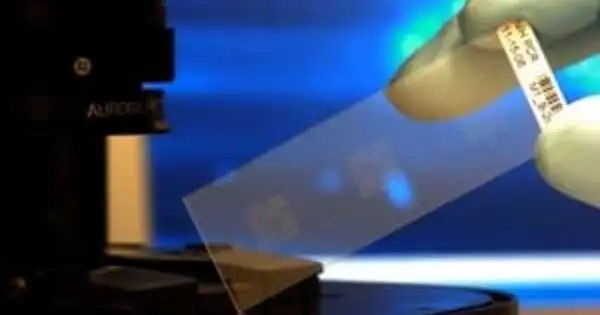

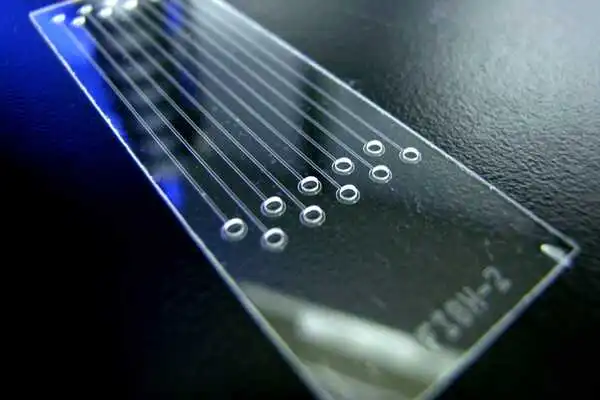

A fingertip-sized chip replaces bulky laboratory equipment. An infrared sensor has been developed that analyzes the content of liquids within a fraction of a second. In analytical chemistry, it is often necessary to accurately monitor the concentration change of certain substances in liquids on a time scale of seconds. Especially in the pharmaceutical industry, such measurements need to be extremely sensitive and reliable.

A new type of sensor has been developed at TU Wien which is highly suitable for this task and combines several important advantages in a unique way: based on customized infrared technology, it is significantly more sensitive than previous standard devices. Moreover, it can be used for a wide range of molecule concentrations and it can operate directly in the liquid. This is the consequence of its chemical robustness and thus provides data in real-time, i.e. within fractions of a second. These results have now been published in the scientific journal Nature Communications.

Different molecules absorb different wavelengths

“To measure the concentration of molecules, we use radiation in the mid-infrared spectral range,” says Borislav Hinkov, head of the research project from the Institute of Solid State Electronics at TU Wien. This is a well-known technique: molecules absorb specific wavelengths in the mid-infrared range, while other wavelengths are transmitted without attenuation. Thus, different molecules have their very specific “infrared fingerprint.” By accurately measuring the wavelength-dependent absorption strength profile, it is possible to determine the concentration of a particular molecule in the sample at any given time.

We only need a few microliters of liquid for a measurement. And the sensor delivers data in real-time – many times per second. Thus, we can precisely monitor a change in concentration in real-time and measure the current stage of a chemical reaction in the beaker. This is in strong contrast to other reference technologies, where you need to take a sample, analyze it and wait up to minutes for the result.

Borislav Hinkov

Infrared spectroscopy has routinely been used in gas sensing for a long time. The new achievement of the team at TU Wien is the implementation of this technology on a fingertip-sized sensor chip, which is specifically suitable for liquid sensing. Developing such a sensor was a technological as well as an analytical challenge, because liquids absorb infrared radiation much stronger than gases. The compact liquid sensor was realized in collaboration with Benedikt Schwarz from the Institute of Solid State Electronics and fabricated in the Centre for Micro- and Nanostructures, the state-of-the-art cleanroom of TU Wien.

“We only need a few microliters of liquid for a measurement,” says Borislav Hinkov. “And the sensor delivers data in real-time – many times per second. Thus, we can precisely monitor a change in concentration in real-time and measure the current stage of a chemical reaction in the beaker. This is in strong contrast to other reference technologies, where you need to take a sample, analyze it and wait up to minutes for the result.”

Collaboration between different disciplines is the key

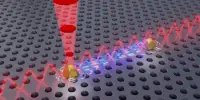

This was made possible by a collaboration between the departments of electrical engineering and chemistry at TU Wien: the Institute of Solid State Electronics has extensive experience in the design and fabrication of so-called quantum cascade lasers and detectors. They are tiny semiconductor-based devices that can emit or detect infrared laser radiation with a precisely defined wavelength based on their micro- and nanostructure.

The infrared radiation emitted by such a laser penetrates the liquid on the micrometers-length scale and is then measured by the detector on the same chip. Using these specially combined ultra-compact lasers and detectors, a sensing device was realized, and its performance was tested in first proof-of-concept measurements. The work was conducted in collaboration with the group of Bernhard Lendl from the Institute for Chemical Technologies and Analytics.

Experimental demonstration: a protein changes its structure

To demonstrate the performance of the novel mid-infrared sensor, a reaction from biochemistry was selected: a known model protein was heated, thereby changing its geometrical structure. Initially, the protein has the shape of a helix-like coil, but at higher temperatures it unfolds into a flat structure. This geometrical change also changes the particular mid-infrared fingerprint absorption spectrum of the protein. “We selected two suitable wavelengths and fabricated suitable quantum-cascade-based sensors, which we integrated onto a single chip,” says Borislav Hinkov. “And indeed, it turns out: you can use this sensor to observe the so-called denaturation of the selected model protein with high sensitivity and in real time.”

The technology is extremely flexible. It is possible to adjust the necessary wavelengths as needed in order to study different molecules. It is also possible to add further quantum cascade sensors on the same chip to measure different wavelengths and thus distinguish the concentration of different molecules simultaneously. “This opens up a new field in analytical chemistry: Real-time mid-infrared spectroscopy of liquids,” says Borislav Hinkov. The possible applications are extremely diverse — they range from the observation of thermally induced structural changes of proteins and similar structural changes in other molecules, to the real-time analysis of chemical reactions, for example in pharmaceutical drug production or in industrial manufacturing processes. Wherever there is the need to monitor the dynamics of chemical reactions in liquids, this new technique can bring important advantages.