Brief history of the plant:

Fresh Foods Ltd. Is an 100% export oriented shrimps & fish processing industry, is established in the year 1994. The company is playing a leading role in exporting of quality frozen shrimps in the international arena. Above all this company is operating its business very successfully in the international market, contributing a vital role for boosting up the national economy. For better performance & to ensure quality products for it’s consumer this company is committed to implement HACCP programme. This company is tidy in his business-fair business policy is the result of its continuous success. It’s 3(three) years history of business have developed the idea/viewpoint the “the world is it’s market”. To well up the current demand of international community, the modification has been carried out in the factory under supervision of foreign expert.

Realization of the HACCP utility:

The hazard analysis critical control point (HACCP) concept is the system to ensure food safety to the consumer. In the past producer have required a positive approach of using GMP/GHP for producing food in a hygienic manner and by inspection of finished product.

It is now realised that inspection of finished products gives a poor control over the safety of Foods. On the other hand HACCP principles is a preventive safety approach, which improves the quality control of the process and a management tool provides the best control over the safety of products, giving an assurance that it will meet the importing countries requirements and promotes better use of resources and more timely response to the problem and in the end will save work and money as less product will be out of specification and there will be fewer claims and price reduction or re-calls.

Commitment Of HACCP Implementation

We are fully aware about the responsibilities of HACCP implementation program, which has been adopted by WHO in Geneva in the year of 1995. The principles of hazard analysis critical control points are scientific and educational tool, which provides the best control over the safety of the product than the previous end of the product testing system or a complex system such as the ISO 9000 series. Hence it has been designed as a safe guard for the product to sell in the international market. So, the management must have commitment to implement the essential program in our industry.

Therefore, I, being an owner of this company and has obtained education from home and abroad in fish processing, is committed to implement the HACCP program in my industry which, I think will be a mile stone in reaching the respective goal

Quality Policy

The company policy of M/s. Fresh Foods Ltd., is to ensure and sustainability of quality and safety of the products. This company always consider the buyers requirements and as well as buying locally requirements. To satisfy our buyers we are processing very fresh sea foods. We are maintaining our products quality as per US FDA CFR 123 and HACCP regulation, E.U. Directives and countyFIQC regulation.

Description of Plant

Location:

The factory is situated at a very well communicated place on the road of Khulna Mongla Highway, Elaipur, East Rupsha, Khulna. The factory is built in a two-storied building. Ground floor consists of entrance area, landing room, purchase room, washing room, chill room, ice storage, peeling room, processing and freezing room, packing room, cold storage, export passage etc. First floor consists of modern and decorated office, well-equipped laboratory, packing material store, water reservoir tank etc. The factory is well designed and constructed to maintain high standard of hygiene and prevent source of contamination. The surrounding are of the factory is free from contamination from nearby activities.

Main Entrance:

Our main entrance is well equipped with natural tiles and luxurious synthetic paint, which is dust and waterproof. We have three sub-entrances under the main entrance. One sub-entrance is for the officers and distinguishes person and another two for male and female’s access.

Walls:

The walls of the factory are made of hard surface non-absorbent materials (covered with tiles) up to ceiling, which is easily washable. The wall-to-wall joint is round.

Floor:

The floor of the factory is made of hard surface non-absorbent materials (covered with mosaic) and adequately drained facilities. The joint of floor to wall is round shape. The slope of the floor is 100X1 inch.

Doors:

Of all doors of receiving and processing entrance are made of self-closing type aluminum material so as to prevent pest entry. The door of chill room, packing room, cold store and export exit are made of hard surface and insulated materials.

Windows:

The windows are also made of Thai aluminum with glass, which is free from rust, easily cleanable and washable. All windows are fitted minimum one meter high above the floor.

Roof:

The ceilings are constructed of hard surface materials and painted with luxury synthetic paint, which is smooth, durable and easily washable. The joints of roof to wall are round

Drains:

The inner drains are of sufficient depth, rounded bottom, and easily cleanable channels from high to low risk area. The outer drains also are of the same type. All the drains are covered with removable, easily cleanable stainless steel plate. All the outlets are adequately guarded with nets to prevent the entry of rats, rodents and vermin’s.

Lighting:

Fluorescent tubes with sufficient illuminating power and safety covers are provided in everywhere. As required replacement of lights and cleaning of covers are usually done in between the shift.

Power supply:

For running the machinery, the plant has got electric supply from PDB (Power Development Board) of Bangladesh. Besides, there are two sets of stand by generators of 500KVA & 350 KVA for emergency requirements when PDB fails.

Aeration:

In order to provide comfortable working atmosphere, prevent excessive humidity/condensation, the plat has a ventilation system. The ventilation points are easily cleanable. Insets proof nets are set over there.

Water & ice supply:

The sources of water for all processing and other operating steps are from 650 ft deep. The water is pumped tot the aeration plant then to the overhead tank by the water treatment plant and subsequently distributed through non-corrosive metallic pipes through out the plant as shown in the pumping line map. The water is tested twice in a month in our in house laboratory.

As the company prefers to use flake ice instead of block ice, it has installed a flake ice machine of France origin, having capacity of 24 Mt per day. Water is chilled mechanically from where water is distributed at all processing steps.

Water Heater:

The plant also has got the facilities of hot water system for cleanliness and disinfecting of utensils and processing areas

Offal and waste disposal:

Waste disposal is the operation in any process offal and waste usually expected the mass of the product and require systems to hold them prior to remove, we use covered dustbin for the waste and clean the same as per cleaning schedule. All processing equipment’s have been made smooth, easily cleanable surfaces. Toxic metals not use.

Storage:

The plant is facilitated with frozen storage no.-l & 2 and ext.-2 frozen storage’s with capacity 600 Mts. and a chill storage of 15 Mts. Liquid ammonia is used as refrigerant and dial thermometers are placed at the places, from where the temperature can easily be recorded. The finished products are stored at least 6″ gap from the wall and 6″ from the floor thus allowing adequate air circulation, easy cleaning. The raw materials are stored temporarily in plastic tubs in the storage for a maximum period of 24 hrs.

Utensils:

We use maximum plastic and stainless steel utensils. We also use aluminum and stainless steel containers such as fish boxes and tubs and freezer trays and pans, which is rust proof and easy washable.

Chill store:

The shrimps are put into plastic container in sufficient ice and store temporarily in chill store at or below 5c for 24 hrs. The shrimp’s temperature at chill store does not exceed 5C°. Monitoring is done by QC staff.

Icing:

The source of water is deep tube well and after treated in ultraviolet ray’s water is used for flake ice production. Ice is properly done as ratio of shrimps and ice 1:1 and 1:3 depending of the quantity.

