“Aarong”, formed in 1978, had established themselves one of the biggest cooperative groupings in the fair trade sector in Bangladesh. It‟s vision to help the artisans to help themselves by restoring their pride and self-esteem, reviving Bangladesh‟s traditional Art and Craft. Another aim was to confirm the women right and to establish them as a valuable asset in the society.

The primary objective of this report is to discuss the compliance activities of Aarong and analyze the service of various departments of Aarong for its producers. Aarong considers the Independent Producer (IPs) as their one of the important stakeholders who plays a vital role for producing and delivering the valuable goods for precious customers. It is basically the study of producer‟s feedback on different department and analyzes the services which are received by them. At the same time, it is also examined on the basis of this feedback that how Aarong can

improve the efficiency level in the process of giving order to the producers and receiving these orders from them as well as giving their payment.

This report is prepared on the basis of study on different departments such as design, tailoring, costing, merchandise order, quality control, finishing store and accounts department. Beside that I also give recommendation of different problems which are found on the basis of producer‟s feedback and observation of the activities.

INTRODUCTION:

Aarong is a pioneer name of Bangladeshi heritage and tradition of craft industry. Aarong is an organization that is dedicated to change the lives of disadvantages, promoting traditional products from Bangladesh and opening the doors so their products can be exported. Aarong is one of the social enterprises of BRAC, which has started its journey in 1978 with the purpose of creating economic opportunity for disadvantaged artisans and rural women through the revival and promotion of their traditional handicrafts.

“To provide a stable and gainful source of employment for the under privileged rural artisans, lift up the traditional identity and the commitment of quality service”

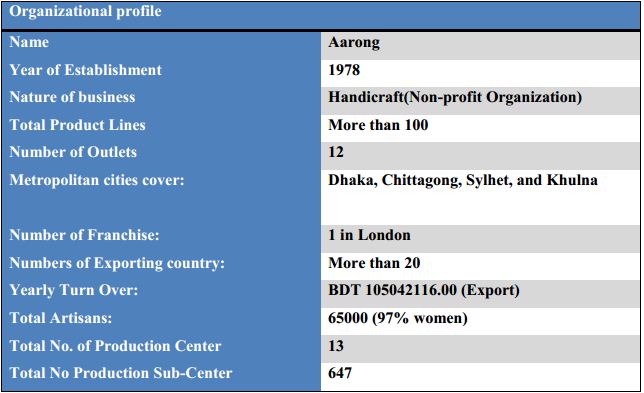

By keeping this principal ahead on their journey, currently Aarong supports over 66, 000 Bangladeshi artisans of whom 97 percent are women. Through a network of 647 production subcenters and 13 production centers, Aarong has developed a platform for the underprivileged artisans across more than 2000 villages of Bangladesh, where they can utilize their indigenous skills to earn a living.

Throughout Bangladesh and in international destinations, the name of Aarong is the synonym of quality originality and uniqueness. The designer and the creators of the product range offered by Aarong, have not only established the organization as leaders in deshi handicraft, but have also reignited interest and popularity for styles and traditional crafts that are native to the country. It is the gracious blend of contemporary and customary that ensures that each product is original and saleable in modern society. Aarong‟s product designs has brought consumer attention back to the products and styles that are indigenous to Bangladesh, its designers blending the traditional with the contemporary in a manner that has won instant consumer appeal, starting a revolution in trends that has now been taken up by countless other boutiques and stores

The name of the organization Aarong is a Bangla word. It means “a village fair or market”. The village fair provides craftsmen of all trades a marketplace to display and sell their traditional handicrafts. The naming of Aarong as such upholds the organizations commitment to promote the indigenous goods of our country, which are a part of our rich cultural and artistic heritage.

Organizational profile

Products and services of Aarong:

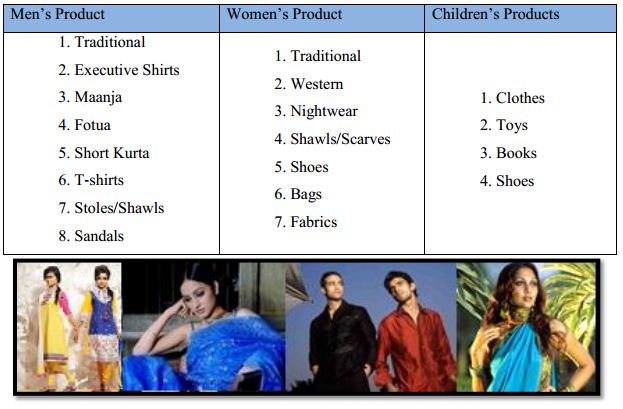

Holding the steadfast to its original Mission, Aarong today supports the lives and livelihoods of thousands of rural artisans and handicraft producers. These producers and artisans create wide range of products for the different types of consumers in home and abroad. The products are unique and traditional and appealing to the modern consumers, staring from clothes, accessories to home wares. Aarong designs and creates clothes for women, men and children.

