Schauer, PhD, the Margaret C. Burns Chair in Engineering, Christopher Sales, PhD, an associate professor, and Ahmad Najafi, PhD, an assistant professor, all from the College of Engineering. The resilient bacteria, which is commonly found in soil, has the ability to drive a biological process known as microbial induced calcium carbonate precipitation, which results in the formation of a stone-like material that can solidify and harden into a patch for exposed cracks in concrete.

When induced to produce an endospore, bacteria can survive the extreme conditions inside concrete, remaining dormant until activated.

“One of the amazing things about this research is how everyone comes at the problem from their different expertise and the solutions to creating novel BioFibers are so much stronger because of that,” Schauer said. “Selecting the right combination of bacteria, hydrogel and polymer coating was central to this research and to the functionality of BioFiber. Drawing inspiration from nature is one thing, but translating that into an application comprised of biological ingredients that can all coexist in a functional structure is quite an undertaking — one that required a multifaced team of experts to successfully achieve.”

To assemble the BioFiber, the team started with a polymer fiber core capable of stabilizing and supporting concrete structures. It coated the fiber with a layer of endospore-laden hydrogel and encased the entire assembly with a damage-responsive polymer shell, like skin tissues. The entire assembly is a little over half a millimeter thick.

The BioFiber functions as a reinforcing support agent when placed in a grid throughout the concrete when it is poured. However, its actual abilities are exposed only when a breach in the concrete is large enough to pierce the fiber’s outer polymer shell.

As water seeps into the crack and finally reaches the BioFiber, the hydrogel expands and pushes its way out of the shell and up toward the fissure’s surface. The bacteria are activated from their endospore form in the presence of a carbon and nutrient source in the concrete while this is happening. The bacteria make calcium carbonate when they react with the calcium in the concrete, which works as a cementing ingredient to cover the crack all the way to the surface.

The healing time is ultimately determined by the size of the fracture and the activity of the bacteria – a mechanism that the team is now investigating – but early signs indicate that the bacterium could complete its work in as little as one to two days.

“While there is much work to be done in examining the kinetics of self-repair, our findings suggest that this is a viable method for arresting formation, stabilizing and repairing cracks without external intervention,” Farnam went on to say. “This means that BioFiber could one day be used to make a ‘living’ concrete infrastructure and extend its life, preventing the need for costly repairs or replacements.”