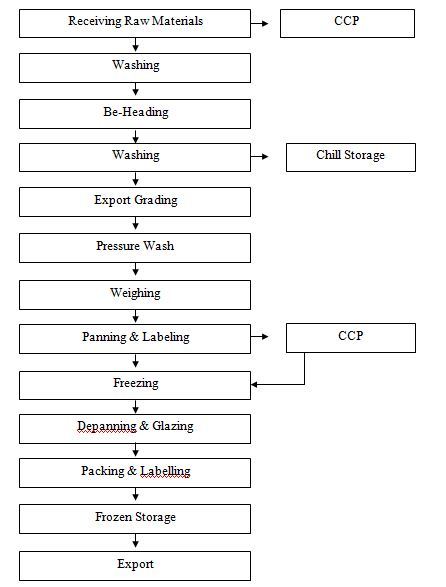

Beheading:

After receiving the head-on shrimps are beheaded and washed by pressurized chill running water. The water is chilled at temperature below 10C°.

Processing:

After beheading, the shrimps are processed for export grading. After grading, the shrimps are washed by pressurized water and then weighed as per buyers’ requirement. After weighing the shrimps are panned by workers, then the shrimps are loaded in the plate freezer. After loading, the shrimps are unloaded for packing, and therefore, after transferred to the frozen storage

Freezing:

The company has two contact plate freezers as follows:

1) Capacity Freezing time : 870 kg/ load for block and 480kgs/ load for IQF 2.3 hrs.

2) Capacity Freezing time : 1052 kg/ load for block and 580kgs/ load for IQF 2.3 hrs.

Metal detector:

Two metal detectors are in the packing area in the company, which senses the Fe-2.5 mm and Non Fe-3.0-mm accordingly. Before starting of work metal detector is checked by Fe and Non Fe test pads by QC personnel. QC personnel checked the efficiency of metal detector one after 30 minutes regularly during production and keeps record. If any discrepancy is noticed, inform to higher authority/foreman and take corrective action

| Construction and Equipment Facilities: Constructional: Landing Receiving Room Receiving entrance Washing room Beheading room Beheading entrance Chill Storage Processing Room Ante room Blast Freezer

|

22’x59′ 40′ X43.6′ 5.6’X 10′ 10 ‘ X24.6′ 22′ X70′ 5’X9.5′ 25.6’X 19′ 70.6’X 39′ 24’X19′ 18’XIO’ 22’X33′

|

| IQF room Peeling Room Frozen Storage -1 Frozen Storage- 2 Frozen Storage-3 | 94′.4″X34 10″ 63.5’X 35′ 26.6’X37.6′ 24.8’X37.0′ 24. 8’X37.0′ |

| Ice Storage Office Room Machine Room Overhead Tank Chill Water Tank Q.C. Laboratory Air Aeration Tank with ShowerTower

| 16’X19′ 16’X14′ 51’X24′-6′ ll’X10.5’X8′ 13’X10’X5′-6″X2 13’X 30.3’And 4.9’X 10′ 20’X30.3’ And 4.9’X2

|

| Male : Entrance Rest Room Dress Change Room Main Entrance Room

| 5.6″X10.6′ 12’X10′ 111.9×10.6′ 17.6×10.6′

|

| Female: Entrance Rest Room Dress Change Room | 3.3 x 10.6′ 15.6 x 10.6 13.Ox 10.6′ |

| Equipment: Plate Freezer Generator Compressor- Unit Coolers Pump For Cooling Condenser Control Pannel Board Ammonia Receiver Water Treatment Plant | 2 Nos. l’: Nos. (J) :KC-31,2Nos. (II).-KC-42, 1 No. (III) Metalex-42, 3 Nos. (IV) Metalex-4.00, 1 No. (V) KC-7.2, 1 No. (VI) KC-2.00, 1 No. (VII) Grasso – 7.2, 4 Nos. : 8 Nos. 6 Nos. 2 Nos. 2 Nos. 1 No. |

In addition, washing tubs made of stainless steel and plastic, plastic perforated bowls and processing and grading tables of stainless steel structure are also used.

1. Flake Ice Unit-France, 12 Tons Capacity Per Day -2Nos.

2. Laboratory for Regular Quality Check.

3. Water Chiller Capacity( 30,000) Liter/Hr.

4. Refer Van for Carrying Raw & Processed Shrimps – 2 Nos:

(I) Ashok Leyland, India – Capacity 15 Tons.

(II) Hcno, Japan – Capacity 15 Tons.

5. Ultra Violet set – 4 Nos. (Made in India)

6. Insect Killerat All Entrajicesand Processing Room Madein Japan

7. Steam Boiler 2 sets P/Hr -500Kgs(MadeinB3}

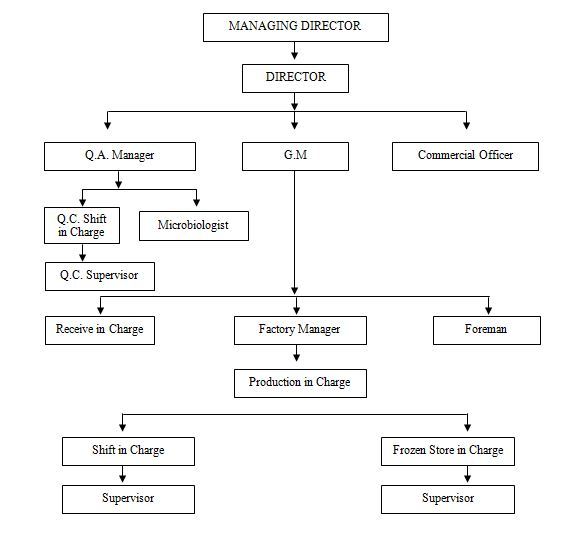

ORGANISATION CHART

Managing director:

He is the owner of the company and chief of the organization. He looks the over all staff administration, finance, correspondences with the foreign buyers and negotiate for any discrepancy of the product in the foreign market. He correspondence with the international agencies to develop the product through new technology. He receives the consumer complaint and reviews it with the director and Q. A. Manager; He reviews the overall HACCP plan with directors, M, production manager, Q. A. Manager, receive-in-charge and foreman.

Director:

Responsible to managing director. He is also responsible for coordinating to all sections i. e. production, Quality Control, security & admin. Engineering & accounts. He makes liaison with the company directors. He is directly responsible for public relation on behalf of the company. He re-views the HACCP. Plan with the HACCP team members. He is an M. Sc. And also obtained HACCP training under NFI-SGS HACCP training programme. He is empowered to spend up to take five Lac for HACCP implementation at a time.

