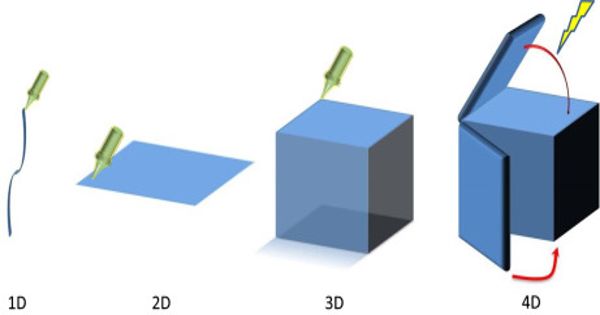

4D printing is the process through which a 3D printed object transforms itself into another structure over the influence of external energy input as temperature, light, or other environmental stimuli. It is also known as 4D bioprinting, active origami, or shape-morphing systems, uses the same techniques of 3D printing through computer-programmed deposition of material in successive layers to create a three-dimensional object. The process of 4D printing is essentially the same – it utilizes the same 3D printers, and the computer runs the same program to deposit material in successive layers until a 3D structure is formed.

4D printing adds the dimension of transformation over time. However, 4D printing adds a new dimension, where the structure can change its shape over time. It is therefore a type of programmable matter, wherein after the fabrication process, the printed product reacts with parameters within the environment (humidity, temperature, etc.,) and changes its form accordingly. It requires unique materials and customized designs to be built into the program to prompt the 3D print to change shape when triggered by a specific stimulus, such as heat, water or light. 4D printing technology uses commercial 3D printers, such as Polyjet 3D printers. The input is a “smart material”, that can be either a hydrogel or a shape memory polymer.

Advantages of 4D Printing

- Size changing – The most obvious advantage of 4D printing is that through computational folding, objects larger than printers can be printed as only one part.

- New materials = new properties – Another advantage of this technology is the usage of possible applied materials. 4D printing has a vast potential to revolutionize the world of materials as we know it today.

4D printing technology is still very much in the early stages of research and development. Currently, the only places likely to house 4D-printed forms are laboratories and prototyping facilities, as well as some architectural exhibitions and art installations.

While 3D printing contains the instructions to print layers of material successively, 4D printing adds a precise geometric code to the process based on the angles and dimensions of the desired shape. The ability to do so arises from the near-infinite configurations at a micrometer resolution, creating solids with engineered molecular spatial distributions and thus allowing unprecedented multifunctional performance. It gives the shape memory and instructions on how to move or adapt under certain environmental conditions.

Information Source: