Many medical conditions, such as aberrant gait and muscular abnormalities, necessitate reliable pressure sensing. Flexible pressure sensors that are simple, lightweight, and low-cost have gotten a lot of interest in this respect.

These sensors are designed and built utilizing conductive polymer composites as building blocks, a process known as “additive manufacturing” or “3D printing.”

3D printing, also known as additive manufacturing, is a method of layering a three-dimensional object from a computer-generated design. It’s an additive method that involves building up layers of material to form a three-dimensional object.

Subtractive manufacturing procedures involve cutting a final design from a larger block of material. As a result, there is less waste from 3D printing.

However, all 3D-printed pressure sensors that have been created thus far can only detect applied forces in one direction. For real-world applications, where forces can be applied in a variety of angles and orientations, this isn’t nearly enough.

Furthermore, most conductive polymers’ electrical resistance varies with temperature and must be adjusted for precise pressure detection.

The proposed 3D printing technology has a wide range of applications in energy, biomedicine, and manufacturing. With the incorporation of the proposed sensing elements in robotic grippers and tactile sensors, the detection of multi-directional forces along with temperature could be achieved, heralding the onset of a new age in robotics.

Prof. Hoe Joon Kim

A group of scientists led by Prof. Hoe Joon Kim from Daegu Gyeongbuk Institute of Science and Technology in South Korea addressed this issue with a newly designed multi-axis pressure sensor coupled with a temperature-sensing component that overcomes the limitations of conventional sensors, according to a study published in Composites Part B: Engineering.

“Our multi-axis pressure sensor successfully captures the readings even when tilted forces are applied. Moreover, the temperature-sensing component can calibrate the resistance shift with temperature changes. In addition, the scalable and low-cost fabrication process is fully compatible with commercial 3D printers,” explains Prof. Kim.

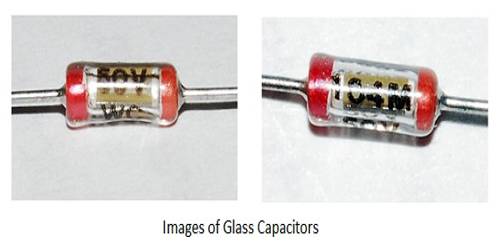

Multi-walled carbon nanotubes (MWCNTs) and polylactic acid were used to create the printable conductive polymer (PLA). They then used 3D printing to create the sensor body with a commercial elastomer and the sensing material with MWCNTs/PLA composite filament.

The sensor is made up of three pressure-sensing elements for multi-axis pressure detection and a temperature-sensing element for resistance calibration. It is based on a bumper structure with a hollow trough beneath it.

By assessing the response of each pressure-sensing device, the sensor was able to effectively calibrate both the magnitude and direction of the applied force. When put in a 3D-printed flip-flop and a hand gripper, this bumper construction allowed for a clear separation between various human motions and gripping activities.

The scientists are thrilled about the future prospects of their 3D-printed sensor.

“The proposed 3D printing technology has a wide range of applications in energy, biomedicine, and manufacturing. With the incorporation of the proposed sensing elements in robotic grippers and tactile sensors, the detection of multi-directional forces along with temperature could be achieved, heralding the onset of a new age in robotics,” comments an excited Prof. Kim.

Indeed, those are some interesting consequences to look forward to!