G.M:

He is the key person of the production line. Responsible for day to day operation of the plant and directing production and any new process or procedures for the facility for the development of the product. He reviews the HACCP plan with director, q. a. Manager; receive in charge and foreman. He is responsible to the director for his work.

Q.A. Manager

He is the key person for producing of safe food in the facility. He is responsible for quality check at different operational steps, such as receiving of raw material, de-heading system, washing & grading, weighing & panning, freezing & packing and storage & export. Checking of SOP and SSOP, whether are in place or not, training of all concerned with quality assurance (e.g. supplier worker, supervisor). He is also responsible for re-call of the product due to consumer complaint or internal verification. He reviews the HACCP plan with director, G.M. receive in charge and foreman. He is responsible to the director for his work.

Production in charge:

Responsible for all type of product processed in the factory and sanitation operation. He looks the production line and implements any new system according to the direction of factory manager. He is responsible to G.M and Factory Manager for his work.

Shift in charge:

Responsible for day-to-day operation at processing line.

Frozen store in charge:

Responsible for frozen store management and adopting FIFO system in frozen store. He is also responsible for sorting the finish product at the time of shipment. He is responsible to his work to the G.M.

Receive in charge:

Responsible for purchasing all types of raw materials according to SOP, reviews the HACCP plan with the HACCP team members. He is responsible to his work to G.M.

Commercial officer:

Responsible for handling the customers, procurement of packing materials and office stationeries. Deals Mali with works concerning export and effecting proper shipment. He is responsible to his work to the director.

Foreman:

Responsible for maintenance of equipments and construction of the facility thus to help the factory to run smoothly. He reviews the HACCP plan with the member of the HACCP team. He is responsible to his work to G.M.

Supervisors:

Main instruments for proper implementation of HACCP plan by duly performing duties disbursed to team by the executives.

HACCP TEAM

Name | Designation | Qualification | Experience | Position |

| 1. Md. Masudur Rahman | Director | B.Sc (Hons), M.Sc | Training on HACCP, organized by FAO, NFI and SGS (BD) | President |

| 2. Muhibbullah Al-Kafi | Q.A. Manager | B.Sc (Hons) in fisheries, M.Sc in fish technology | Training on HACCP, organized by FAO, NFI SGS (BD) and also training on from Fish Inspection and Quality Control Department. | Coordinator |

| 3. Md. Shafiqur Rahman | G.M | B.Sc (Fish processing Technology) | Training on HACCP, organized by FAO, NFI and SGS (BD | Member |

| 4. Md. Wahiduzzaman | A.F. Manager | I.Sc | Do | Member |

| 5. Md. Nazrul Islam | Foreman | Diploma | Do |

Training of the HACCP Team

Each members of the team has got sufficient working knowledge on HACCP Principles. Director, Q.A Manager, .G.M. and Production Incharge have taken specific training on HACCP from different training courses organised by FAO, NFI & SGS (Bangladesh) Ltd. Rest of the members have been trained up by in house informal training. Company has got numbers of printed materials on HACCP system. Every member has very easy access to those materials.

Product Description

A description of the finished product must be developed in order to prepare a systematic evaluation of the Hazard and also associated risk in specific food and its ingredients or components. Our product has been described as under:

Product: Sea Water Shrimp, Fresh Water Prawn and White Fish.

Form:

- Raw Fresh Block Frozen Black Tiger Headless Shell-on shrimps.

- Raw Fresh Block Frozen Fresh water Headless Shell-on shrimps.

- Raw Fresh Black Tiger Head-on Shell-on Semi IQF shrimps. ^

- Raw Fresh Black Tiger HLSO IQF shrimps.

- Raw Fresh Block Frozen Harina, Chaka, PUD, P&D and P&D,PUD Tail-on shrimps.

- Raw Fresh Block Frozen Sweet Water White Fishes Whole, Dressing & IQF.

- Raw Fresh Water HLSO IQF shrimps.

- Raw Fresh BT or FW Cooked HLSO IQF shrimps.

- Raw Fresh BT or FW Cooked PDTO or P&D IQF shrimps.

- Raw Fresh BT or FW Blanched HLSO IQF shrimps.

- Raw Fresh BT or FW Blanched PDTO or P&D IQF shrimps.

- Raw Fresh BT/FW Skewer PDTO or P&D Semi IQF shrimps.

- Raw Fresh BT/FW Butterfly PDTO or PDTO IQF shrimps.

- Raw Fresh BT/FW Easy Peel HLSO IQF shrimps.

Packing: 6X4 Lbs.. 6×2 Kgs, 1.5 Kgs, 6×0.8 Kgs, 10×1 Kgs (Including 10-20% glaze for IQF or as per buyer requirements).

Brand : Sea pride

Storage : 18°c or below

Distribution : Block Frozen and IQF as consumer pack.

Ingredients : Shrimp & Water

Shelf life: : 18 months at -18°c or below

Type of product : Low risk type (Raw Block Frozen & IQF) &

High risk type (Cook IQF)

Consumer instruction : To be consumed only after cook

Intended Use

The company is producing raw frozen shrimps and white fishes for export to Europe, America, Far East and seeking other markets throughout the world. The frozen products, particularly raw block frozen shrimps are normally reprocessed by the processors in the 3rting countries. But IQF products are directly sold to the consumers in the super

Sanitation Standard Operation Procedure (SSOPS)

Sanitation is the key step in the fish processing plant. If sanitation programme is not well implemented in the processing plant, then it is possible to contaminate the product, food contact surfaces and food packaging materials in any moment. The SSOP of the company are made in considering the USFDA HACCP guide line, specially considering the 8 key sanitation points. These are-

Pest Control

The pest control system of the company are as follows:

- The primary defense against infestation is general environmental hygiene ensuring no equipment or food waste is allowed to accumulate around the factory.

- As well, regular hosing of the external factory environment is carried out. So, the factory premises are free of harborage areas.

- Rodenticides are deployed externally around the process areas and internally in all amenities, offices, dry stores, compressors and machine rooms.

- All ventilators, exhaust fans, out let of the drains are well netted.

- A set of electric devices insect killer is placed at the entrance of processing room, landing room, at the export door, receive room, de-heading areas and dress changing room. When any insect populations comes to notice, then approved insecticide is used.

- Appropriate traps for rats are used at different places (possible routs). Such as food packaging material storage, out let of the drains, entrance of way, export door, waste disposal ways, machine room and the waste storage.

- One quality control staff monitor it and keeps records and when any discrepancy comes to notice, than he will give information to his higher authority

Structure and layout:

Factory building is a two storied building. Ground floor consists entrance, dressing room, toilets, processing room, purchase room, chill room, cold storage, packing room, machine room, flack ice room, etc. – .

1st floor consists – laboratory, dry store, office, chill water tank, staff quarter, guest room etc.