There are designers and more than 3000 weavers across the country are involved with the production of Aarong clothing lines. And for the fashionable accessories there is one special department called jewelry department where jeweler creates elegant jewelries that are contemporary yet traditional using gold, silver and jewels like pearl, emerald and diamonds. The other accessories like bag, sandals and produced in AAF centers using leather, jute, bamboo etc. In home ware and decorative Aarong produces pottery vases and sculpture of wood, bamboo, brass and clay etc.

For exporting the products Aarong has a separate department in head office and very skillful artisans work here to produce fine quality products and these are sent to the production centers as sample of the exporting products. Here is the list of products Aarong produces:

Home Wares, Furniture, Others:

Social Compliance & Producer Relations (SCPR):

Now a day‟s compliance is essential for any organization to be successful in present legal environment. It can be treated as a mode of defining both individual and group behaviors to ensure the organization‟s applicable laws and policies are followed. Keeping thought in its journey, Aarong had taken a decision to established Social Compliance and Producer Relations (SCPR) department. As a social enterprise, Aarong also follows social compliance guidelines

that have been established to meet its commitment towards being a socially accountable organization for all of its respective stakeholders – producers, artisans, employees, customers, and community. This important responsibility has been carried out by the department of Social Compliance & Producer‟s Relations (SCPR) of Aarong. Beside that as a customer focus organization, the thought of forming SCPR department is to ensure that customers can purchase

product from Aarong with a clean conscience. As a result SCPR also responsible to ensure that the production centers where manufacturing activities take place are operating in standards that are acceptable to society without exploitation taking place. The working environment, terms and conditions, wage levels, worker benefits, health and safety facilities, working hours and worker development are all standardized and implemented by its producers. SCPR department has started its journey in 2009 of August.

Objective of SCPR:

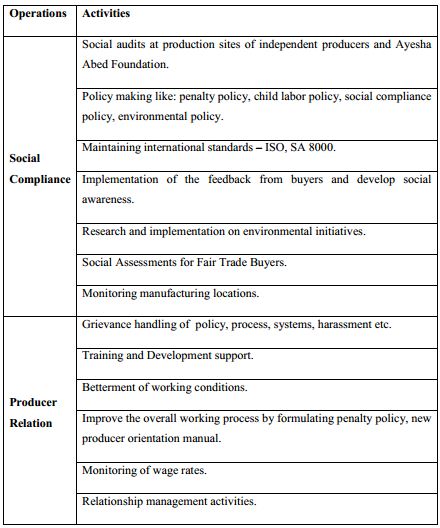

The main purpose of SCPR department is to ensure that Aarong‟s practices are associated with its mission by developing policies that adhere to social compliance standards. Beside compliance guideline should be followed by the Ayesha Abed Foundation (AAF) and independent production sites. In addition, SCPR also serve as relationship manager for independent producers by providing forums for producers to express their needs, handle producer grievances and improve producer related services.

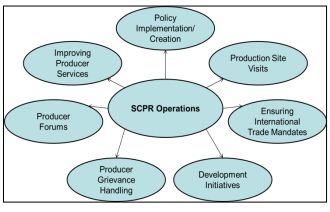

Operation of SCPR:

Aarong ensures that as a socially responsible organization, it fellows and practices best compliance standards for delivering product to ultimate consumers. This important responsibility of maintaining this commitment has been carried out by the department of Social Compliance & Producer‟s Relations (SCPR) of Aarong through undertaking following operations:

The total operation of SCPR is divided into two different parts; one is playing social compliance role and another is developing producer relations activities.

