The University of Virginia School of Engineering and Applied Science has discovered a method to create a versatile thermal conductor, which holds promise for more energy-efficient electronic devices, green buildings, and space exploration.

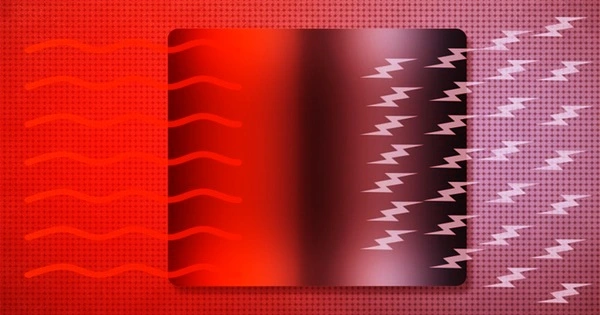

They have demonstrated that a well-known material used in electronic equipment can now also be used as a thermal regulator in its purest form. This new class of material allows engineers to change thermal conductivity on demand, transforming a thermal insulator into a conductor and vice versa.

The researchers published their findings in Nature Communications earlier this spring: Solid-state Bidirectional Thermal Conductivity Switching in Antiferroelectric Lead Zirconate is observed. The ability to control or “tune” thermal conducting materials in both directions will be especially useful in electronics and devices that must operate in extreme temperatures or withstand extreme temperature fluctuations. Space is one of the scenarios in which devices must perform under such harsh conditions.

“The temperature fluctuations in space can be pretty intense,” said Kiumars Aryana, who earned his Ph.D. in mechanical and aerospace engineering at UVA this spring and is first author of the Nature Communications paper. “This type of thermal transport technology could be a huge advantage as we build vehicles and devices for space exploration.”

We attempted to test bi-directional thermal conductivity using a commercial sample of lead zirconate, but it did not work. Using Lane’s sample, we achieved a 38% bi-directional change in thermal conductivity in one burst, which is a huge leap.

Kiumars Aryana

“A great example is the Mars Rover,” Aryana said. Ground temperatures at rover landing sites can reach 70 degrees Fahrenheit during the day and -146 degrees Fahrenheit at night. The rover relies on an insulating box and heaters to keep electronic devices from freezing and radiators to keep them from burning up during these extreme temperature swings.

“This new mode of heat management is significantly less complex, making heat regulation easier – and faster. Whereas a radiator or insulation takes a long time to heat or cool, a solid-state mechanism would heat or cool almost instantly. It is also safer to be able to keep up with the rapid temperature changes. Because the heating and cooling systems can keep up, the chances of malfunctions – or worse – are reduced” Aryana stated.

Meanwhile, promising applications on Earth include managing heating and cooling on a large scale, such as buildings, and a small scale, such as circuit boards for electronics. Less energy means more environmentally friendly technology and lower costs.

This advancement builds on a long-standing collaboration between Jon Ihlefeld, associate professor of materials science and engineering and electrical and computer engineering at UVA Engineering, and Patrick E. Hopkins, Whitney Stone Professor of Engineering and professor of mechanical and aerospace engineering and Aryana’s advisor.

Over the course of a decade, the Ihlefeld-Hopkins group has pioneered tunable thermal conductivity in crystalline materials, first at Sandia National Laboratories and now at UVA. Tunability is unique to a class of functional materials known as ferroelectrics, which Ihlefeld’s multifunctional thin-film research group specializes in.

“A ferroelectric material is like a magnet, except instead of a north and south pole, you have a positive and negative charge,” Ihlefeld said. An electric field, or voltage, when applied to a ferroelectric material, “flips” the polarity of the material’s surface to its opposite state, where it remains until an opposite voltage is applied.

“Typically, thermal conductivity is regarded as a static material property,” Hopkins explained. “To convert a thermal conductor to an insulator, you must permanently alter its structure or integrate it with a new material.”

Prior research by Ihlefeld and Hopkins demonstrated how to lower thermal conductivity with an electric field and how to integrate the material within a device to increase thermal conductivity, but they were unable to make the same material do both. The team used an antiferroelectric material for this project, in which heat and voltage both play a role.

“What this interesting material does, besides being a high-quality crystal with thermal conductivity trends like an amorphous glass and being solid-state, is it gives us two unique knobs to change thermal conductivity,” Hopkins explained. “We can use a laser to rapidly heat the crystal or apply voltage to actively tune thermal conductivity and heat transport.”

“We attempted to test bi-directional thermal conductivity using a commercial sample of lead zirconate, but it did not work,” Aryana explained. Lane Martin, Chancellor’s Professor of Materials Science and Engineering and department chair at the University of California, Berkeley, provided an extremely pure lead zirconate sample. “Using Lane’s sample, we achieved a 38% bi-directional change in thermal conductivity in one burst, which is a huge leap,” Aryana said.

Antiferroelectric material structures are naturally bidirectional. The smallest repeat unit of the crystal lattice has one half with the polarity pointing up and the other half with the polarity pointing down, so the positive and negative charges cancel each other out. The crystal structure changes when heated, and the antiferroelectricity disappears, increasing thermal conductivity. When an electric field is applied, the material transforms into a ferroelectric and its thermal conductivity decreases. When the voltage is removed, the net polarity returns to zero.

The flip in polarity and the arrangement of atoms in the crystal that support the anti-ferroelectric structure leads to observable and measurable thermal scattering events — something like a heat signature — which means energy diffuses through the material in ways that can be predicted and controlled.

Members of the Hopkins’ experiments and simulations in thermal engineering research group have made significant advances in laser material measurement. The Nature Communications paper describes an advancement in optical thermometry-based experiments in which students used a third laser to cause a rapid heating event that modulated the antiferroelectric film through the transition from antiferroelectric to paraelectric structure, allowing it to become polarized in the presence of an applied electric field.

Engineers will need a larger “on-off” switch to rapidly move or store a much larger percentage of heat in order to have an impact on technologies. The research team’s next steps will be to better define the material’s limitations so that they can design a new material with higher switching ratios, thereby accelerating the use of actively tunable thermal conductivity materials.