The factory ground condition are so designed that there is no chance of contamination through wind drafts, personnel foot traffic, adherence to personnel clothing, flooding etc.

The building is easily accessible to all its parts for the easy of cleaning and sanitizing.

Floors, walls, ceilings of all the rooms (including rest room and employee break rooms) are hard surfaced non-absorbent waterproof, smooth, light coloured and easily cleanable and sanitizable.

Doors are sufficiently wide and of self closing type. Windows are at 1 meter above the floor and easily washable. The wall to wall, wall lo floor, wall to ceiling joints are round.

There is no way of product contamination and adulteration in the facility. The facility has sufficient separation between different activities such as their processing. Packaging and handling of food products. There is sufficient separation between raw product and finished product, so no chance of cross contamination. The equipments and utensils are so designed and constructed that it is easily cleanable, sanitizable and inspection able. Hence, there is no chance of product contamination or adulteration through the equipment’s and utensils one quality control personal monitor it daily and keeps record and gives information to any discrepancy to his higher authority.

Maintenance:

The roofs, ceiling, walls, floors, light fixtures, equipments and utensils of the facility are maintained at a high level, leakey roof, crackes or depressions in the floor and walls, or unprotected glass lighting fixtures are not permitted in the facility. It will be used after good repairing. Rusted or pitted tables, trays, and trolleys arc not used in the facility without good repairing.

Lightings arc arranged adequate in the areas of food handling, processing, storing, packing and sanitation that the operation is to be performed in a sanitation and wholesome manner.

All equipments and utensils such as product contact surfaces are kept in good repair. Packaging materials are adequately kept covered with polythine in the store. Hence there is not possibility of contamination of the packaging materials through condensation.

One quality control personnel monitor the areas, equipments and utensils, which comes in contact of food, food packaging materials daiN . • He keeps record and gives information to his higher authority when any discrepancy comes in to notice.

Cleaning and sanitation:

A high degree level of cleaning and sanitizing programme are operated in the facility. All product contact surfaces and non-product contact surfaces are properly cleaned and sanitized in every day through two stage cleaning system, the system is as follows:

Stage-1 cleaning:

1. Remove all gross debris by brushing, scraping, or flushing away with water, where necessary dismantle equipment for cleaning.

2. Wash all surfaces with detergent in hot water, soaking and/ or scrubbing where necessary. A general neutral detergent should be used diluted to the manufacturer’s recommendation concentration.

3. Rinse all detergent solution away with clear cold water.

Stage -2 Sanitizing:

1. Prepare a sanitizing solution of 100 PPM. It is better to use cold water.

2. Bench all surfaces with the solution, or small items may be soaked in tub of solution.

3. Minimum solution contact time is 20 minutes should the equipment or work area be needed for use immediately there after, then all sanitizing solution can be Hushed away with clean cold water as soon as the contact time is completed.

Good house keeping of all areas are operated in the facility. All employees are must taken care for the venation of cross contamination or adulteration to product through in advertent of touching of prod-or product contact surfaces with wash water, detergent, sanitizes etc during production.

A schedule of cleaning and sanitizing is given below:

1. Before starting of work; all product contact surfaces and non product contact surfaces are cleaned with potable cold water.

2. Within the period of work (middle of two period): all dist and debris are removed from the product contact surfaces and cleaned with potable cold water.

3. After ending of work: all dirt and debris are removed from the product contact surfaces then it is cleaned with detergent through brushing, rinse with hot and cold water potable water and sanitized wi th 50-100 PPM chlorinated water at least 20 minutes contact time. Rinse with cold potable water and put on the identified places for drying. All non product contact surfaces are cleaned with potable cold water.

One quality control staff monitor it and keeps records and when any discrepancy comes to notice, than he will give information to his higher authority.

Personal Hygiene & Personals

A high degree of personal compliance is maintained in the facility. All persons including occasional works, take necessary precautions at the time of processing or handling of Foods are as follows:

i. Before staring of work, after each absence from the workstation and at any other time when the hands may be come soiled or contaminated they wash their hands with soap and sanitize in the hand dipping.

ii. The cleaning and sanitizing operation is monitored and recorded by quality control staff in everyday and give information to his higher authority when any deviation comes to notice. Al 1 Jewellery, Nail Polish or false Nails, chemicals and medicates, strong perfume’ aftershave and make-up are not allowed in the facility.

iii. No person is not permitted to work in the facility, who is affected by disease in a communicable from or while a carrier of such disease or while affected with boils, sores, infected would or other abnormal source of microbiological contamination.

iv. Smoking, eating and drinking in the processing area are not allowed.

v. Staff engaged in processing shall wash their hands after every 30 minuies

vi. Clean and sanitize gloves are used. Dirty or non sanitary gloves are prohibited.

vii. All persons will have to wear or outer garments, hair nets, caps, gumbots and masks at the time of processing or handling of Foods.

viii. Storms street cloths or other personal belongings, eatingfood or drinking nor usmgtobacco in any form in areas where food are exposed or packaging materials washing of equipments and utensils or in processing area are strictly prohibited.

ix. Hand washing basins with auto sensor tap/fool drive tape and all other facilities are placed at all washing points chlorinated water, toilet soaps, disposable tissue role are also provided at relevant points in the facility and all person will have to use this before starting the processing or handling the Foods.

x. hygiene passage before entrance room equipped with ozone airsanitizer valve for personal hygiene is provided. –

xi. Five separator coloured outer garments, haj’r nets, caps, gumbots. for staffs, graders, process workers, cold store & purchase section is provided with the materials which is easy to clean.

xii. Health cards are provide for all workers in the facility. “Marie stops Clinic” is appointed for personal health monitoring in every month in the facility.

xiii. For washing all protective clothing’s a laundry outside the factory is contacted regularly.

A quality control stall” monitor every day and keep records and give information to his higher authority when any discrepancy comes to notice.

Rest Rooms

The facility have provided eleven toilets (5 toilets for male and 6 toilets for female) for the production related personals. These are constructed with well ventilation; floor wall and ceiling with light colour, smooth, washable, tiles. The filtering steps are duly provided with all facilities there. Cleaning is done as per schedule, times a day. Hand washing and hand sanitizing facilities are provided adjacent to the toilets. Such as soap toilet paper, chlorine water etc. One quality control staff-monitor it before starting of work and within the middle of work and keep records and give in formation to his higher authority when any discrepancy comes to notice. Every body will have to wash & sanitize their hands after every return from the toilet.

Water and ice:

Water supply and treatment

1. Water supply: The factory have own deep tube-well supply water which is free from filth, deleterious harmful chemicals, heavy metals, bacteria, virus etc. This water is pumped to the Aeration plant & than to the overhead tank by the water treatment plant for circulation of different points. About 70,000 liters of water is used daily in the facility from the overhead tank, water is re-circulated to the following areas:

- Amenities

- Factory

- Ice plant/compressor/generator.

2. Water treatment; The facility have set up a water treatment system that provides the water quality as PDA &EU standard. Prevention of cross- connection of plumbing back siphon age or back flow from a contaminated source to the supply system have been taken in the facility. Water is tested in the own Iaboratory4timesfti a month. The test reports are recorded and monitored

ICE:

Ice is manufactured with properly treated potable water. The facility is provided for flake ice plant. The ice is free from all source of contamination, such as filth external materials bacteria, virus, Ice is taste & times-n month in our own laboratory. The ice is stores are impervious, cleanable and sanitizable. The ice is holding on plastic dunnage. The handling equipment of ice is cleanable and sanitizable and appropriate for food contact surfaces. Used ice is not re used to the food product in the facility. The water supply system is monitored every day and keep record and give in formation to the higher authority when any discrepancy comes to notice by a quality control staff.

Chemicals:

Chemicals are used in the facility according to the manufacture instructions. The facility use the PDA & ED approved chemicals. The facility use the following chemicals:

| NAME BLEACHING POWDER CA (OCL) CL- 0.2% W/W 5-BIO-ALATHRINE AEROSOL -ACI LTD. 0.12% W/W PERMATHRINE | FUNCTION SANITIZER -INSECTICIDE |

Solid lifebuoy soap & Liquid soap -LAW LIVER BROTHERS-DETERGENT.

LTD.

Luny-Rat-Ciba-Geigy – Rodenticede.

Sodium Hypochlorite-Comm. Grade – Sanitiser

Sodium Chloride-Modhu Mali Salt Ltd. – Ice Making.

Surf excel, Wheel powder, Vim & Harpic – Germicide &

All chemicals are properly labeled and stored in a safe manner which is away from food handling or processing or food packaging materials use of chemicals are monitored and recorded by a quality control staff.

Ventilation:

Prevention of condensation, which is the cause of filth bacteria or other contaminates to adulterate ad products through drippage as exposed food,” processing equipments or packaging materials, the liability have been provided sufficient ventilation system, to prevent foul ordur which is the source of terial activity, the facility have been provided sufficient exhaust fans in the different places in the liability. One quality control staff monitor dat I y keep record when any discrepancy comes topic, then he gives the information to his higher authority.

Disposal:

equate drainage system have been provided in the facility for bodily waste, gurry, process water For the prevention of fecal and human disease organism, which is possibly to contaminate the d product through splash and foot traffic. The out side of the drains are connected and vented to werage system for processing waste. Adequate waste bin is placed at the appropriate location iugh the plant and removed in every two hrs intervel at the time of processing. The waste bin and the storage are covered, have no possibility of attraction of rodents insects and other vermins. One city control staff monitor the activity and keep record in every day and when any discrepancy ics to notice, he gives information to his higher authority.

Standard Operating Procedure (SOPS)

Fresh Foods Ltd. Maintains some standards at its every operational steps, SOP has a vital role for the production of safe food in the facility. The facilities have been operated a standard operating procedure (SOP) to produce safe food for the consumer. The operational procedures are as follows:

Raw material:

The shrimps used in processing of the product shall be clean and wholesome and of such quality that the finished product shall comply with the provisions and conditions specified. Raw materials are collected from the different suppliers, culturist and it is transported from the catching center to the factory by our own insulated van. All raw materials must be pre-cooled after harvesting and without pre-cooled raw materials are not accepted in the facility. The standard of rawmaterials are as follows:

Shell-on products:

1. The raw materials shall be clean, whole some and fresh and shall not show any visible signs of spoilage.

2. The colour of the raw materials shall be typical of freshly caught. The meat shall be firm and shall have the typical odor of freshly caught.

3. The materials shall be free from any discoloration and off odorous.

4. All shrimps/prawn must be head on.

5. Decomposed dehydrated, dirties, black spotted, discolored shrimps are not accepted

6. Maximum 1 % soft shell shrimps are accepted.

7. Raw materials must be properly iced Raw materials temp. Should be below 5°c.

8. Raw materials must be free from any foreign materials and any lubricant

9. Supplier’s certificate and proper tag must be with every lot and basket

10. Mixed fishes (shrimps & other fish) baskets are not received SOP has a vital note for the production of safe food in the facility. The facility have been operated a standard operating procedure (SOP) to produce safe food for the consumer. The operational procedures are as follows

Shell-off products:

1. Discolor 2%, soft shell 3%, de-hydration (not in the meat) 2%, black spot (not in the meat) 2% shrimps arc accepted.

2. Headless and dirtious shrimps are not accepted

3. Supplier certificate and proper tag must be with every lot and basket.

4. Shrimp temperature must be below 5°c.

White fishes:

1. The raw materials shall be clean, whole some and fresh and shall not show any visible signs of spoilage.

2. The colour of the raw materials shall be typical of freshly caught. The meat shall be firm and shall have the typical odor of freshly caught

3. The materials shall be free from any discoloration and off odorous.

4. Raw materials must be properly iced. Raw materials temp. Should be below 5°c.

5. Raw materials must be free from any foreign materials and any lubricant.

6. Supplier certificate must be with every lot.

Receive-in-charge monitor the receiving steps and send the report to the quality control dept. Quality control dept. Keep the record and give in formation to the higher authority, when any deviation comes to notice.

Short storage:

The company uses its chill storage for storing raw shrimps for a maximum of 24 hrs. at less than 5° C user well icing condition in done by quality control supervisor.

Purchase specifications:

Bthoso Shrimps

| No. of shrimps per kg. | Wt. Of each shrimps |

| 20 30 44 66 100 | 50 Gm. 33.33 Gm. 22.12 Gm. 15.15 Cm. 10 Gm. |

| Fwhoso Prawns | Wt. Of each shrimps |

| 5 10 20 30 50 60 | 200 Gm. lOOGm. 50 Gm. 33.33Gm. 20 Gm. 16.66Gm. |

| Har1na Or Chaka Hoso Shrimps Per Lb |

|

| Average | 10 G or Less. |

The other parameters of the raw materials under receive must not cross the following limits for the defects given below: –

Decomposition None

Dehydration None

Black Spot 2% By Count

Damaged Piece % By Wt.

Soft Shell 2%By Wt.

Extraneous Material (Not Harmful) 0.3%ByWt.

Parasites None

Contaminated With Saw Dust,

Oil, Fuel, Chemicals None.

Temperature 0 To 5° C.

Monitored by receiving supervisor for every basket, and periodically checked by QC. Deptt

Water

Wafer is one of the most critical factors in making safe products, which will be safe to eat and will meet the required microbiological standards. The water supply should be checked for microbiological contamination at frequent intervals. Our source of water is installed 650,650&650ft deep tube well that is free from bacteria, harmful chemicals, heavy metals, filth and viruses etc. Water is treated by ultraviolet treatment plant is also provided on the initial point step of the supply. The facility maintain the WHO & EU water standard for the food processing. A high pressure system is available for washing down the premises; all water used for cleaning down should be chlorinated.

For primary wash – < 2 ppm

For panning & gla/.ing – < 1 ppm

For hand wash – < 20 ppm

For utensils wash – 50-100 ppm

For foot wash – 100 – 200 ppm

For floor wash – 100 – 200 ppm

We must meet the following water standard: –

pn 6.5-7.5

Chloride 200-280 MG/L

Electrical Conductivity 400uG/CMat20’C

Iron 50-lOOiG/L

Col i form Bacteria Nil l/100ml

E. Coli Nil OR < 1/100 ml

TPC or SPC 10at37°C/ml

100at22°C/ml

We test the quality of water in our own laboratory four times in a month. The water supply is mortared by a quality control staff He gives in formation to his higher authority when any discrepancy comes to notice.

ICE:

Ice is the very important factors at the processing industries. The facility have been provided a flake ice machine and ice is produced from potable water which is used in the facility for food processing. The ice standard is same as the water standard. It is tested in our own laboratory four times in a month. Ice is monitored by Microbiologist. Beside this local competent authority is also monitoring water and ice quality in every month as the monitoring plans

Process parameters:

Icing:

Icing is dependent on the storage time of the raw materials in deferent processing steps. Normally 1:1 or 1: ½ ratio of icing is followed.

There are three important factors related to the mechanisms that cause fish and shrimp prawn the whole some which affect the quality of the raw materials. These factors are time, temperature and cleanliness.

Time:

Time is being controlled in all steps of food processing. Raw materials should not be kept more than one day in the chill room. From receiving to before freezing, time is taken normally 1.00 hrs to 1.50 hrsbut food products are not more than 20 minutes kept in any processing steps.

The quality of the product can be made better, if the time between catch and process can be made shorter.

The following timing is strictly followed at every operating steps stated below:-

For Block products (Total 235 minutes) | For IQF products (Total 125 minutes) |

| Receiving – 20 minutes Washing – 2- 4 minutes Beheading – 20 minutes Grading – 20 minutes Pressure wash – 2 minutes Weighing – 2 minutes Panning – 3 minutes Plate freezing – 150 minutes Deplaning & glazing – 3 minutes Packing – 10 minutes | Receiving – 20 minutes Washing -2-4 minutes Beheading – 20 minutes Grading – 20 minutes Pressure wash – 2 minutes Peeling – 20 minutes IQF freezing – 30 minutes Packing – 10 minutes |

Temperature.

Autolysis on enzymic spoilage and bacterial action are both biological in nature. It is a characteristic of biological systems, the function of it depends on temperature. The lower the temperature the slower the enzymetic reaction in the fish. One of the most common methods of slowing down the rate of action of enzymes and bacteria is by reducing temperature in preservation methods such as chilling and freezing It is said that a reduction of 5°C halves the spoilage rate.

“Cold Chain” is strictly followed by controlling the temperature with limits as stated below:-

Receiving Room Temp. 21°C

Raw Materials ” 5°C

Water (1st Wash) ” 10°C

Chill Storage ” <5°C

Raw Materials ” <5° C

Be-headingand peeling room ” 21° C

Processing Room ” 21 ° C

Pressure Wash Chill Water ” 10°C

Temp, of Loading of freezer ” 6° C to 7° C

Unloading Temp. ” – 40°c

Core Temp of Block ” -20° or below

Glazing Water ” 2° C to 3°C

Ante Room ” 10° or below

Frozen Storage ” -18° C or below

The temperature is monitored and recorded by the Q.C. supervisor and he gives information to his higher authority when any discrepancy comes to notice.

Cleanness of Shrimps:

Bacteria are present just every where. They are found on the surface of the fish when it is caught, on the boxes and all the surfaces where it touch. We can reduces the load of bacteria by washing with clean water. Over 90% of bacteria can be washed from the surface offish using clean water. When we catch the fish first of all we should wash it with clean water. We maintain the following principles to handle the fish.

- Keeping the fish cool

- Keeping the fish undamaged

- Keeping the fish flesh clean

Chill water condition:

In every steps of processing chill water is ensured in the facility. Auto chiller is used for cooling water. The facility maintain chill water temp. <2° c to 1 0″ c in different steps of processing. Less than 5 PPM chlorine water is used in primary washing and other steps no chlorine water is used.

Hot water condition:

Hot water is ensured in the facility for washing of floors, product contact surfaces, utensils etc. The , temperature of hot water is maintained 65°c or above.

Grading procedures & standard:

Hand grading is provided in the facility. A team of 5 to 6 persons are allowed to work on each grading table. All of team are skilled and efficient. Out of them one has been selected as team leader whose main responsibility is to check the grade whether any deviation is occurred. Grading is dependent on buyers requirements.

Export grade:

The company normally follows the under stated grading procedure and the tolerance limits. But it is changed according to the buyer’s and seller’s contact.

For 4 Lbs. Block Package:

| Size | Total Pieces | Tolerance | Wt. of Each Shrimp | ||

Large | Small | |||||

| SWBTHLSO | 8/12 13/15 16/20 21/25 26/30 31/35 36/40 41/50 51/60 61/70 | 47 59 79 99 119 139 159 190 230 270 | 46-47 58-59 78-79 98-99 118-119 138-139 158-159 189-190 229-230 269-270 | 56.75 34.92 22.37 21.61 17.46 14.64 12.61 11.07 8.90 7.44 | 37.83 gm 30.26gm 22.7gm 18.16 gm 15.13 gm 12.97 gm 11.35 gm 09.08 gm 7.56 gm 6.48 gm | |

| FWHLSO | Special | 10 | 8-10 | |||

| U/5 | 20 | 18-20 | ||||

| 6/8 | 30 | 28-30 | ||||

For. BTHILSO / FWHLSO Packing: 1X10Kg (Bulk)

26/50 480 479-480 17.46 – 9.08g

Size | PCS/KG | Total | |

| SWBTHOSO | 8-12 13-15 16-40 21-25 26-30 31-40 41-50 51-60 | 12 15 20 25 30 40 50 60 | 12 15 20 25 30 40 50 60 |

However, grading is also done as per specification of buyer. Monitoring is done by grading supervisor and he keeps the record and gives information to his higher authority when any deviation comes to notice.