REPORT PART

Introduction:

As a part of producer‟s relation activity, social compliance & producer relations department has taken an initiative to evaluate the service level of producer from various departments. At the same time, SCRP tries to analyze the current operational flow of Aarong‟s Central Service (CS) as well as tries to figure out how Aarong can enhance its overall efficiency level by establishing fruitful coordination among the various departments. Beside that the precious feedback of Aarong‟s valuable producers is also considered for examine the service of CS. Starting from designing to ultimate product delivery; producers have to interact with various department of Aarong‟s CS. For this study, those departments of Aarong have considered from which producers interact directly for production purpose and product

delivery. We can expect that, from this study and observation both Aarong and producers of Aarong will be benefitted for increasing their efficiency level. Here, the marked departments are considered for evaluating and observing for conducting survey on producer’s service.

Objective of Survey:

The main purpose of this survey is to find out service level of each department of Central Service (CS) from the perspective of the producers. At the same time we are also interested to know the overall satisfaction level on the process that producers follow starting from design department to accounts department. In order to evaluate the overall process of CS system and understand the total process, it is very important to analyze the all department of CS system where producers need to interact to work with Aarong. We have found that producers need to interact with 8 different departments during the overall process the goods delivery and receiving the payment.

As a technique of collecting data we follow survey method beside observation. For this reason, survey questions are prepared for each department in order to take feedback from the producers.

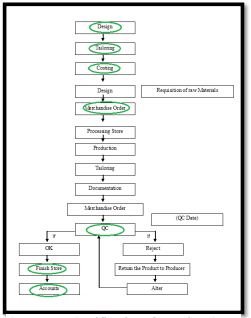

Operational flowchart of Central ServiceThere are six key areas on which survey has been emphasized, like:

- Behavior of employee with producer

- Time efficiency of the overall process

- Helpful or positive experience of producers

- Effectiveness of the process in the eyes of the producers

- Arrangement of space which would be helpful to understand the function of eachdepartment

- Feedback of producer‟s for the improvement of CS system

Methodology:

This report has been prepared based on both primary and secondary data. The primary data was collected through conducting survey in form of questioner, taking feedback from producers, observing various departments as well as collecting information from various department personnel during different tasks that I had to carry out as an intern. At the same time, I personally took notes during the tasks I came across in my internship. There are data that I collected from secondary sources such as reports, publishes documents of library of Aarong, internet and articles.

Data collected from the organization and other sources were assembled and put down in different part of the report. Based on the collected information analysis and conclusion is completed. Here are the details of survey procedure.

Sampling procedure: Producers of Aarong are the targeted population.

- Total no. of population=716

- Total number of department considered for evaluation= 7 departments

- Respondent: From each department 25 producers will be selected for taking feedback.

Among the 25 producers, producers are collected in proportioned way on the basis of producer‟s category.

Sample size is (n) = 25*7= 175

Data will be collected by using simple random sampling without replacement method. So that it will provide unbiased estimators of the population mean and variance. Another reason behind is that the total population size is sample. So that sample size will provide better representation.After deciding sampling procedure, we have prepared question paper for conducting survey.

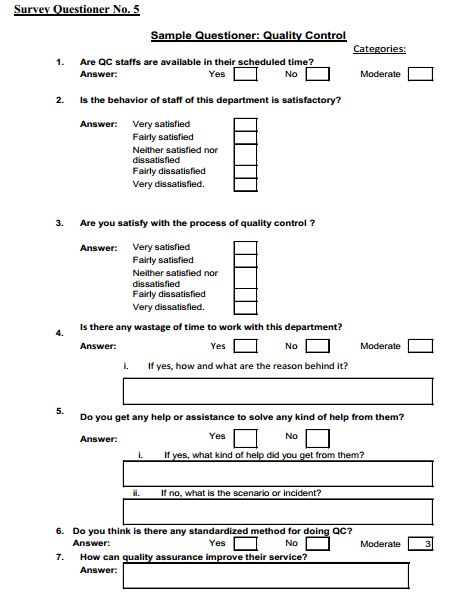

Survey question:

