Mining waste, also known as tailings, is a byproduct of mining operations that contains minerals and metals that are often difficult or expensive to extract using traditional methods. However, recent research has shown that microbes can be used to unlock the value in mining waste and recover valuable resources.

Researchers have developed a new mining technique that uses microbes to recover metals and store carbon in mining waste. Adopting this method of reusing mining waste, known as tailings, has the potential to transform the mining industry and create a greener, more sustainable future.

Mining waste is known as tailings. They are fine-grained waste materials that remain after extracting the target ore mineral and are then stacked and stored. This is known as dry-stack tailing. Mining practices have evolved and become more efficient over time. However, the climate crisis and increased demand for critical minerals necessitate the development of new ore extraction and processing technologies.

This technique makes better use of both current and past mine sites. This technology has the potential to be a game changer in the fight against climate change, and the mining industry has a unique opportunity to play an important role in green energy’s future.

Dr. Jenine McCutcheon

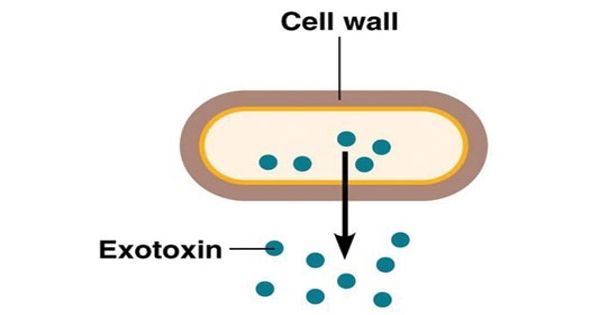

Old tailings contain higher levels of critical minerals, which can be extracted using microbes in a process known as bioleaching. The microbes aid in the breakdown of the ore, releasing any valuable metals that were not fully recovered in an environmentally friendly manner that is much faster than natural biogeochemical weathering processes.

“We can take previous tailings and recover more resources from those waste materials while also reducing the risk of residual metals entering local waterways or groundwater,” said Dr. Jenine McCutcheon, an assistant professor in the Department of Earth and Environmental Sciences.

In addition to improving resource recovery, the microbes capture carbon dioxide from the air and store it within the mine tailings as new minerals. This process aids in offsetting some of the emissions released while the mine was active and helps stabilize the tailings.

Microbial mineral carbonation could offset more than 30 per cent of a mine sites annual greenhouse gas emissions if applied to an entire mine. In addition, this microbial-driven technique gives value to historical mine tailings that are otherwise considered industrial waste.

“This technique makes better use of both current and past mine sites,” McCutcheon explained. “Rethinking how future mine sites are designed to incorporate this process could result in mines that are carbon neutral from the start, rather than considering carbon storage as an afterthought. This technology has the potential to be a game changer in the fight against climate change, and the mining industry has a unique opportunity to play an important role in green energy’s future.”

McCutcheon also believes that microbial-driven processes could help the mining industry transition to carbon-neutral or carbon-negative mining, but that industry participation is required to move this technology to a large-scale deployment.

However, there are still some challenges to overcome before this technology can be widely adopted. For example, researchers need to identify the best microbes for each specific type of mining waste, optimize the conditions for microbial growth, and ensure that the process is economically feasible. Overall, using microbes to get more out of mining waste is an exciting and promising area of research that has the potential to revolutionize the mining industry and make it more sustainable.