Weighing procedure & standard:

Weighing is done according to the specification. Therefore, weighing must be entrusted to a responsible person. Weighing is done is a normal balance. Normally the shell on shrimp is packed 4 Ibs, 2Kg , IKg, 0.9Kg, O.SKg, 1.8 kg or as per buyer choice.

Weight extra 2% for shell on and 5% for peeled should be allowed to prevent weight shortage. Semi 1QF is packed according to the buyer specification. Also white fishes are packed according to the importer’s specification. It is monitored and recorded by supervisor and given information to his higher authority when any discrepancy comes to notice.

Any leftover water should be removed from the plate of the balance before each weighing.

Panning (distribution of pieces):

After weighing the shrimps are dressed in the pans made of stainless steel. Shrimps are wrapped with polythene. On each pan grading tickets, brand name, shift code and license no. Is used. Pan is prepared according to the capacity of freeze.

It is “final processing of the shrimps”. The basis of panning is-

1. Try to prevent the fragile cephalothoraxes and tail fan from damage.

2. With a thorough glaze, prevent the shrimp from dehydration.

For arrangement, place each shrimp with the tail fan curled and the cephalothoraxes facing out so that a shrimp in the adjacent row hides the tail. To show more of the shrimp, lay it on its side.

Stand by condition:

Temperature:

When panning is completed cold potable water is poured over the raw pack to submerge the shrimp completely. Be extremely careful when pouring water because in sufficient water may cause cracks, breaks or black spots, reducing the market value noticeable. Temperature is maintained at or below 5°c by pouring ice in the pan.

Time:

Normally pans are kept 20 minutes on the stand by position. Panning is monitored and kept record by a supervisor.

Freezing parameters and control:

The freshness of the product which determines its value depends on the cooling system and time consumed from catching to completion of freezing. Therefore, the shorter the freezing time, the better the products quality will be.

The following method is used for plate freezer/contact freezer operation in the facility:

1. Put the freezing pan gently on the frosted shelf

2. Dry the plates.

3. Load blocks quickly lower plate first, upper last.

4. Close plates (no positive pressure)

5. Complete freezing cycle.

6. Cool plates to -40° c and freeze until the shrimp/fish temperature at the center of the block comes down to around -18″ c. The core temp. Is checked by digital thermocouple.

7. Open the plates.

8. Unload quickly

We use contact and air blast freezer which requires comparatively less time and it is evidently advantageous. We follow the following method for air blast freezer operation:

1. Cool-down the room temperature -18°c.

2. Putting the freezing pan/tray on the frosted rack.

3. Load the pan/tray quickly lower rack first, upper last.

4. Control the air stream properly.

5. Close the air blast door.

6. Complete the freezing cycle.

7. Cool room temperature to -25° c and keep 30 minutes so, that shrimps temperature at the center of the shrimps/fish comes down to around -18°c and rack the core temperature.

8. Open the air blast door.

9. Unload quickly. Ammonia is used in refrigerator.

Deplaning and glazing:

After completion of freezing, depanning is done very carefully and quickly so that the block does not break, and deform. If glazing is required, then it is done with chill potable water at <2°c. To make the block apperance attractive the total time set for this operation is maximum 25 minutes. The operation is run in ante room at <10″ c. Monitoring is done by storage supervisor

Packaging:

Packing should be done in the ante room which temp. Must be below 10° c. Regardless of the manufacturing method, water proof laminated /waxed paper is used as inner carton and the following markings go on the front & side :-

Front:

Brand, net contents, packer’s name, place & country, approval no., origin and farm raised Side : size, count, type and grade, product name, date of production, best use before, batch no. & lot no. Also “the products are produced under our approved HACCP plan” is written on the inner cartons.

Before packing shrimps block transferred through the metal detector and then packed in inner carons and 1QF products in poly bag transferred through the metal detector and it is placed in MC which is made of corrugated card board of sufficient thickness and of such a quality that they stand the stress and strain of transit, the master carton have a good binding and it bears the same information as on the inner carton. Unless otherwise specified, master cartons are generally packed 6×4 Lbs, 6×1.6 kg, Gxlkg, 10×1 kg, IXlOKg(Bulk). White fish packing type: 12×0.8 kg, 12×0.6kg, 12×0.7,16×0.6kg 20×0.3 kg, & 13×0.3kg etc. Total operating time at this step is maximum 20 minutes. Monitoring is done by storage supervisor.

Labeling:

a. Name of the food : the name of the product to be declared on the label. Shall be shrimp, prawn or fish provided that such leveling is customarily used in the country where the product to be sold.

b. Presentation : shrimp. Prawn & fish shall be presented as follows :

(i) Whole (ii) headless (iii) peeled (tail fans on) (iv) pieces & other presentations.

c. The nature of product shall appear on the label as raw, fresh, ready to cook.

d. The term quick frozen shall also appear on the label.

e. It the product is individually quick frozen then classification of the product also to be mentioned in the label

a. List of ingredients: a complete list of ingredients shall be declared when the product is packed.

b. Name & address : name & address of the manufacturer, packer, distributor, importer, exporter or vendor of the product shall be declared.

c. Net contents: the net contents shall be declared by weight in the system international.

d. Country of origin : the country of origin of the product shall be declared if its commission would mislead or received the consumer.

e. Lot identification : each container shall be permanently marked in code or in clear to identify the producing factory and the lot.

Frozen storage :

The master carton with the frozen products are stored in the frozen store at -18°C or below. The products are separated by type, size, grade and lot wise to make shipping easier. As frequent movements in and out of the storage room tend to raise the storage room temperature. Air cartains are provided at the door. The products to be stored lot-wise keeping min 1 – distance from one to another for easy air circulation. The facility ensure the FIFO system in the frozen store. Fluctuation of temperature should not be more than 2°c is permitted in the frozen store at the time of defrosting. For each type of product, separate frozen store is used for storage of the product. For the prevention of condensation in the ante-room, the facility have been provided sufficient unit cook and de-humidifies in the anti-room without packing products are stored in the frozen store is prohibited.

Storage-in-charge is monitored and kept record and given information to his higher authority when any deviation comes to notice.

Export:

The products are exported through Mongla seaport. The products are carried by own refrigerated van to the port for export, which takes about 25 minutes. Product temperature is maintained below -18°c up to the loading at the container.

Dry storage:

All packing materials are stored in a room with well ventilation, wall dunnage and floor dunnage along with shelves. Chemical are stored separately to avoid hazard.

For HLSO shrimps:

Decomposition None

Dehydration None

pH 6.5-7.5

Impurities

(Detached shrimp parts) None

Foreign matter Soft shell 3% max by wt.

Broken B2% max consisting

a. Any usually torn/broken shell

b. A break in the shell which allows air bubbles that are found on both sides of shrimp body and exceed 2 segments of shell

Loose shell Max 2% by wt.

A break in the shell which allows air bubbles that are found on one sides of shrimp body and exceed 2 segments of shell.

Scarred shell max. 3% by weight (for size of scars Vz cm.)

Melanosis 2% black spot/ring (by weight) on shell only.

Size uniformity Shrimps are of consistent size within the declared count

per pound as follows

40 count/Lb and larger <1.5 Uniformity ratio

41-75” <1.7

71-150” <2.0

-<150” <3.0

Method: Wt. Of 10 largest shrimp wt. Of 10 smallest shrimp taken from the entire sample block

Microbiological standard:

For setting its bacteriological standard offish & fish products (shrimps). The company is following the guidelines of FIQC, DOF, Khulna, which is as below:

SPC

The above parameters are tested in company’s own microbiological laboratory in the 1st floor and the analysis is conducted by the microbiologist.

Workmanship:

The products are processed carefully to have :-

a. Minimal level of neck meat shell not exceed the length of the 1 * pair of swimmerets from the head end

b. Uniform color,

c. Uniform glazing.

d. Tail firmly intact for tail-on product

e. For peeled tail-on product last part of swimmerets attached to the tail shall not exceed 5% by wt.

For Peeled Shrimps

Defect table is as below:-

Type of defects Max. tolerance

Black spot (Darkened areas which 2%

seriously affect appearance)

Cut torn or damaged (Cut & torn 3%

a break V2 of the shrimps thickness &

Damaged-shrimp crushed or unitilated so 3%

as to affect its appearance seriously

Pieces (a portion of a shrimp that contains 3%

less than 4 segments except when

count isour200/Lb)

Improperly peeled (Shell or pieces of

shell on the meat)

Incompletely defined (any black or dark 3%

vein should have been removed at

least up to the last segment next to tail i.e. telson

Except when count is our 80/lb 2%

Extranous material (not harmful, such as

heads, pert of heads, soft shell shrimp,

legs lose shell and antennae)

This operating step is monitored by quality control supervisor:

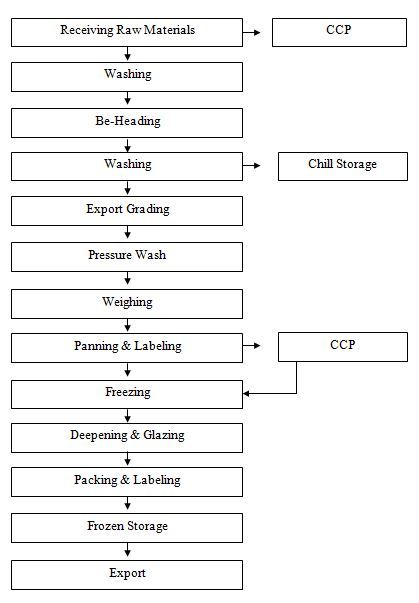

Process flow chart for BT Hilso Shrimps:

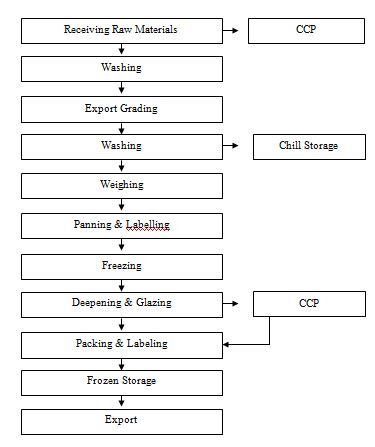

Process flow chart for BT HILSO Shrimps:

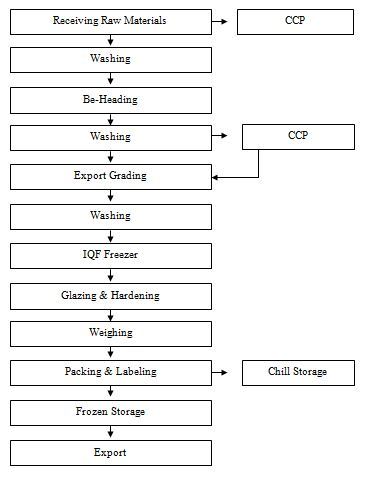

Process flow chart for BT HOSO IFQ Shrimps:

Process flow chart for BT HILSO Shrimps:

Procedure For Consumer Complaint

We have already develop a consumer complaint file for handling of complaints. All types of complaints should reach to our consumer complaint handling department in written through Managing Director. After receipt any kind of complain from our valued customer, it will be investigated the cause of complaint

Action is taken to correct the cause of the complaint, if it is a legitimate complaint and it is recorded on the complaint form. All of the consumer/complain form and memos are kept on the file in the Q. A. Manager office

Identification And Traceability

The company has recall procedure in case of out of control situation when the raw materials scrived is identified by a lot number, date of receipt of raw materials, details of origin, etc., from the shipment record. Finished products can be identified by product type, size, day [codes, batch number, and shift code. The type, size, day code, batch number etc. are given on enable traceability of the days production. The raw materials used for the days production be easily retrieved. The samples for the quality checks are also drawn from each lot as [per sampling plan. In case of details the code and batch number enable to ensure traceability the end product back to the raw materials used. The process criteria are maintained throughout the production, recorded in on line QC log and the packing register, which are

also useful in initiating recalls

Procedure For Control Of HACCP Plan

The HACCP Plan and the manual shall be authorized by the Managing Director issued and maintained by the Director. Product quality, customer complaints etc. will be received by the Director who is the HACCP Team Leader. Based on the review results of the complaint by the HACCP amendments so done shall be recorded in the amendment sheet provided in all the copies of the manuals. It is the duty of the Director to issue the amended sheets to all the holders of the manual. The obsolete copies of the amended sheets shall be maintained by the Director. The HACCP Plan shall be updated once in a year and the updated version shall be authorized by the Managing Director

Definitions

To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP Plan.

The slaic vvhciciii uuncci pioctxluie aiu being “followed and criteria are being met.

Any action and activity that can be used to prevent or eliminate a food safely hazard or reduce it to an acceptable level.

Any action to be taken when the results of monitoring at the CCP indicate a loss of control.

A step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level.

A criterion which separates acceptability from unacceptability. Failure to meet a critical limit.

A systematic representation of the sequence of steps or operations used in the production or manufacture of a particular food item.

A system, which identifies, evaluates and controls hazards, which are significant for food safety.

A document prepared in accordance with the principles of HACCP to ensure control of hazards which are significant for food safety in the segment of the food chain under consideration.

A biological, chemical or physical agent in or condition of food with the potential to cause an adverse health effect.