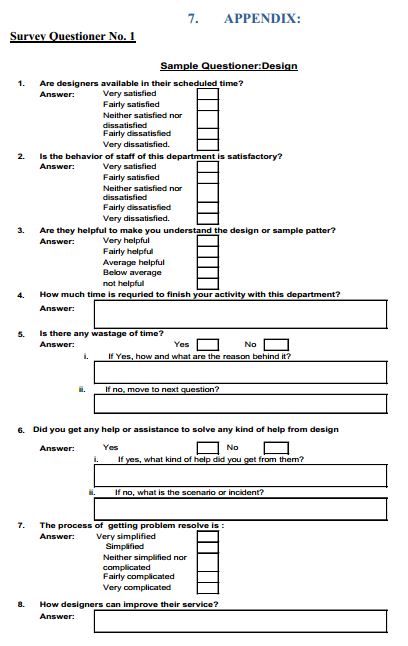

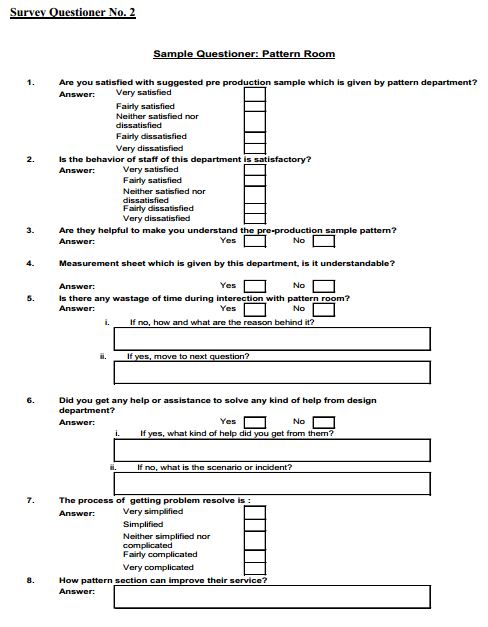

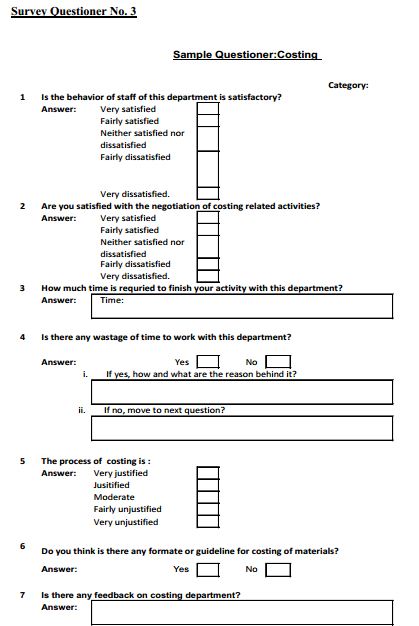

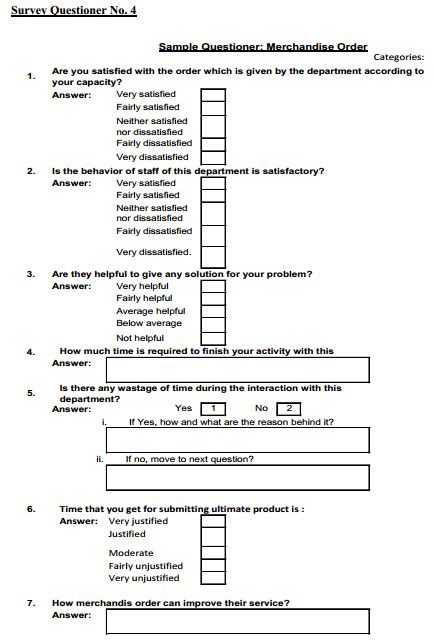

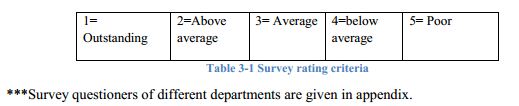

As there are eight different departments, like: design, pattern room, costing, merchandise order, processing store, quality control, finishing store or warehouse and accounts as well as 16 different categories of producers, 8 different survey questioner has prepared for collecting their feedback. Each of the survey question form is comprised of multipoint rating question, open ended and suggestion question. Multipoint rating questions are justified on the basis 5 scale rating system. Like: 1 is considered as positive experienced or satisfactory situation where 5 is measured as negative or non-satisfactory situation.

Following rating procedure is decided for identifying the outcome, like:

FINDINGS AND ANALYSIS:

Design Department:

Design department is one of the prominent sections where producers from all categories have come starting from the purpose of design development, understanding and making sample, sample approval etc. In order to improve CS service and efficiency for producer, at first we need to analyze the current scenario of design department. For this reason, we conduct a survey on producer to take feedback from them. At the same time observation is carried out on design department and its process.

