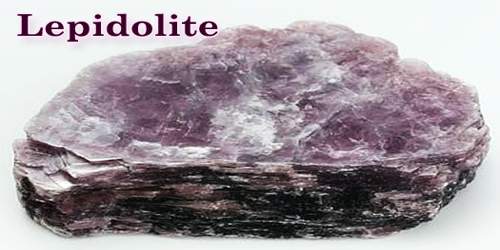

Cosmetic ingredients are typically intended for use in personal care and beauty products, and they are subjected to testing to ensure that they are safe for topical application to the skin. Cosmetic ingredients are not a standard or recommended practice for battery protection because these substances may not be suitable for the specific requirements of battery protection. A team of researchers created a battery electrode protective film out of biopolymers derived from cosmetic ingredients.

In cosmetics, xanthan gum, derived from plants such as cabbage and known for its carbohydrate content, acts as a natural protective barrier. This remarkable substance has recently been harnessed to create a protective shield for battery electrodes rather than the skin.

Professor Changshin Jo from the Graduate Institute of Ferrous & Eco Materials Technology and the Department of Chemical Engineering and Jooyoung Jang, a PhD candidate, from the Department of Chemical Engineering at Pohang University of Science and Technology (POSTECH), have crafted a protective film by blending polymers. This film enhances the durability of battery electrodes, and their research findings have been featured in the international journal Energy Storage Materials.

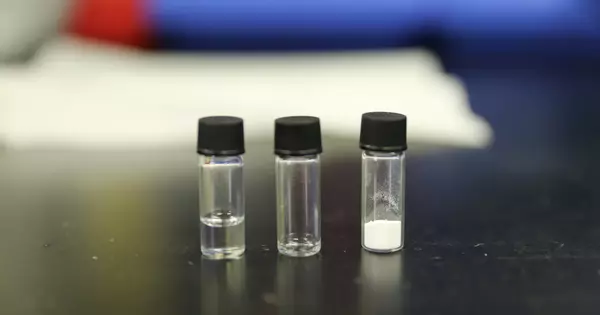

In this investigation, the research team employed the biopolymer xanthan gum in combination with an ionically conductive polymer to fashion a protective film for the battery electrode.

Professor Changshin

Due to the inherently intermittent nature of renewable energy sources such as solar power, the importance of energy storage systems (ESS) is steadily increasing. ESS technology allows for the capture and efficient use of electricity when it is required, making it a critical component in the utilization of renewable energy. While lithium-ion (Li-ion) batteries have traditionally been used for ESS, their high cost and concerns about lithium depletion have prompted ongoing research into alternative solutions.

Zinc (Zn), an abundant element on Earth, is one promising alternative to lithium. When compared to lithium-ion batteries, zinc-ion batteries can store significant amounts of energy and are less prone to fire. Nonetheless, achieving a consistent deposition of zinc on the electrodes in ESS batteries is a challenging task, and the repeated charging and discharging cycles tend to lead to the formation of twig-like crystals on the zinc surface, reducing the battery’s longevity.

In this investigation, the research team employed the biopolymer xanthan gum in combination with an ionically conductive polymer to fashion a protective film for the battery electrode. The interaction between these two polymers yielded a smooth protective layer on the electrode’s surface, effectively shielding it from physical impacts and chemical contaminants.

Furthermore, this protective film was high in oxygen functional groups, which aided in the uniform nucleation of zinc, resulting in efficient zinc deposition on the electrode surface. As a result, the formation of twig-like crystals on the zinc surface was significantly reduced, and the film exhibited remarkable stability even after 200 days of charging and discharging.

According to Professor Changshin Jo, “I hope that this research will contribute to the advancement of ESS technology for sustainable green energy production.”