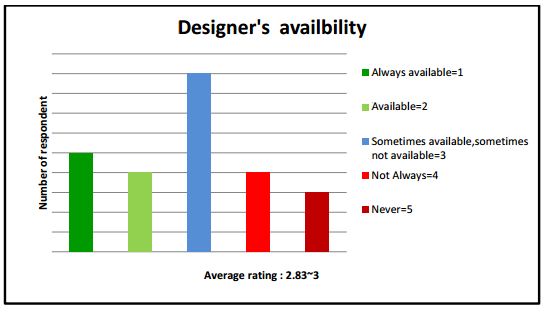

Designer’s availability: For the purpose of analyzing the designer availability for producer, producers have been asked a question whether designers are available in their scheduled time or not. On availability portion of survey, 2.86~3 score has been given by the respondents on an average which means producers are not satisfied enough. Recently producers of Aarong have been given a schedule which is called “Designer Schedule” for meeting with the designers in their available time for the purpose of consultation, taking instruction for making sample, sample approval, sample delivery etc.

Following outcomes are found through survey:

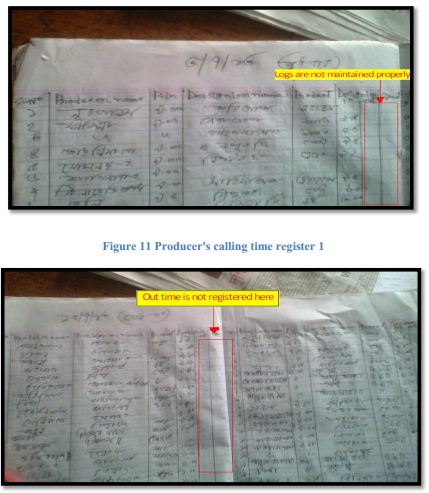

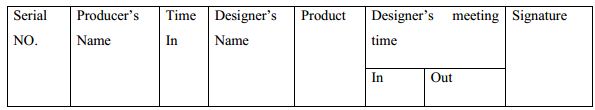

Majority of the producer has stated that they are not able to meet designer in the scheduled time. In order to meet with designer, they have to wait for longer period of time which hampers their other activities. As a cause of this unavailability producers have mentioned that there is no equal distribution of producer among the designer for monitoring. Sometimes designer are unavailable due to their meeting which is not informed to producer by designer earlier. As a result producer has to wait for long period of time or even has to go back without meeting designer after waiting for entire day. Beside that producers are also claimed that serial for waiting is not maintained properly. Though there is “Producer Calling Time Record Register” which is used to keep proper record for producer‟s entrance and meeting time, this register is not maintained properly. As evidence we can see following picture:

At present, the format of producer‟s calling time record register is:

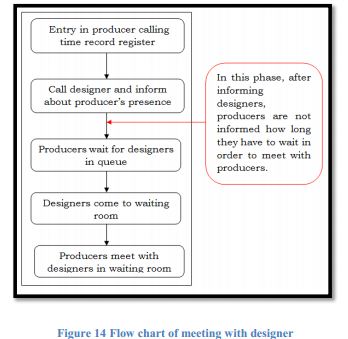

As a result, some of the producers have to wait for hours; some of them can complete their task with designer quickly. In addition, producer has also despondent with designer schedule, as there is fixed time for meeting with designer, if there any emergency for consulting, producers are not able meet with designers. Beside, sometimes designers also disagree to meet with producers except the schedule time. So producers think that present designer schedule does not offer enough flexibility or does not fulfill their actual purpose. Here is the following flow chart of

meeting with designers:

In addition, during observation it has been found that producers are summarized following points which are responsible for this scenario:

- Under each of the designer, there are huge numbers of producers for supervision.

- Meeting with producers is prioritized as important task compare to other task.

- Due to fixed time for meeting with designer, producers are not able to get sufficient time for consultation.

- Designers are not available in their desk though producers are in queue.

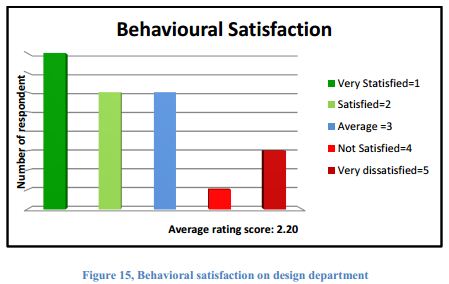

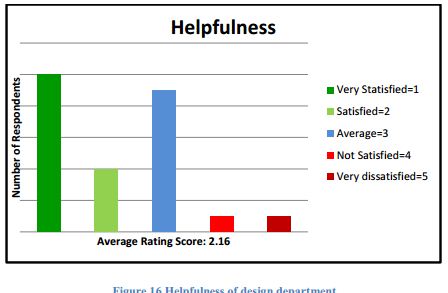

Behavioral and Helpfulness attitude: In order to analyze the behavioral aspect of design department, producers have been asked question on behavioral issue and helpfulness attitude of design department. One is whether the behavior of the department is satisfactory or not and does producer get sufficient help from the designer to understand the design or sample pattern?“Designers are helpful to understand the sample”

In the survey, 2.20 score has been given by producers which indicates that producers get sufficient help from designers for understanding the sample instruction. It also reflects that producers are satisfied enough on the effort of designers for giving proper direction and assistance to understand the design of sample. At the same time, majority numbers of producers are satisfied with the behavior of employee of design department. We can easily measure the outcome from the following charts:

Beside that producers get sufficient support from design depart when they go for any kind of assistance. In helpfulness portion, design section has scored 2.16 point which also shows that design department has satisfactory level of helpfulness attitude to solve producer‟s problem.

On the other hand, if we want improve the satisfaction level of producers; we need to focus on feedback of minority respondents who are not satisfied with behavioral issue. For example: sometimes producers are called not in honorable way which may also hurt them. Since Aarong has to deal with various types of producers, they should be treated in well manner. Besides that, when producers receive any kind of feedback for wrong outcome from the designer, the concern person should explain the issue to producer carefully and handle it carefully. As a result,

producers will be motivated and inspired by the designer. In addition, a training session can be arranged for the employee regarding the ways of dealing with different types of producers.

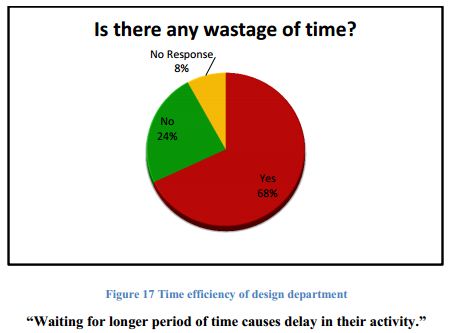

Time efficiency: One of the purposes of our survey is to judge the time efficiency of design department, so that producers have been asked is there is any wastage of time during the interaction with design department. We have found that 68 % of respondents claimed that they wastage their maximum time during the period of interaction with design department.

When one producer comes to Aarong with some specific purpose, he may have time limit as well as need to interact with other departments also. But it has been observe that in design section, producers need to wait for longer period of time when they come to meet with designers. On an average this waiting period is 2.5-3 hours for per producers. During the period of waiting in queue, producers cannot move to anywhere as they are not informed how long they need to wait.

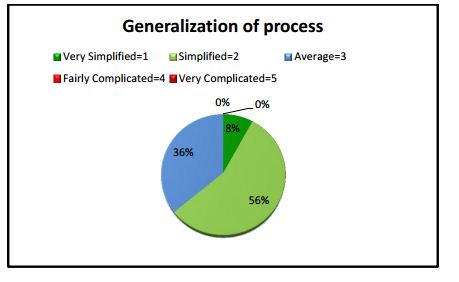

Generalization of process: Another aim of the survey on design department is to know the nature of overall process of design department and to identify whether the operational process of design department is simplified enough to the producers according to their understanding level. On an average producers have given 2.28 score for the nature of process which signify that producers are satisfied with present operational process of design department.

Suggestion form producers: Besides all, we also collect feedback from produces on how the particular department can improve from the perspective of producers. They have suggested various concerns. Among all, one of the major issues is identified is that producers need to wait for longer period time for sample approval. Producers would be benefited if the sample approval time can be minimized. If the sample approval time can be minimized, producer will be able to move towards next step that is preparing costing sheet.

Recommendation:

Here are the following suggestions which may help to improve the service of producers from design department:

- There should be emergency meeting scope or flexibility for the producers to meet with designers in order to fulfill their emergency need. Sometime, produces have to wait for a day long to consult with designer which might be required 10 to 15 minutes to fulfill the task.

- Producers should be distributed among the designers for monitoring in such a way that all producers can get similar level of attention from the designers.

- There should be system or scope to know designer‟s availability for next day. So that producers can take appointment time from the designer. As a result, producer‟s time would not be wasted.

- Work of the design department should be organized in such a way that meeting with producers should be treated as one of the prioritized task.

Merchandise order:

Merchandise order is another significant department of Aarong where producers need to visit for solving their order related activities. In this department, producers need to submit their production capacity and merchandise order section fixes a capacity level corresponding with their previous performance status. Then order sheet will be issued based on the target, requisition quantity, costing sheet and work sheet which are provided to producers. By focusing the purpose for the production, producers will negotiate the delivery date of the product with appropriate lead time.

After completing the production before the actual delivery date, producers need to inform merchandise order as well as need to set appointment date for quality checking which will be carried by the quality control (QC) department. But on the other hand, if there is any product which is rejected by QC department or which is needed to be altered then producers again should come to this department for taking new QC appointment time. Beside these activities,

merchandise order also has other responsibilities like: creating product code, conducting loan assessment activities, executing penalty policy, monitoring producers for on time delivery, product distribution and so one.

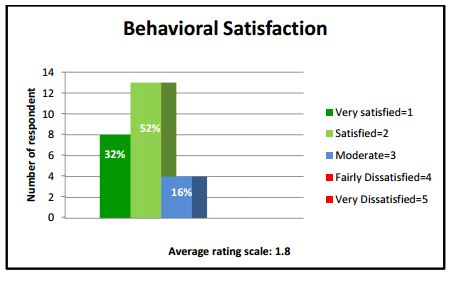

Behavioral aspect: Similarly to other department, survey is also taken place among the producers regarding merchandise order. In the behavioral section of the survey, this department has scored on an average 1.8 from producers which represent that producers are satisfied on the behavioral aspect of merchandise order. From the graph we can see that, 32% producers are very satisfied, 52% of them are satisfied and rest of 16% are moderate satisfied with the behavior of merchandise order.

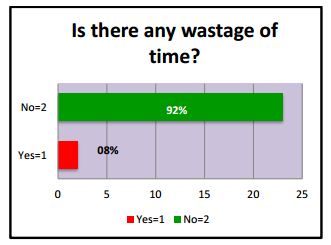

Time efficiency: Moreover 92% producers that they get their service effectively when they go to merchandise order department for any query. They think that there is no wastage of time or they do not need to wait for long time. Only 08% producers think there is wastage of time in terms of waiting, delay to get service. Here is the graphical presentation of below outcome:

Helpfulness attitude: In term of helpfulness merchandise department has got 2 which denote that producers get sufficient support from them and they are pleased with it. In detail we can see that 24% producers think merchandise order is very helpful, 44% producers express that they get producers have moderate agreement on the

helpfulness of merchandise order.

Recommendation:

Following suggestions are given for merchandise order department to minimize the present hitches:

- Producers can be divided into full time and casual or temporary basis. Though producers are pleased with the delivery deadline, they wish that it would be better from them if their proposition is taken before giving their delivery date.

- As producers face problem during the off season or when product has less demand, the Eid or special order can be distributed in advance among the producers.

- Produces who do not have the expected capacity or skill or efficient, they need to be identified quarterly and identified producers should be give appropriate solution to improve their condition.

It would be better not only for merchandise order but also for all departments if ERP system is introduced soon

Quality Control:

Quality control department is one of the important depart in central service. The main objective of this department is to gain higher level customer‟s satisfaction by assuring best quality of product from the producers. For this reason, this department follows some rules and guideline for its quality management process. After taking appointment serial from merchandise order for doing QC, producers need to bring their goods next day to quality control department. After reaching to quality control department, producers need to take serial for quality checking. When

their serial comes, the QC staff will count the number of products brought by producer. Then QC staff will verify order sheet, costing sheet, product requisition sheet, sample approve piece, production approval card. Once the QC process has been completed, the accepted products will be billed and the rejected product will be returned to producer for alteration.

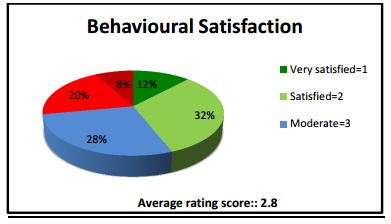

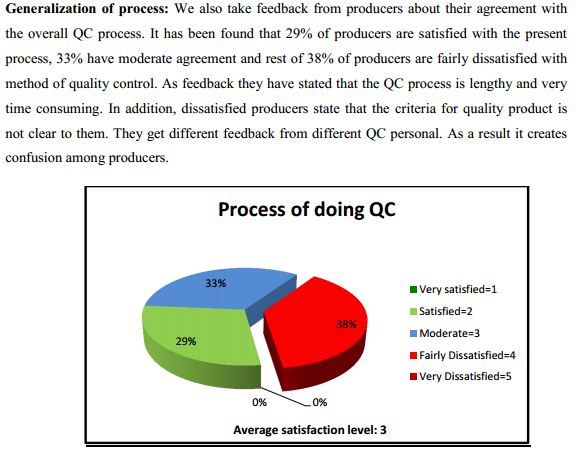

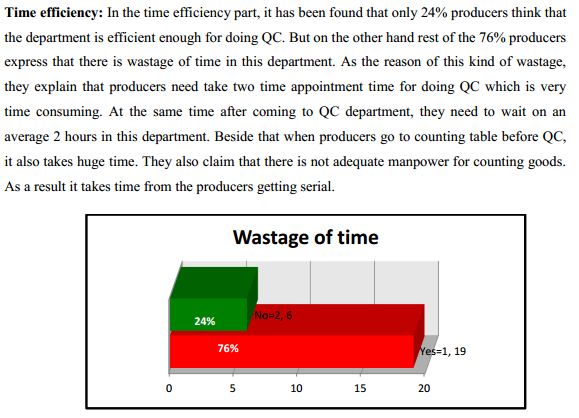

Behavioral aspect: First of all the behavioral satisfaction of producers, where this department has got moderate rating that is 2.8~3. Here 12% producers are very satisfied, 32% is satisfied, 28% is moderate, another 20% is dissatisfied and 8% producers are very dissatisfied.

Recommendation:

In order to improve the producer‟s satisfaction level, following recommendations can be taken as recommendation:

As produces need to take two times serial for doing QC of their products, it would be better, when serial is given to producers from merchandise order, at the same time QC personnel should be assigned by the system. Since, assigning process would be done and controlled by the system, there would be less issue of biasness and it would also help to minimize graveness from producers.

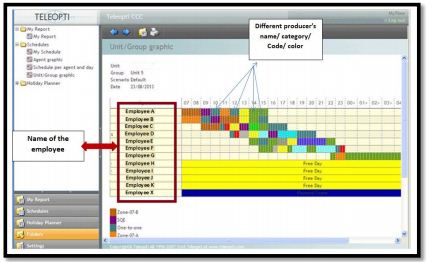

Beside to control manpower, Aarong can use system software like: TELEOPTI. So because of using this system work force management can be implemented for optimal use of timing.

As a demo we can see the below picture:

Through this system merchandise order can check how many QC personnel are available next day and assign producers according to their schedule. At the same time producer can know about the accurate timing of appointment. Here different color may be used to identify producer‟s code or category or quantity of good or name. Beside producers can be provided time with color code during taking the appointment for doing QC. Moreover, employee can see his schedule of next day. As a result, time of doing QC can be managed effectively.

BROAD-SPECTRUM RECOMMENDATION:

Apart from the above discussion and recommendation, producers also express their opinion for further betterment of the service of Aarong. As one of the objective of SCPR department is to develop better relationship with producers, following issues should be considered as recommendation for further development:

- In order to establish the freedom for express opinion of produces, Aarong should place „Suggestion Box‟ for producers at the suitable location for collecting their feedback. So that producers will be able to let Aarong know about their thought, share their problem as well as suggestion.

- Behavioral Training session regarding soft skill development can be arranged for the employee to dealing with producers. So that producer‟s satisfaction level on the service of different departments will be increased.

- Majority of the producers shares that they face problem with their goods because of insufficiency of space. Space is required for keeping producer‟s goods. So it is very important to increase space for keeping goods at Aarong‟s premises.

CONCLUTION:

Working with Aarong especially in this department has been a great experience for me. I got to learn about the basic compliance related activity and that will help me built my carrier in this section. After completing my internship successfully on the social compliance and producer relations department of Aarong, while I was writing this report, I found myself very much close with this Aarong and its artisans. The above project helps me to learn the comprehensive part of human resource management and one of the functional parts of it which is compliance. I have

also gathered experience on how compliance helps organization to become a successful fair trade organization like Aarong. Last but not the least designs your message in such a convenient way so that your target customers get emotionally attached with your product. So working with Aarong, in a one sentence was an exclusive scope for me to implement my studied knowledge in a practical field and gather experiences to strength my future.